Mixed gas production device

A technology of mixing gas and manufacturing equipment, which is applied in the direction of mixers, fluid mixers, gas fuel burners, etc., can solve the problem of high cost, and achieve the effect of noise reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

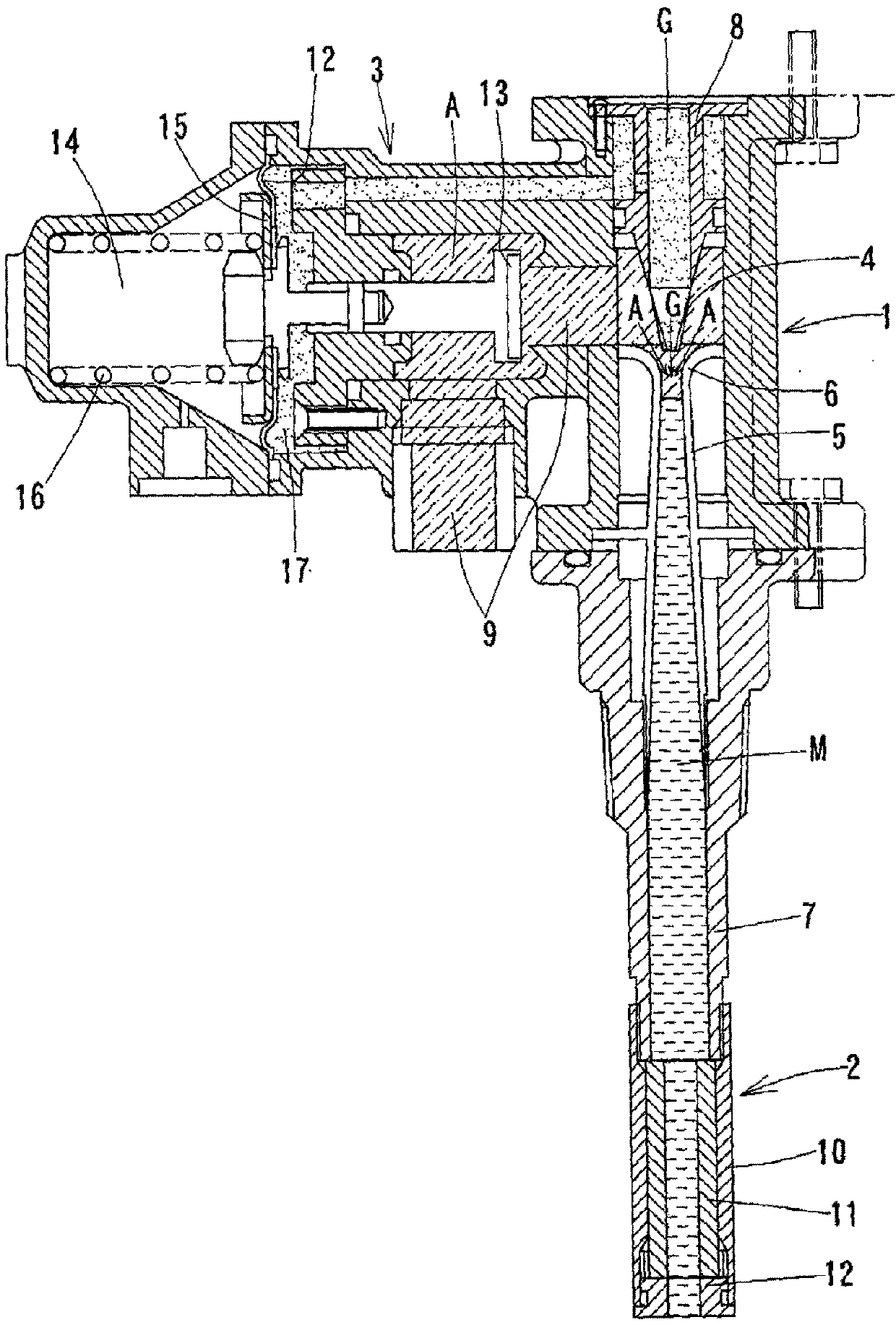

[0022] figure 1 A mixed gas production apparatus with a noise reduction device according to the present invention is shown. This apparatus is used when the raw material gas G and the combustion air A are mixed to produce the mixed gas M that matches the fuel calorific value of the city gas (12A, 13A, etc.) normally used by the user.

[0023] The apparatus is provided with: a venturi mixer 1 which mixes the raw material gas G with combustion air A; a noise reduction device 2 which reduces noise generated in the venturi mixer 1; and an air valve 3 which corresponds to the The supply pressure roughly adjusts the supply amount of the combustion air A.

[0024] The venturi mixer 1 includes a nozzle 4 for injecting the raw material gas G, and a narrow channel 5 that is coaxial with the nozzle 4 and is arranged slightly apart. The narrow passage 5 forms a constricted portion 6 in the vicinity of the inlet, and is formed in a conical shape whose inner diameter increases toward the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com