Preparation method of molybdenum-based material surface protection coating

A protective coating and molybdenum-based technology, which is applied in the coating process and coating of metal materials, can solve the problems of slow deposition rate of powder embedding method, limit the application range of embedding method, and low utilization rate of raw materials, etc., and achieve good Oxidation resistance, easy slurry composition, and production cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

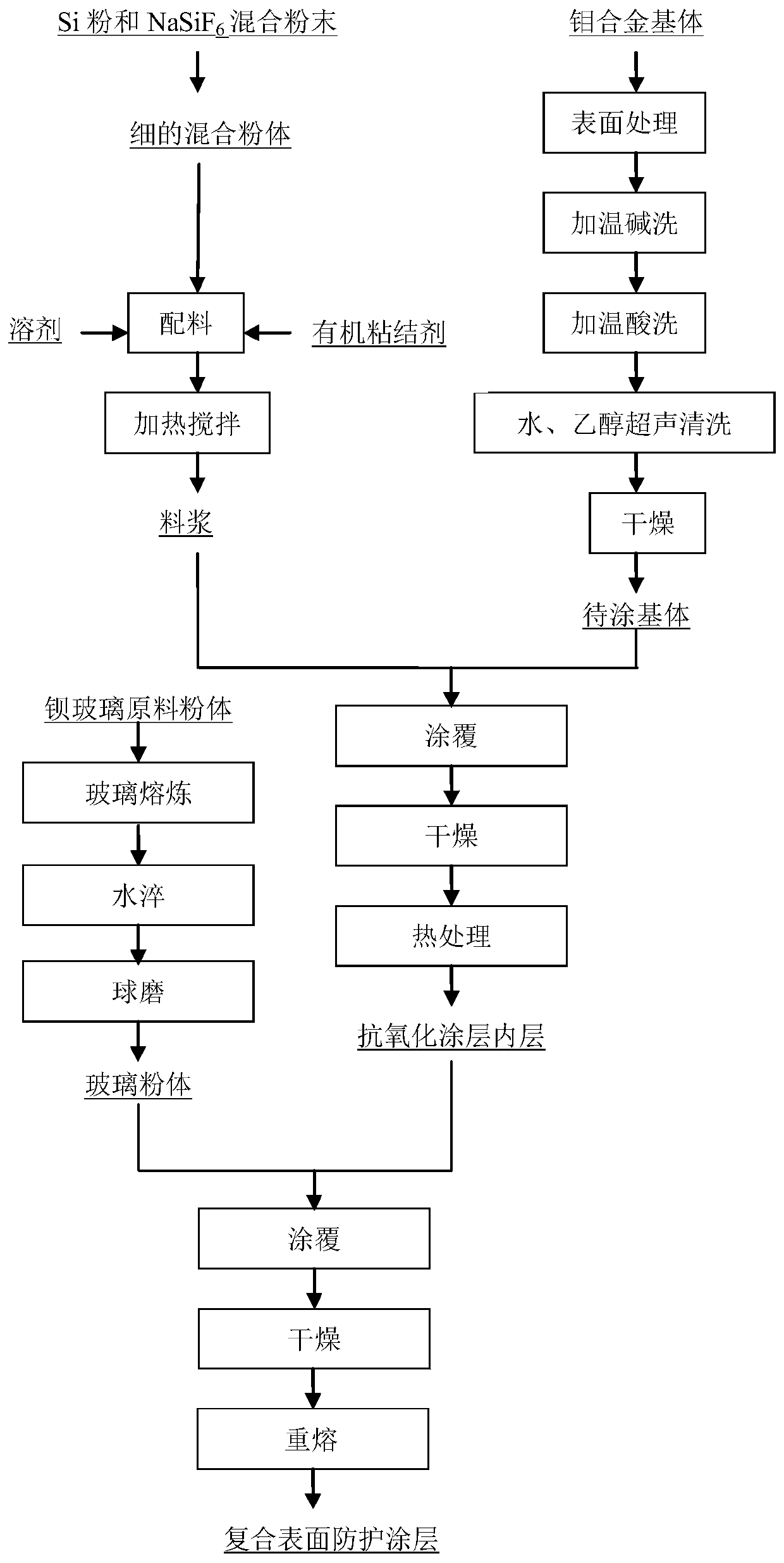

[0026] The preparation method of the molybdenum-based material surface protective coating of the present invention includes the following steps: coating the siliconized slurry on the surface of the molybdenum-based material, drying it, placing it in a protective atmosphere, and heat preservation treatment at a temperature of 600-1300°C to form a siliconized coating. Silicon layer, to get final product; the siliconized slurry is mainly composed of Si powder, Na 2 SiF 6 , organic binder and solvent composition, the Si powder and Na 2 SiF 6 The mass ratio of the organic binder is (1~19):1, and the quality of the organic binder is Si powder and Na 2 SiF 6 0.1-3% of the total mass, Si powder and Na 2 SiF 6 The ratio of the total mass to the volume of the solvent is (1-5) g: 1 mL. The temperature of the drying treatment is 80-150°C. The drying time is 1.5-6 hours.

[0027] Preferably, the organic binder is ethyl cellulose, and the solvent is one of terpineol, toluene, xylene...

Embodiment 1

[0043] The preparation method of the molybdenum-based material surface protective coating of the present embodiment, its flow process is as follows figure 1 As shown, it specifically includes the following steps:

[0044] (1) Substrate pretreatment: TZM alloy plates (20mm×15mm×1mm) are firstly polished with 280# and 400# sandpaper to remove surface stains, and then washed in 4wt% NaOH aqueous solution at 75°C for 10min and 10vt% HCl aqueous solution was pickled in a 75°C water bath for 2 minutes to remove oil stains, and finally ultrasonically cleaned with distilled water and ethanol, and then dried in a 70°C drying oven to obtain alloy samples;

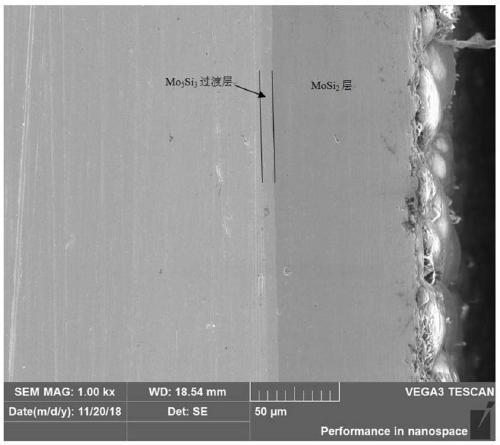

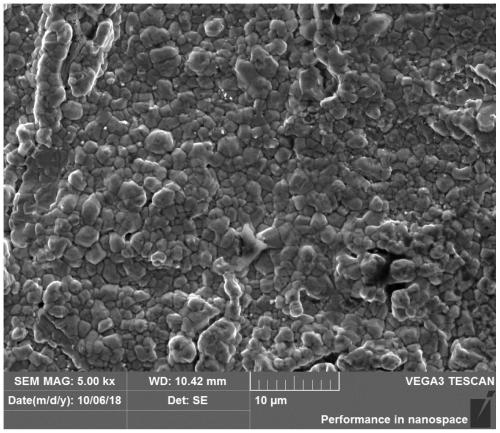

[0045] (2) Slurry preparation and coating: 50g Si powder (average particle size 35μm), 50g Na 2 SiF 6 Mix the powder evenly, add 0.1g ethyl cellulose and 100mL terpineol, stir magnetically in a water bath at 85°C for 2 hours to obtain a slurry, and coat the slurry evenly on the surface of the alloy sample with a coating thickness o...

Embodiment 2

[0050] The preparation method of the molybdenum-based material surface protective coating of the present embodiment comprises the following steps:

[0051] (1) Substrate pretreatment: TZM alloy plates (20mm×15mm×1mm) are firstly polished with 280# and 400# sandpaper to remove surface stains, and then washed in 4wt% NaOH aqueous solution at 60°C for 15min and 10vt% HCl aqueous solution was pickled in 80°C water bath for 10 minutes to remove oil stains, and finally ultrasonically cleaned with distilled water and ethanol, and then dried in a 60°C drying oven to obtain alloy samples;

[0052] (2) Slurry preparation and coating: 60g Si powder (average particle size 30μm), 40g Na 2 SiF 6 Mix the powder evenly, add 0.5g ethyl cellulose and 80mL terpineol, stir magnetically in a water bath at 60°C for 4 hours to obtain a slurry, and coat the slurry evenly on the surface of the alloy sample with a coating thickness of 1000μm; then place Dry in a drying oven at 130°C for 3 hours to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com