High-concentration degradation-resistant organic wastewater treatment process

A technology for organic wastewater treatment and treatment process, which is applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. It can solve problems such as high investment and operation costs, difficult operation and management, and immature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

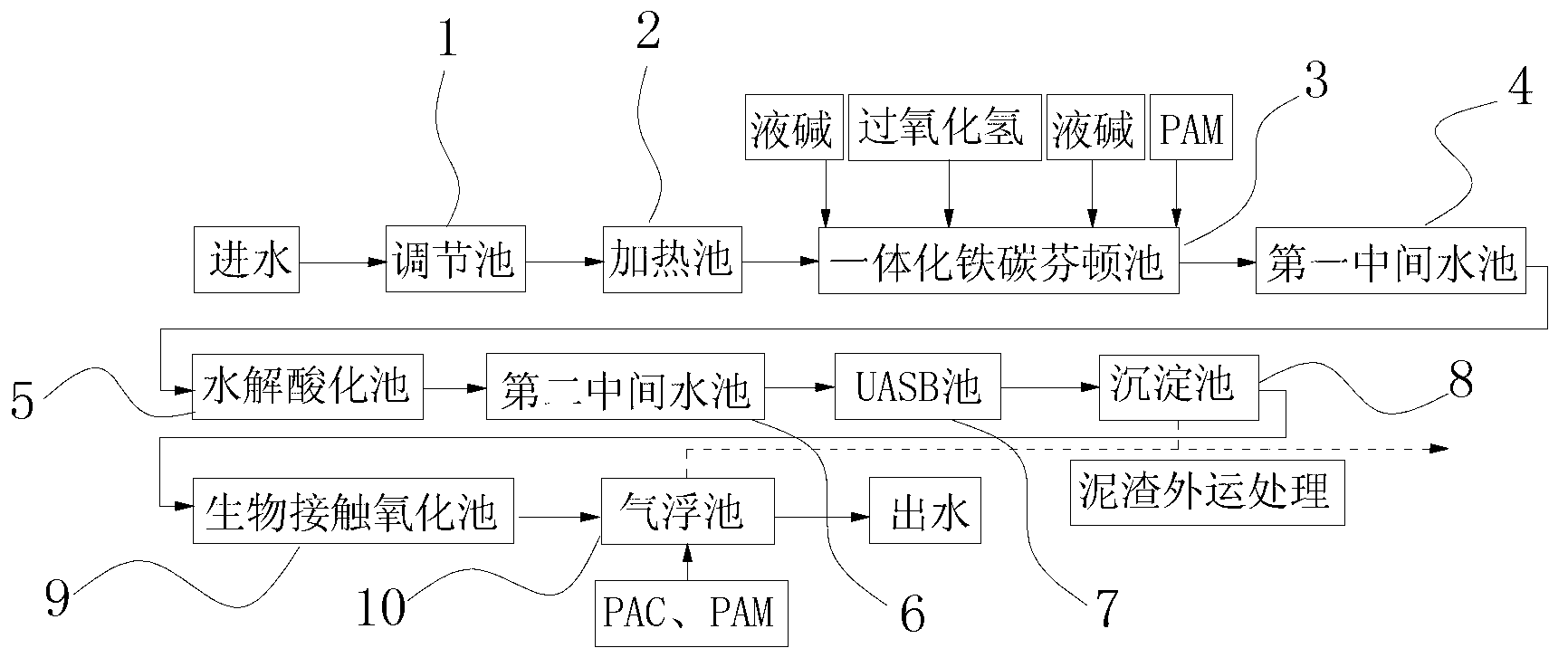

[0023] The embodiment discloses a high-concentration refractory organic wastewater treatment process, combining figure 1 , including the following 6 steps:

[0024] S1, the waste water is imported into the adjustment pool for homogeneous and equal quantity adjustment, and then sent into the heating pool to heat the organic waste water, and the heating temperature is 55 ° C to 60 ° C;

[0025] Through the heating treatment of high-concentration refractory organic wastewater, the toxic and harmful substances in the wastewater are hydrolyzed, destroying the toxic components that are harmful to microorganisms, and reducing the toxicity of wastewater;

[0026] S2. Adjust the pH range of the wastewater to 1~2, and the wastewater enters the integrated iron-carbon Fenton pool: first enters the iron-carbon pool for iron-carbon reduction electrolysis, and the ratio of iron filings and carbon in the iron-carbon pool is 1:1 by volume , the total amount of filling is 60% to 80% of the eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com