Method for treating industrial wastewater through subcritical water oxidation process in combination with biochemical process

A subcritical water and industrial wastewater technology, applied in the direction of oxidation water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problem of severe acid corrosion of equipment, and achieve corrosion reduction, huge social and economic benefits Efficiency, ease of large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Present embodiment industrial wastewater treatment process is as follows:

[0025] (1) Subcritical water oxidation pretreatment:

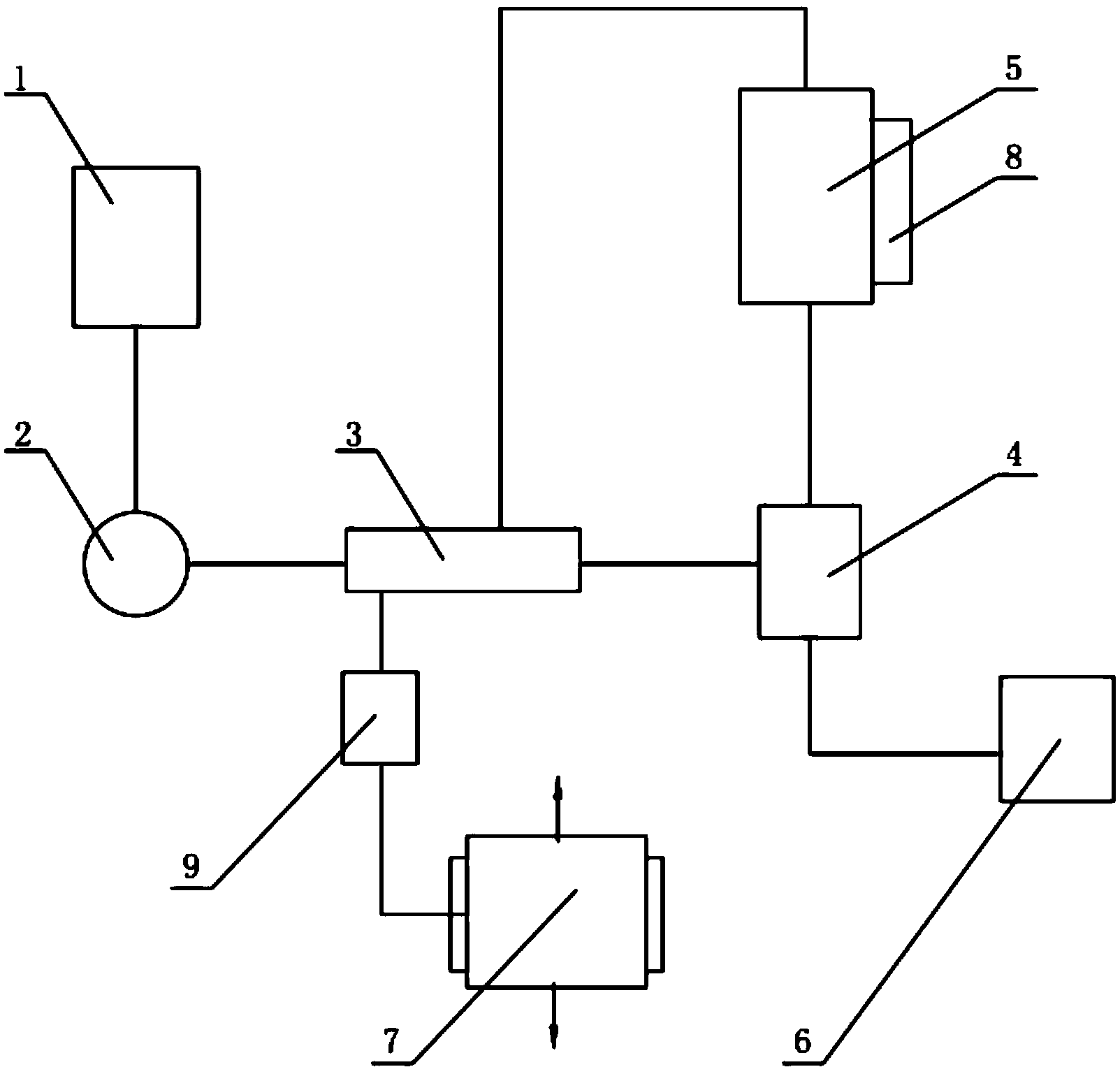

[0026] The industrial wastewater is pumped out from the wastewater storage tank 1, filtered and pressurized by the booster pump 2, then preheated by the heat exchanger 3, flows into the mixer 4 and mixed with the oxygen provided by the air compressor 6, and enters the titanium stainless steel reactor 5 to generate In the subcritical water oxidation reaction, the pressure in the reactor 5 is controlled to 5 MPa and the temperature is 240°C through the heater 8 to degrade the toxic organic substances in the wastewater; the reacted fluid is exchanged by the heat exchanger 3 for preheating The waste water transported into the heat exchanger 5 is cooled by the cooler 9, and the pressure is lowered to 0 MPa, and then enters the gas-liquid separator 7, and the obtained liquid-phase water and gas-phase gas products are discharged from the bottom and...

Embodiment 2

[0029] (1) Subcritical water oxidation pretreatment:

[0030] The industrial wastewater is pumped out from the wastewater storage tank 1, filtered and pressurized by the booster pump 2, then preheated by the heat exchanger 3, flows into the mixer 4 and mixed with the oxygen provided by the air compressor 6, and enters the titanium stainless steel reactor 5 to generate In the subcritical water oxidation reaction, the pressure in the reactor 5 is controlled by the heater 8 to 8 MPa and the temperature is 180°C to degrade the toxic organic matter in the wastewater; the reacted fluid is exchanged by the heat exchanger 3 for preheating The waste water transported into the heat exchanger 5 is cooled by the cooler 9, and the pressure is lowered to 0 MPa, and then enters the gas-liquid separator 7, and the obtained liquid-phase water and gas-phase gas products are discharged from the bottom and top of the separator respectively; Inorganic salts in the critical water oxidation state ar...

Embodiment 3

[0033] (1) Subcritical water oxidation pretreatment:

[0034] The industrial wastewater is pumped out from the wastewater storage tank 1, filtered and pressurized by the booster pump 2, then preheated by the heat exchanger 3, flows into the mixer 4 and mixed with the oxygen provided by the air compressor 6, and enters the titanium stainless steel reactor 5 to generate In the subcritical water oxidation reaction, the pressure in the reactor 5 is controlled to 12MPa and the temperature is 150°C through the heater 8 to degrade the toxic organic substances in the wastewater; the reacted fluid is exchanged by the heat exchanger 3 for preheating The waste water transported into the heat exchanger 5 is cooled by the cooler 9, and the pressure is lowered to 0 MPa, and then enters the gas-liquid separator 7, and the obtained liquid-phase water and gas-phase gas products are discharged from the bottom and top of the separator respectively; Inorganic salts in the critical water oxidation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com