Method for treating food industrial wastewater by synergy of supercritical water oxidation and membrane separation

A supercritical water oxidation and co-processing technology, which is applied in food industry wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as not being able to meet drinking water needs, and achieve high production efficiency and treatment efficiency High, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

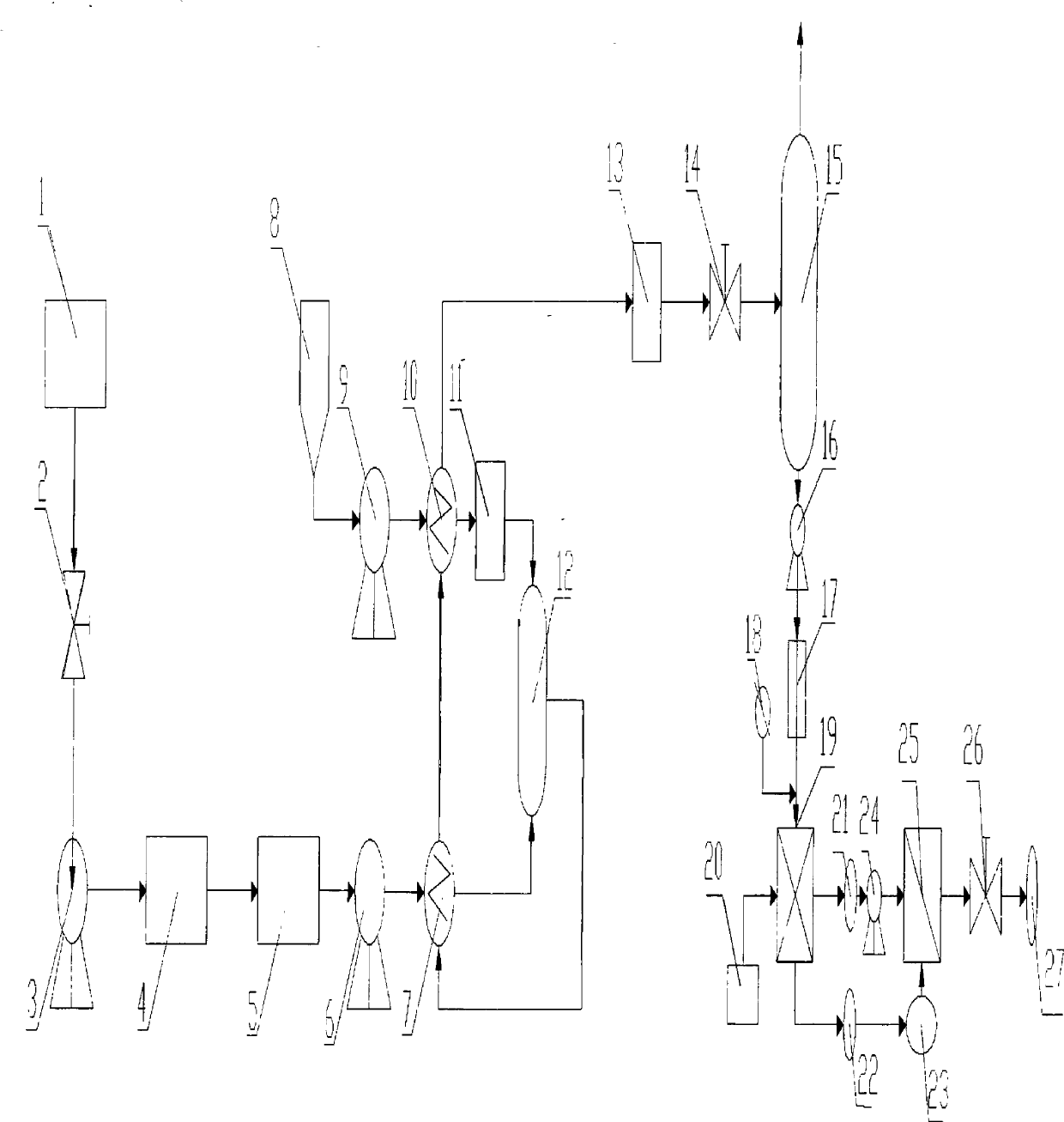

[0026] A method for co-processing waste water discharged from Tianjin Goubuli Food Co., Ltd. by supercritical water oxidation and membrane separation, the steps are:

[0027] The waste water first passes through the grid well to remove large particles such as vegetable leaves and small pieces of meat, and then enters the regulating sedimentation filter. After coming out, it is pressurized to 34MPa by a high-pressure pump and input to the heat exchanger 7 for preheating. After the waste water is preheated to 280°C, it flows into the Supercritical water oxidation reactor; at the same time, the oxidant is pressurized from the storage tank 8 to 34MPa by the high-pressure pump 9 and input into the heat exchanger 10 for preheating, and the oxidant and waste water heated by the heater 11 at 340°C are respectively sent to the supercritical water oxidation reactor The two ends of 8 flow in to carry out the supercritical water oxidation reaction. The fluid after the reaction is exchange...

Embodiment 2

[0029] The method for supercritical water oxidation and membrane separation to jointly treat wastewater discharged from a biscuit processing plant, the steps are:

[0030] The waste water first passes through the grid well to remove large particles such as vegetable leaves and small pieces of meat, and then enters the regulating sedimentation filter. After coming out, it is pressurized to 32MPa by a high-pressure pump and input to the heat exchanger 7 for preheating. After the waste water is preheated to 250°C, it flows into the Supercritical water oxidation reactor; at the same time, the oxidant is pressurized from the storage tank 8 to 32MPa by the high-pressure pump 9 and input into the heat exchanger 10 for preheating, and the oxidant and waste water heated by the heater 11 at 320°C are respectively sent to the supercritical water oxidation reactor The two ends of 8 flow in to carry out the supercritical water oxidation reaction. The fluid after the reaction is exchanged h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com