A process for segmental utilization of waste water from direct and reverse flotation of phosphate rock

A technology of positive and negative flotation and production wastewater, which is applied in flotation water/sewage treatment, flotation, solid separation, etc., can solve the problems that production wastewater cannot be cross-mixed, and achieve significant economic and social benefits and a safety factor High and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

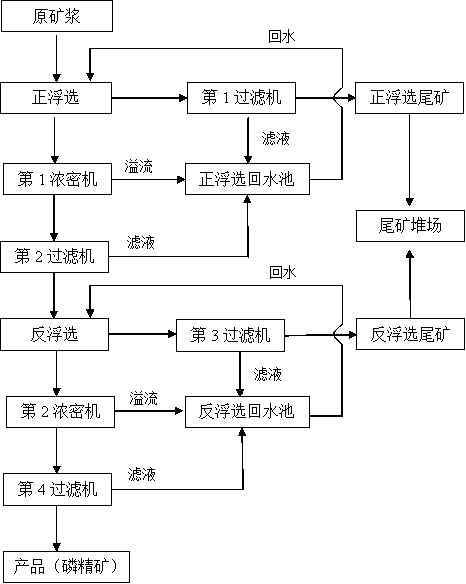

[0016] Embodiment 1, with reference to figure 1 , a segmental utilization process of phosphate rock positive and negative flotation production wastewater, the process mainly includes: after the raw ore is ground by a mill, the slurry that reaches the qualified particle size enters the flotation machine for positive flotation operation, and the product in the flotation machine tank After being filtered by the first filter, the filtrate enters the positive flotation backwater pool, the filter cake, that is, the positive flotation tailings enters the tailings stockyard, the foam product of the flotation machine enters the first thickener, and the overflow enters the positive flotation backwater pool. After the underflow enters the second filter for filtration, the filtrate enters the positive flotation return tank, and the filter cake enters the reverse flotation operation; after the reverse flotation flotation machine foam product enters the third filter for filtration, the filtr...

Embodiment 2

[0018] Embodiment 2, with reference to figure 1 , a segmental utilization process of phosphate rock positive and negative flotation production wastewater; a certain phosphate rock (P 2 o 5 20.98%) after being ground by a mill, the pulp with a fineness of -200 mesh accounting for 78% will enter the inflatable mechanical agitation flotation machine for positive flotation, control the pH value of the pulp at 9-10, add inhibitors and collectors , the product in the flotation machine tank enters the vertical automatic filter press (the first filter), the filtered filtrate enters the positive flotation return pool, and the filter cake enters the tailings stockpile. The water content of the filter cake is below 12%. The foam product enters the first thickener, the overflow enters the positive flotation return tank, the underflow enters the ceramic filter (the second filter), the filtered filtrate enters the positive flotation return tank, and the filter cake enters the slurry tank; ...

Embodiment 3

[0019] Embodiment 3: Refer to figure 1 The utility model relates to a segmental utilization process of waste water produced by positive and negative flotation of phosphate rock. A phosphate rock (P 2 o 5 15.23%) after being ground by a mill, the pulp with a fineness of -200 mesh accounting for 90% will enter the inflatable mechanical agitation flotation machine for positive flotation, control the pH value of the pulp at 9-10, add inhibitors and collectors , the product in the flotation machine tank enters the box-type automatic filter press (the first filter), the filtered filtrate enters the positive flotation backwater tank, and the filter cake enters the tailings stockpile. The water content of the filter cake is below 15%. The foam product enters the first thickener, the overflow enters the positive flotation return tank, the underflow enters the ceramic filter (the second filter), the filtered filtrate enters the positive flotation return tank, and the filter cake enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com