Okra extracting solution, okra extractives, preparation methods therefor, and applications therefor

An extract and extract technology, applied in the field of okra extract, can solve problems such as skin irritation, harm to health, pigmentation, etc., and achieve the effect of lightening spots, easy operation, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

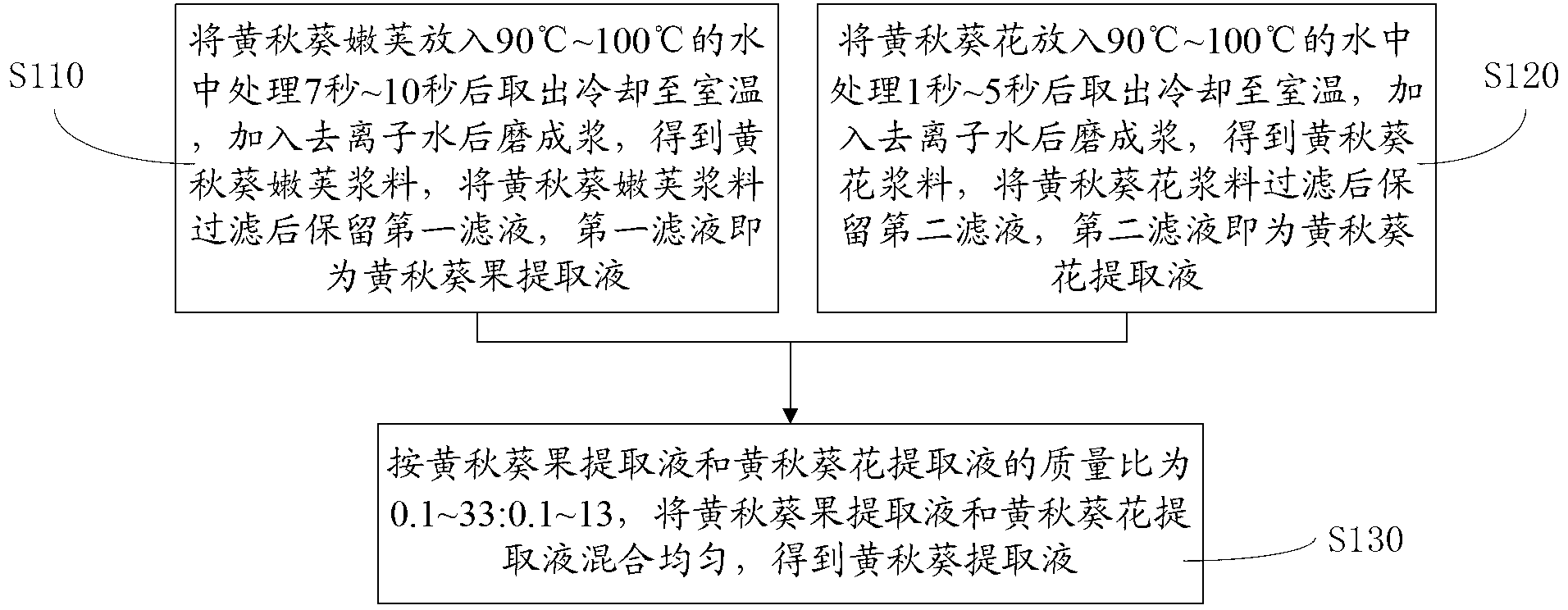

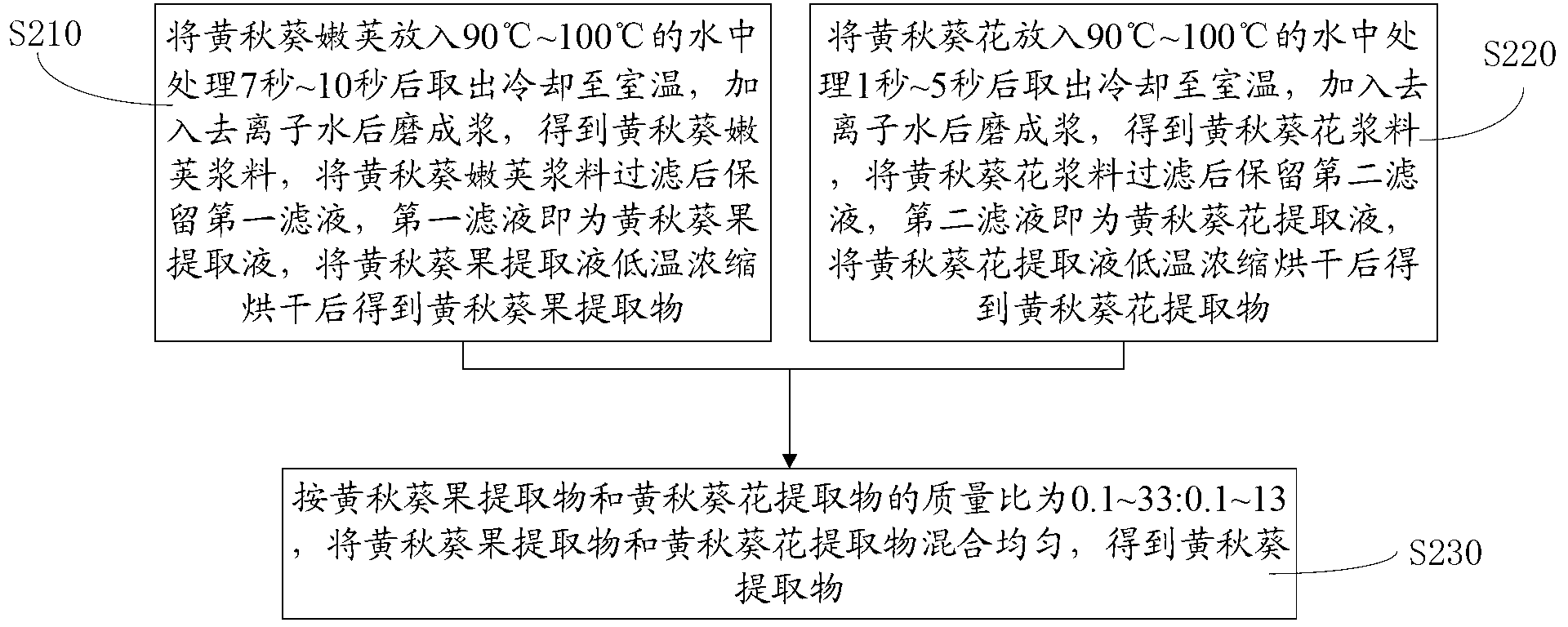

[0039] Such as figure 1 Shown, the preparation method of the okra extract of one embodiment comprises the following steps:

[0040] S110. Put the young okra pods into water at 90° C. to 100° C. and treat them for 7 seconds to 10 seconds, take them out and cool them to room temperature, add deionized water and grind them into a slurry to obtain the okra tender pods slurry, and filter the okra tender pods slurry Afterwards, the first filtrate is reserved, and the first filtrate is the okra fruit extract.

[0041] In S110, young okra pods do not contain impurities and spoiled young okra pods. The tender pods of okra are 3-5 days old okra fruit pods. Among them, the tender pods of okra with a length of 8 cm to 10 cm are of better quality. The young okra pods are treated in water at 90°C to 100°C to have the effect of degerming. The mass ratio of the deionized water to the young okra pods can be 2-3:7-8.

[0042]In S110, the operation of retaining the first filtrate after filt...

Embodiment 1

[0113] The young okra pods were put into 100° C. water for 7 seconds, taken out and cooled to room temperature, deionized water was added and ground into a slurry to obtain the young okra pods slurry. Wherein, the mass ratio of deionized water to young okra pods is 2:7.

[0114] After filtering the okra tender pod slurry with a 45-mesh filter screen, let it stand for 24 hours, then continue to filter with a 90-mesh filter screen and retain the first filtrate, which is the okra fruit extract.

[0115] Put the okra flower into 100°C water for 5 seconds, take it out and cool it to room temperature, add deionized water and grind it into a slurry to obtain the okra flower slurry. Wherein, the mass ratio of deionized water and okra flower is 2:7.

[0116] The okra flower slurry was filtered with a 45-mesh filter and left to stand for 24 hours, and then continued to filter with a 90-mesh filter and the second filtrate was retained, and the second filtrate was the okra flower extract...

Embodiment 2

[0119] The young okra pods were put into 90° C. water for 10 seconds, taken out and cooled to room temperature, deionized water was added and ground into a slurry to obtain the young okra pods slurry. Wherein, the mass ratio of deionized water to young okra pods is 3:8.

[0120] After filtering the okra tender pod slurry with a 40-mesh filter screen, let it stand for 48 hours, then continue to filter with a 100-mesh filter screen and retain the first filtrate, which is the okra fruit extract.

[0121] Put the okra flowers into water at 95° C. for 1 second, take them out and cool to room temperature, add deionized water and grind them into a slurry to obtain the okra flower slurry. Wherein, the mass ratio of deionized water and okra flower is 3:8.

[0122] After filtering the okra flower slurry with a 40-mesh filter screen, let it stand for 24 hours, then continue to filter with an 80-mesh filter screen and retain the second filtrate, which is the okra flower extract.

[0123...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com