Nano-silver colloidal solution, preparation method for nano-silver colloidal solution and application of nano-silver colloidal solution

A colloidal solution and nano-silver technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of textile finishing agents that have not been reported, and achieve excellent anti-mite effect, good stability, and the effect of expanding efficacy and application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Take 3-phenylchlorobenzyl (IRS) cis, trans-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropane carboxylate 3g, dissolve in 100mL deionized In water, 3-phenylchlorobenzyl (IRS) cis, trans-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropanecarboxylic acid with a mass volume concentration of 30g / L was obtained Aqueous solution of ester;

[0022] 2. Dissolve 0.787g of silver nitrate in 100mL of aqueous solution to obtain a silver nitrate solution with a mass volume concentration of 7.87g / L;

[0023] 3. Dissolve 0.1 g of sodium borohydride in 100 mL of aqueous solution to obtain a sodium borohydride solution with a mass volume concentration of 1 g / L;

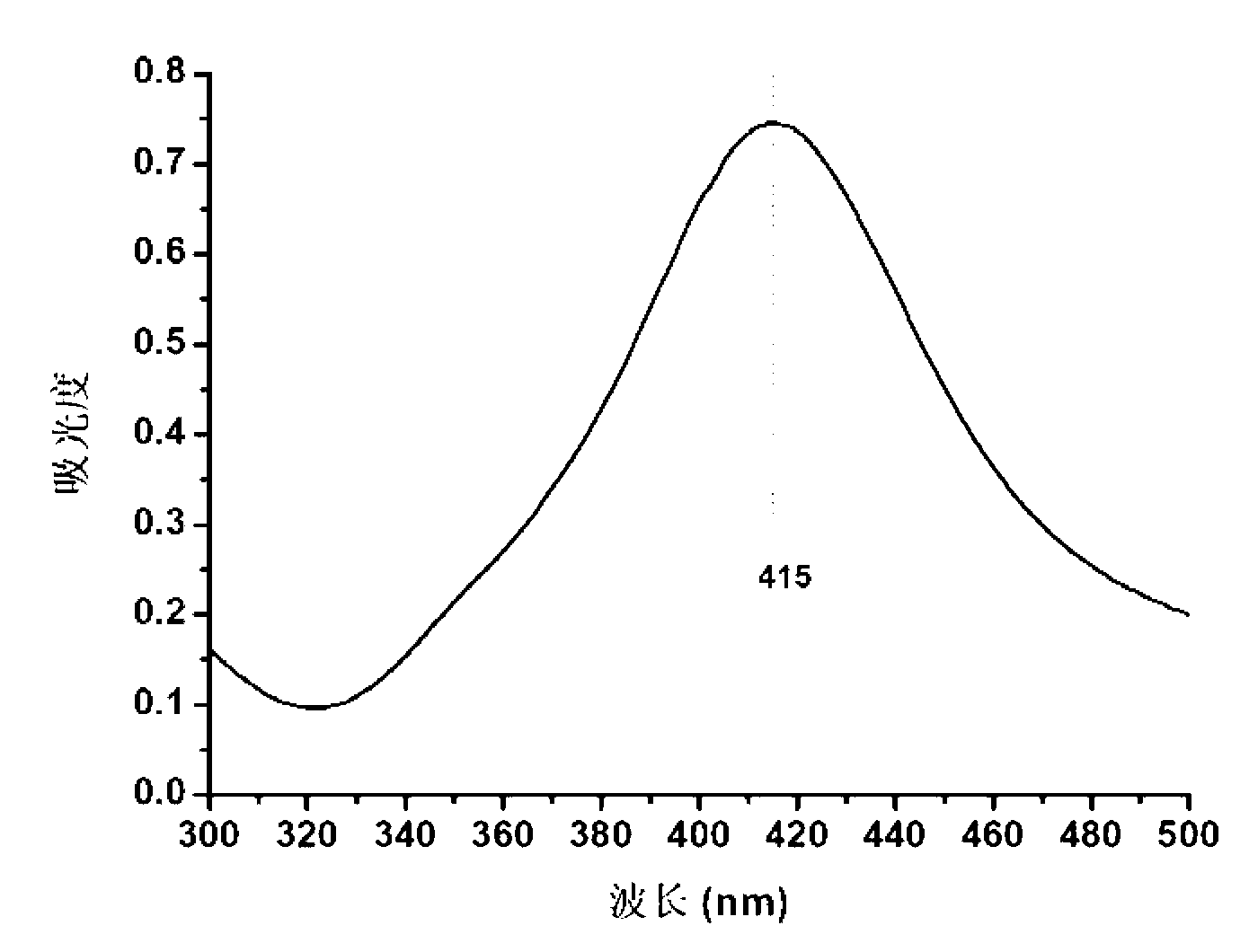

[0024] 4. Mix 30g / L 3-phenylchlorobenzyl (IRS) cis, trans-3-(2,2-dichlorovinyl)-2,2-dimethylcyclopropane carboxylate aqueous solution and Silver nitrate solution with a mass volume concentration of 7.87g / L is mixed at a volume ratio of 4:1, and sodium borohydride solution is added dropwise under constant stirring at 70°C until the...

Embodiment 2

[0030] 1. Dissolve 3 g of dimethylcyclopropane carboxylate in 100 mL of deionized water to obtain an aqueous solution of dimethyl cyclopropane carboxylate with a mass volume concentration of 30 g / L;

[0031] 2. Dissolve 0.787g of silver nitrate in 100mL of aqueous solution to obtain a silver nitrate solution with a mass volume concentration of 7.87g / L;

[0032] 3. Dissolve 0.1 g of sodium borohydride in 100 mL of aqueous solution to obtain a sodium borohydride solution with a mass volume concentration of 1 g / L;

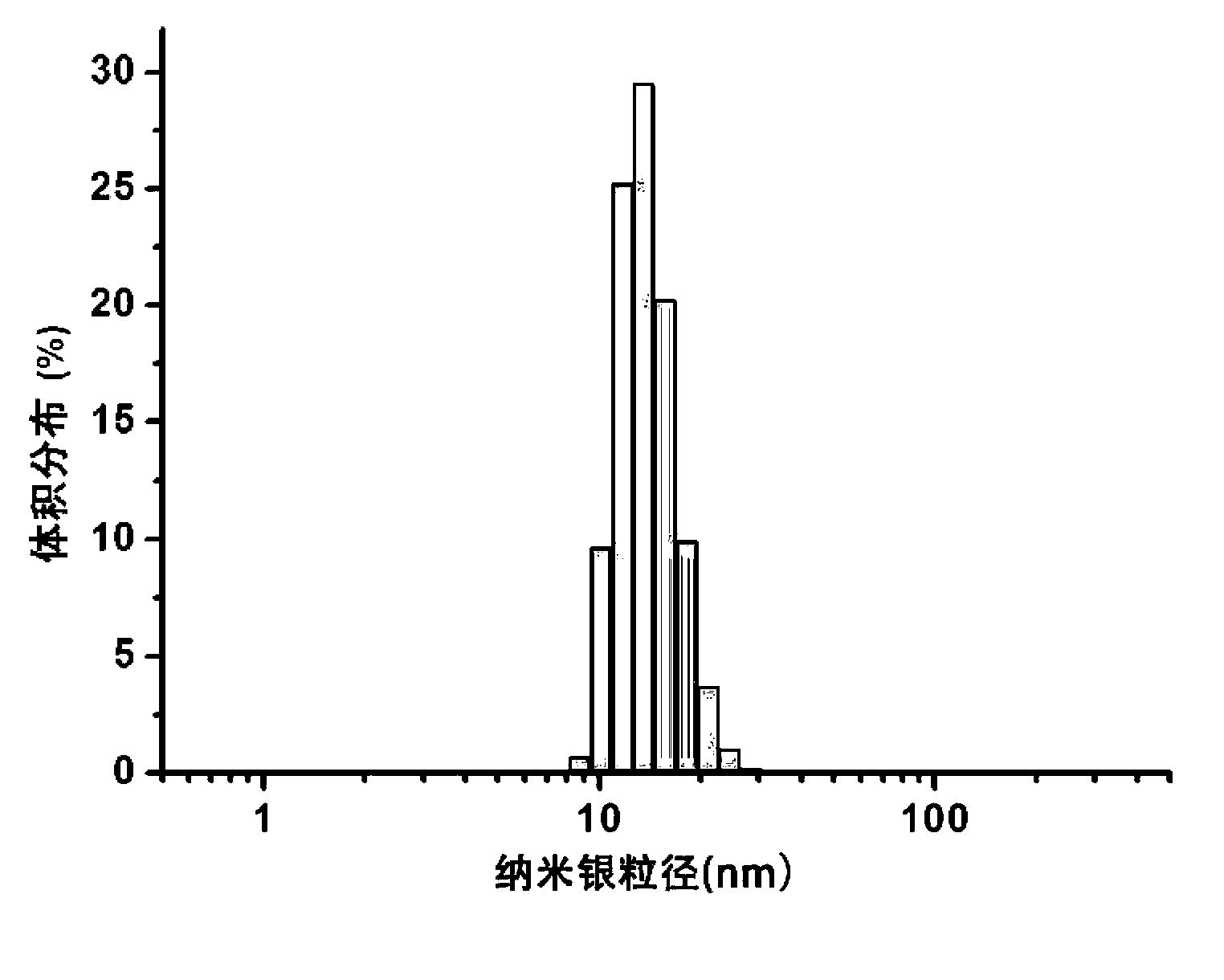

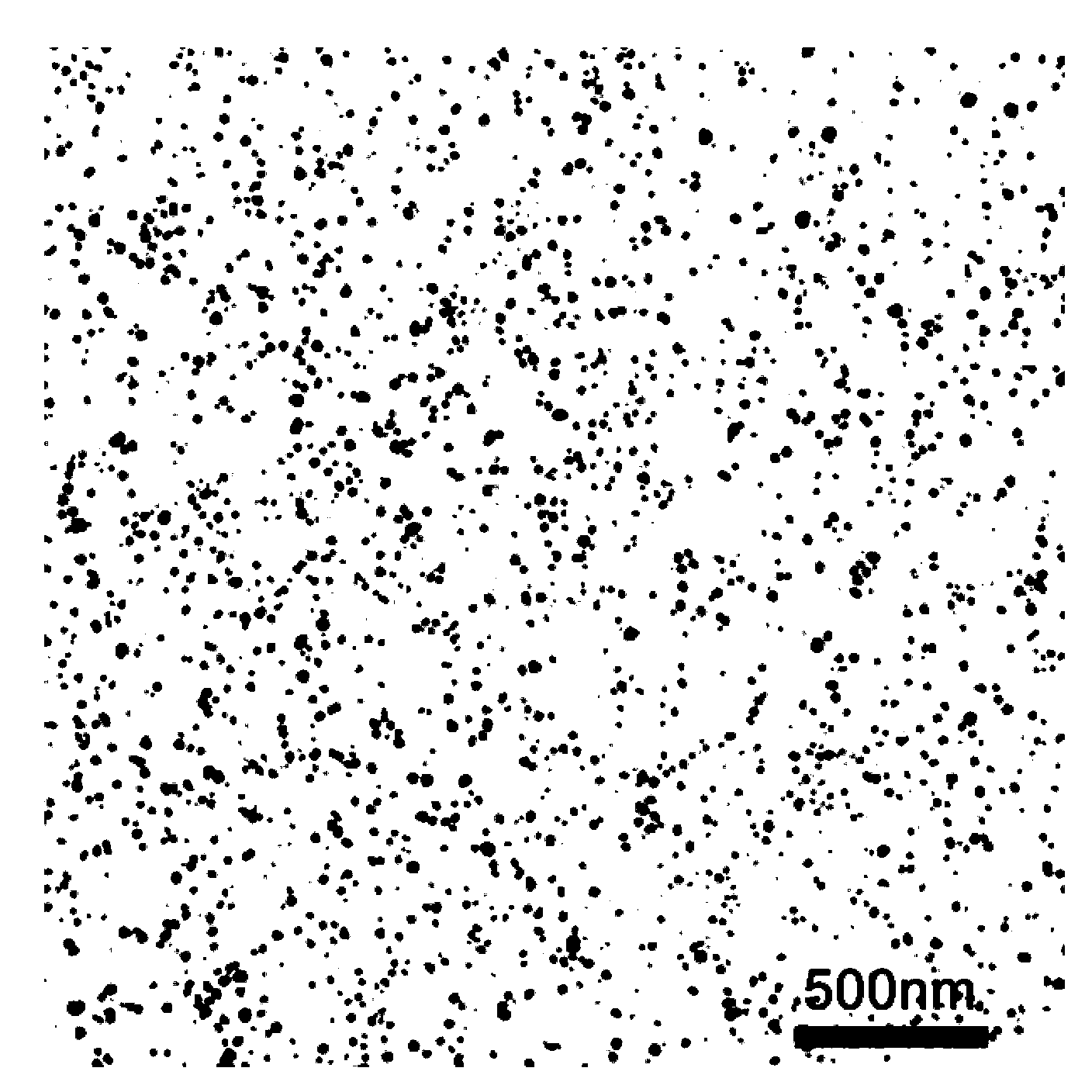

[0033] 4. Mix 30g / L aqueous solution of dimethylcyclopropane carboxylate and 7.87g / L silver nitrate solution at a volume ratio of 4:1, add sodium borohydride solution dropwise under constant stirring at 70°C until the reaction is complete , the nano-silver colloidal solution with a particle size of 10-40nm can be obtained.

Embodiment 3

[0035] 1. Dissolve 5 g of dimethylcyclopropane carboxylate in 100 mL of deionized water to obtain an aqueous solution of dimethyl cyclopropane carboxylate with a mass volume concentration of 50 g / L;

[0036] 2. Dissolve 0.787g of silver nitrate in 100mL of aqueous solution to obtain a silver nitrate solution with a mass volume concentration of 7.87g / L;

[0037] 3. Dissolve 0.1 g of sodium borohydride in 100 mL of aqueous solution to obtain a sodium borohydride solution with a mass volume concentration of 1 g / L;

[0038] 4. Mix 50g / L dimethylcyclopropane carboxylate aqueous solution and 7.87g / L silver nitrate solution at a volume ratio of 4:1, add sodium borohydride solution dropwise under constant stirring at 70°C until the reaction is complete , the nano-silver colloid solution with a particle size of 5-30nm can be obtained.

[0039] The obtained nano-silver colloid solution is used for the anti-mite and antibacterial treatment of textiles, using a padding process, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com