Underwater working robot

A technology for underwater operations and robotics, applied in the field of robotics, can solve the problems of inconvenient rapid replacement of end effectors, unrealized robot modular design, increased sealing difficulty, etc., to achieve strong passing performance and load capacity, and ingenious configuration , Easy to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

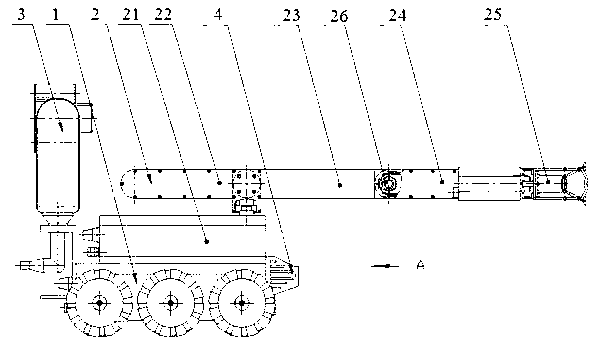

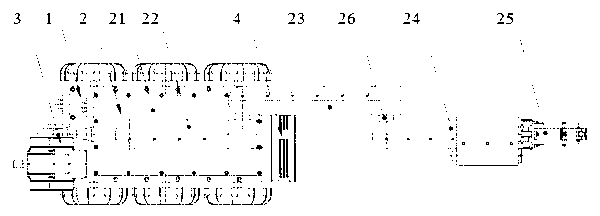

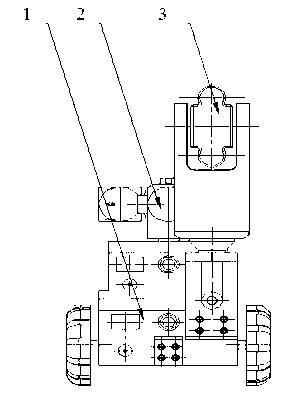

[0052] The robot is composed of a car body module 1, a manipulator module 2, an underwater camera module 3, a functional component module 4 and a control module 5. When handling general tasks, the robot is mainly assembled from the storage box 41 in the car body module 1, the manipulator module 2, the underwater camera module 3, and the functional component module 4. During the movement of the robot, the manipulator module 2 is folded above the car body. At this time, the external dimensions of the robot are 590mm×294mm×520mm in length×width×height. The outer dimensions of the robot body module 1 are 400mm×200mm×150mm in length×width×height, and wheels of different sizes can be selectively installed. In this embodiment, wheels with a diameter of 140mm are assembled, and the ground clearance is 35mm, which can realize 0-24m / min Continuously variable speed, climbing ability ≥ 30° on smooth steel plate.

[0053] The manipulator module 2 is composed of a base 21 , a waist 22 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com