Low-temperature fluid delivery tube connector with potential isolating function

A technology for cryogenic fluids and conveying pipes, applied to pipes/pipe joints/fittings, heat insulation protection pipes, heat preservation, etc., can solve the problems of ineffective isolation of high and low potentials, achieve simple structure, convenient installation, and ensure heat insulation requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

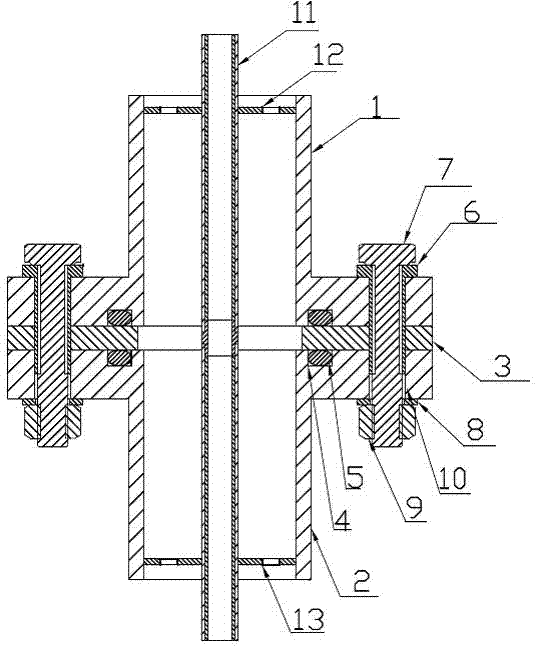

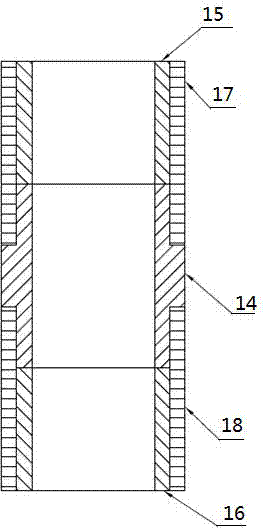

[0017] A double-layer low-temperature fluid delivery pipe joint with potential isolation function, including such as figure 1 External piping as shown, such as figure 2 Internal piping shown.

[0018] Such as figure 1 , the external pipeline is composed of upper flange 1, lower flange 2 and epoxy spacer 3. Both the upper flange 1 and the lower flange 2 are provided with a sealing groove 4, and a circular section sealing ring 5 is placed in the sealing groove 4, and an epoxy sleeve 6 is placed in the bolt hole 10 of the flange, and the lower surface of the lower flange 2 Place epoxy gasket 8 and fasten it with bolt 7 and nut 9.

[0019] The material resistivity of the epoxy spacer 3 is very high, which can separate the potential of the upper flange 1 and the lower flange 2 . The upper and lower surfaces of the epoxy spacer 3 are smooth, and used together with the sealing ring 5 in the sealing groove 4, the vacuum in the tube can be guaranteed. The epoxy sleeve 6 ensures t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com