Separated type solar water heater provided with U-shaped tube heat collector and enamel outer interlayer heat exchanger

A heat collector and heat exchanger technology, applied in the field of solar water heaters, can solve the problems of low thermal efficiency, fatigue crack leakage, insufficient heat collection efficiency, etc., and achieve the effects of improving heat exchange efficiency, improving service life, and accelerating cycle speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing:

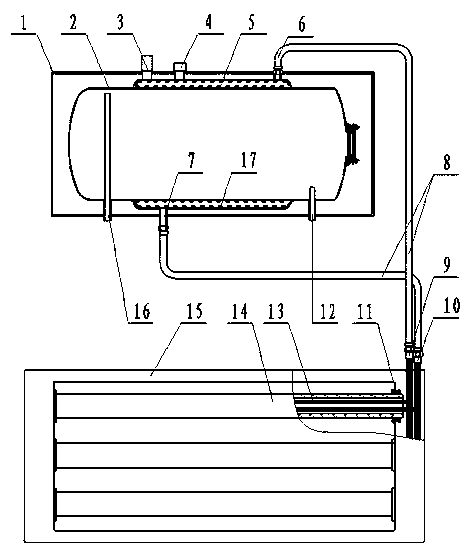

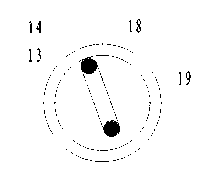

[0014] Such as figure 1 , figure 2 As shown, the present invention relates to a split solar energy with a U-shaped tube heat collector and an enamel outer sandwich heat exchanger, including a water tank and a heat collector, and an inner tank 2 is installed in the water tank 1, and the inner tank 2 is composed of a sandwich inner tank 17 An enamel interlayer heat exchanger 5, the outer end of the heat exchanger 5 is respectively provided with an exhaust pipe 3, a liquid injection port 4, a medium circulation inlet 6 and a medium circulation outlet 7, and the medium circulation inlet 6 and the medium circulation outlet 7 respectively pass through the water tank 1. The outer wall is connected with the medium circulation pipe 8. The liner 2 is provided with a water inlet pipe 12 and a water outlet pipe 16, and the water inlet pipe 12 and the water outlet pipe 16 pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com