Non-sticky and non-greasy cosmetic and edible aloe gel from normal juice and preparation method of aloe gel

A technology of aloe vera gel and aloe vera gel juice, which is applied in the field of maintenance daily chemicals, and can solve problems such as sticking to the skin, compatibility problems, and aloe vera gel material problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

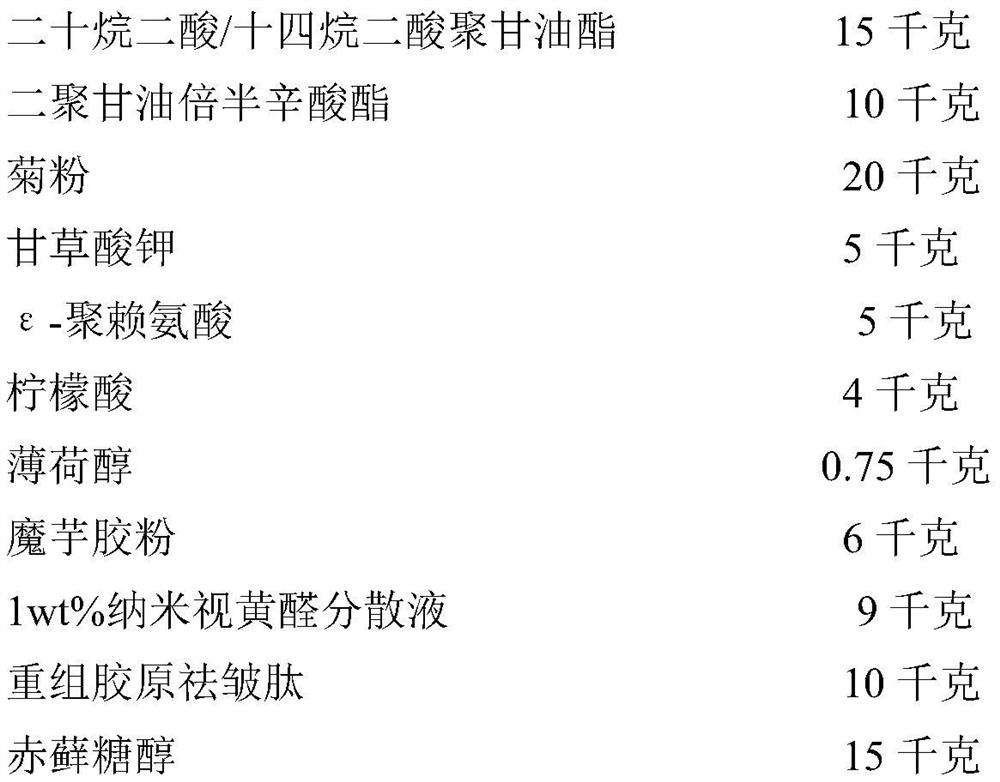

Embodiment 1

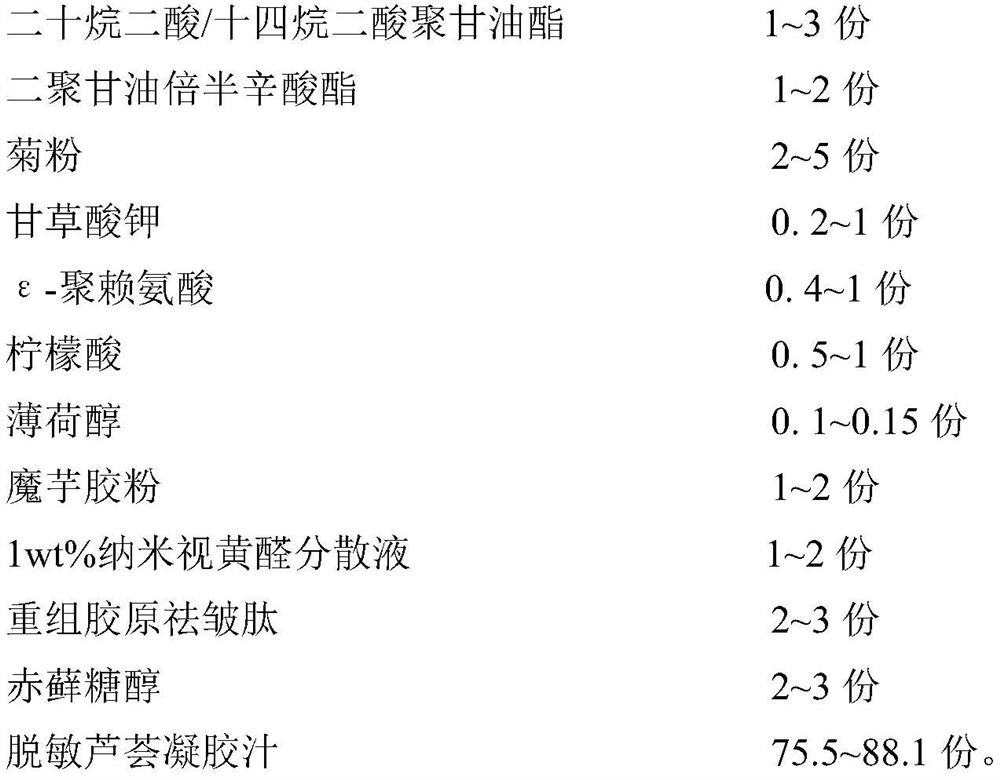

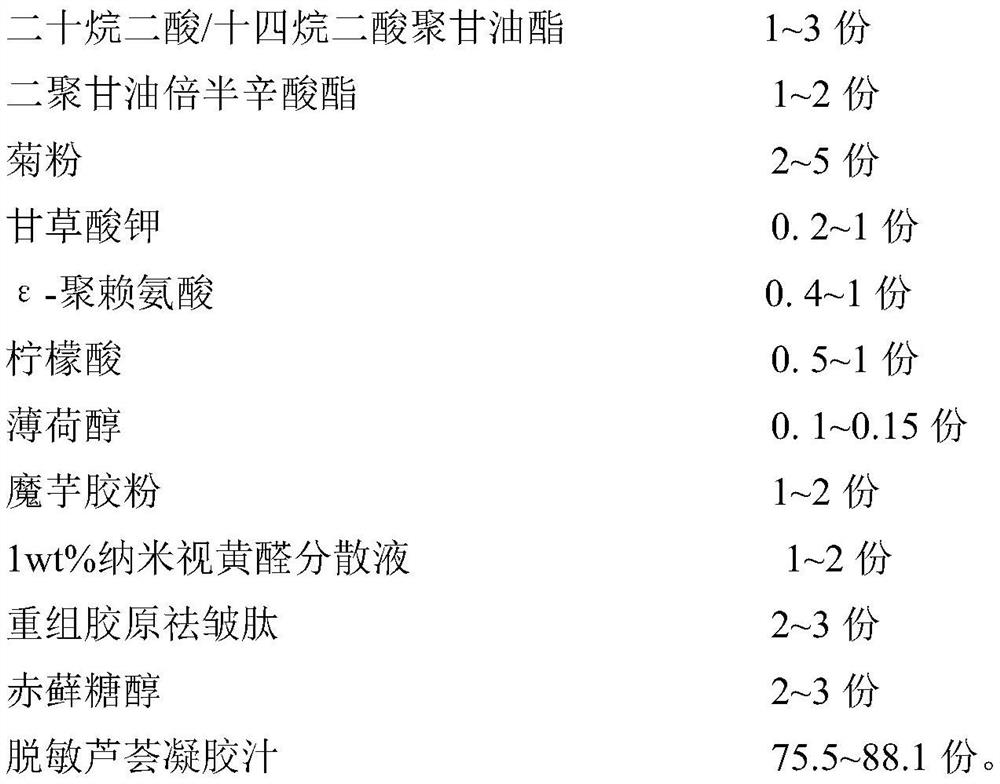

[0062]

[0063]

[0064] (1) Pre-batching process:

[0065] In a 200-liter high-quality stainless steel batching pot, under stirring conditions, the rotational speed is controlled at 100 rpm, 5 kg of potassium glycyrrhizinate is put into 55.03 kg of aloe juice, the temperature is raised to 55 ° C, and the system is dissolved for 0.6 hours until the system is completely transparent to obtain material A;

[0066] In a 100 liter high-quality stainless steel batching pot, under the condition of stirring, the speed is controlled at 100 rpm, 4 kg of citric acid is put into 55.03 kg of aloe juice, the temperature is raised to 52 ° C, and the system is completely transparent after dissolving for 0.5 hours to obtain material B;

[0067] In a 100-liter high-quality stainless steel batching pot, under stirring conditions, control the speed at 100 rpm, put 5 kg of ε-polylysine into 55.03 kg of aloe juice, heat up to 72 ° C, dissolve for 0.5 hours until the system is completely transp...

Embodiment 2

[0076]

[0077]

[0078] (1) Pre-batching process:

[0079] In a 200 liter high-quality stainless steel batching pot, under the condition of stirring, the speed is controlled at 100 rpm, 1 kg of potassium glycyrrhizinate is put into 55.2 kg of aloe juice, the temperature is raised to 55 ° C, and the system is dissolved for 0.5 hours until the system is completely transparent to obtain material A;

[0080] In a 100 liter high-quality stainless steel batching pot, under the condition of stirring, control the speed of 100rpm, put 3 kg of citric acid into 55.2 kg of aloe juice, heat up to 52 ° C, dissolve for 0.8 hours until the system is completely transparent, and obtain material B;

[0081] In a 100-liter high-quality stainless steel batching pot, under stirring conditions, control the speed at 100 rpm, put 2 kg of ε-polylysine into 55.2 kg of aloe juice, heat up to 72 ° C, dissolve for 0.6 hours until the system is completely transparent, cool to 45 ℃, get material C;

...

Embodiment 3

[0090]

[0091]

[0092] (1) Pre-batching process:

[0093] In a 200 liter high-quality stainless steel batching pot, under the condition of stirring, control the speed of 100rpm, put 2 kg of potassium glycyrrhizinate into 49.8 kg of aloe juice, heat up to 50 ° C, dissolve for 0.8 hours until the system is completely transparent, and obtain material A;

[0094] In a 100 liter high-quality stainless steel batching pot, under stirring conditions, the speed is controlled at 100 rpm, 5 kg of citric acid is put into 49.8 kg of aloe juice, the temperature is raised to 55 ° C, and the system is dissolved for 0.8 hours until the system is completely transparent to obtain material B;

[0095] In a 100 liter high-quality stainless steel batching pot, under stirring conditions, control the speed of 100rpm, put 4 kg of ε-polylysine into 49.8 kg of aloe juice, heat up to 78 ° C, dissolve for 0.8 hours until the system is completely transparent, cool to 42 ℃, get material C;

[0096]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com