Tooling fixture selection method

A tooling and process technology, applied in the field of tooling and fixture selection, can solve the problems of irregular shovel foot and traction design, defects in the manufacturing process of parts, and random appearance and size, and achieve reasonable on-site layout, guaranteed strength and corrosion resistance. Sexual, easy turnaround effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

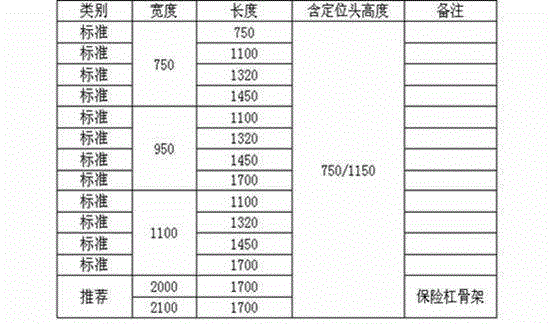

[0014] A method for selecting fixtures includes process requirements, color requirements, material requirements, structure requirements, and non-standard container appearance and size requirements.

[0015] Process requirements include steps and selection standards; pretreatment (rust removal, degreasing, etc.) - grinding - anti-rust paint - top coat, baking paint treatment, of which the anti-rust paint is E06 C53-31 red lead alkyd anti-rust paint, quality Standard ZB / TG51006-87; top coat is milky white alkyd enamel, quality GB / T25251-2010.

[0016] The color requirements include the place of use: the finish paint of fixtures and fixtures in the assembly workshop and welding workshop is made of milky white alkyd enamel, which is easy to manage and use.

[0017] Material requirements include material selection and specifications: use materials that meet national environmental protection requirements and safety performance requirements. High-elastic polyurethane casters must ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com