Chip stack structure and method for fabricating the same

A technology of chip stacking and manufacturing method, applied in the fields of semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve the problems affecting the overall product reliability, high structural residual stress, affecting the processing yield, etc., to shorten the processing time. Time, reduced processing cost, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

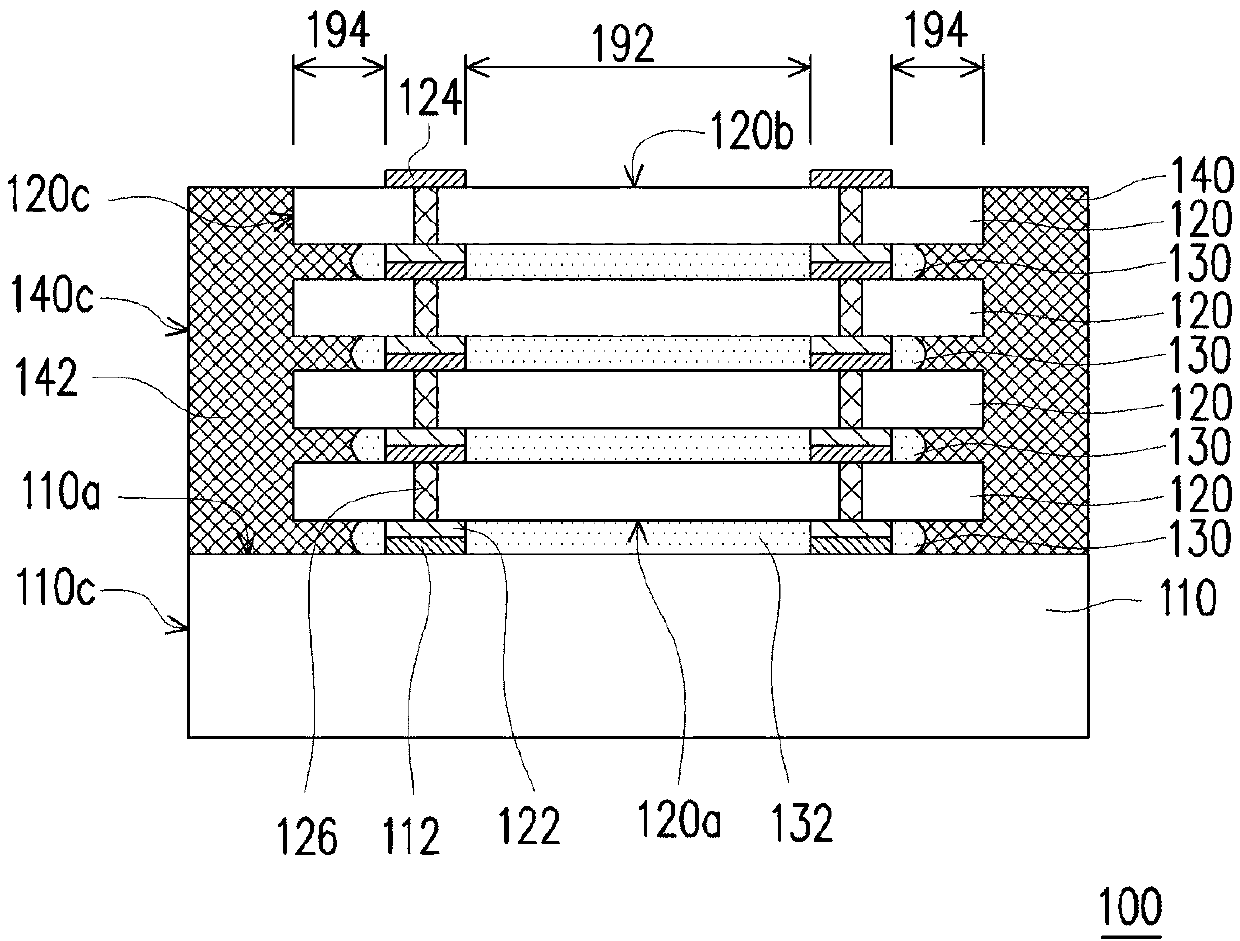

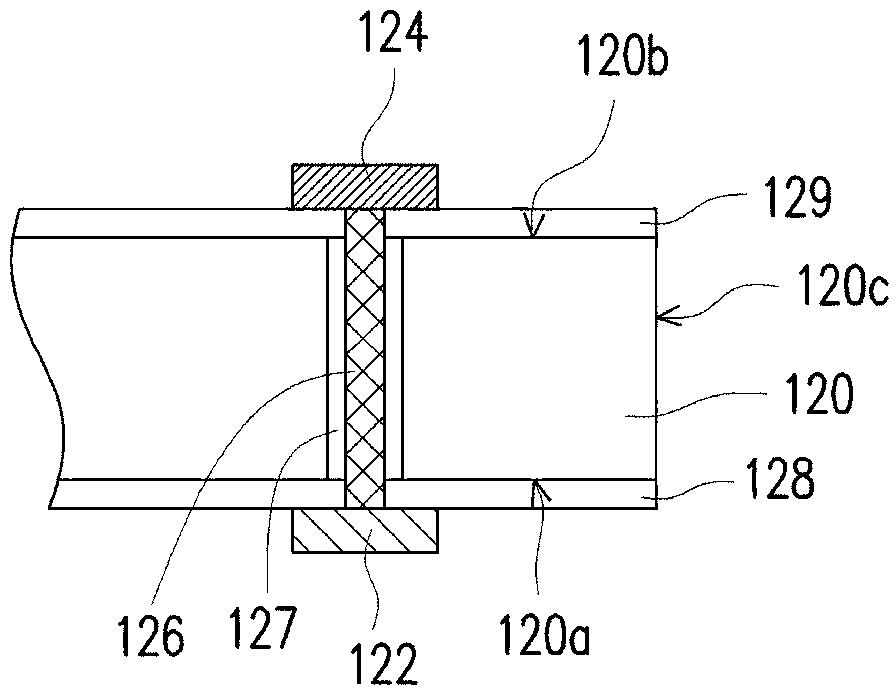

[0110] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0111] Figure 1A It is a chip stack structure according to an embodiment of the present invention. The chip stacking structure 100 of this embodiment is directly stacking chips on a large wafer, and the formed structure includes a first chip 110 as a stacking base, and one or more second chips 120 stacked on the first chip 110, The thickness of the first chip 110 is greater than 100 microns (μm), which can provide good support during processing. In addition, the size of the first chip 110 is, for example, larger than the size of the second chip 120 , wherein the size refers to parameters such as thickness, length, width, and area of the chip.

[0112] This embodiment is a case of stacking a plurality of second chips 120 , however, the number of second chips 120 can be changed according to actual needs, and is not limited t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com