Method for actuating a spark gap

A technology of spark gap and spark plug, applied in the field of spark gap, can solve problems such as difficult stable state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] In addition to spark plugs, the following description applies to spark gaps accordingly.

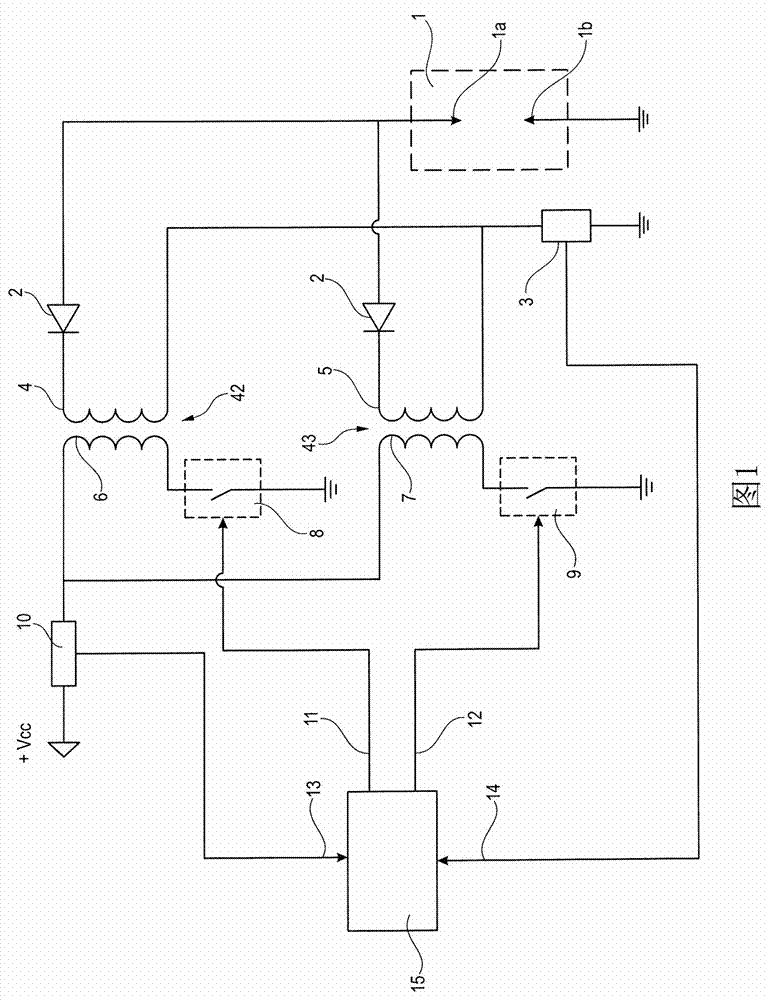

[0119] figure 1 The circuit arrangement illustrated in has a spark gap 1 , for example a spark plug, with a center electrode 1 a and a ground electrode 1 b. There are two ignition coils 42 and 43 to provide the necessary high voltage for the spark plug 1 . Ignition coil 42 has a primary winding 6 and a secondary winding 4 inductively coupled to primary winding 6 . The ignition coil 43 has a primary winding 7 and a secondary winding 5 which is inductively coupled to the primary winding 7 . For the sake of simplicity, the magnetic core coupling the primary winding 6 and the secondary winding 4 and the magnetic core coupling the primary winding 7 and the secondary winding 5 are not shown in the figure. The secondary winding 4 is located together with the spark plug 1 in the first secondary circuit. The secondary winding 5 is arranged together with the spark plug 1 in the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com