Efficient mite-proof viscose

A viscose fiber and anti-mite technology, applied in the field of high-efficiency anti-mite viscose fiber, can solve the problems of low utilization rate of effective anti-mite agent, slow anti-mite effect, poor anti-mite durability, etc., and achieve good anti-mite effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

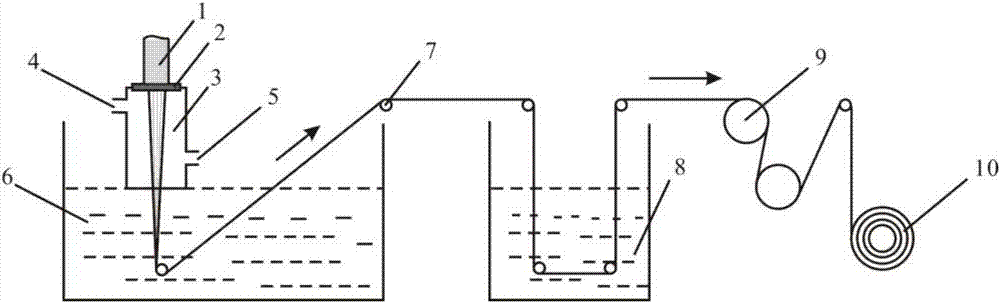

Image

Examples

Embodiment 1

[0028] Present embodiment is a kind of high-efficiency anti-mite viscose fiber, the surface layer of this high-efficiency anti-mite viscose fiber is mixed with anti-mite agent, and the anti-mite agent in the present embodiment is isobornyl cyanothioglycolate, and spinning speed is 300m / min, the fineness of high-efficiency anti-mite viscose fiber is 10dtex.

[0029] The preparation steps of the high-efficiency anti-mite viscose fiber of the present embodiment are as follows:

[0030] 1) Preparation of viscose spinning stock solution: take wood and prepare viscose spinning stock solution 1 through impregnation, pressing, crushing, aging, yellowing, dissolution, ripening, and defoaming and filtering processes; wherein, viscose spinning stock solution 1 The weight percent concentration of cellulose is 23%;

[0031] 2) Preparation of coagulation bath: sulfuric acid, sodium sulfate, zinc sulfate, aluminum sulfate and fatty alcohol polyoxyethylene ether are mixed and dissolved in w...

Embodiment 2

[0040] This embodiment is a high-efficiency anti-mite viscose fiber. The surface layer of this high-efficiency anti-mite viscose fiber is mixed with an anti-mite agent. The denier of the anti-mite viscose fiber is 30dtex.

[0041] The preparation steps of the high-efficiency anti-mite viscose fiber of the present embodiment are as follows:

[0042] 1) Preparation of viscose spinning stock solution: take wood and prepare viscose spinning stock solution 1 through impregnation, pressing, crushing, aging, yellowing, dissolution, ripening, and defoaming and filtering processes; wherein, viscose spinning stock solution 1 The weight percent concentration of cellulose is 28%;

[0043] 2) Preparation of coagulation bath: sulfuric acid, sodium sulfate, zinc sulfate, aluminum sulfate and sodium alkyl sulfate are mixed and dissolved in water to obtain coagulation bath 6; in the prepared coagulation bath 6, sulfuric acid 115g / L, Sodium sulfate 320g / L, zinc sulfate 10g / L, aluminum sulfate 4...

Embodiment 3

[0052] This embodiment is a kind of high-efficiency anti-mite viscose fiber, the surface layer of this high-efficiency anti-mite viscose fiber is mixed with anti-mite agent, the anti-mite agent in the present embodiment is N, N-diethyl-m-toluamide, spinning speed It is 400m / min, and the fineness of high-efficiency anti-mite viscose fiber is 20dtex.

[0053] The preparation steps of the high-efficiency anti-mite viscose fiber in this embodiment are as follows: wherein, the weight percent concentration of cellulose in the viscose spinning stock solution 1 is 26%;

[0054] 1) Preparation of viscose spinning stock solution: take wood and prepare viscose spinning stock solution 1 through impregnation, pressing, crushing, aging, yellowing, dissolution, ripening, defoaming and filtration;

[0055] 2) Preparation of coagulation bath: sulfuric acid, sodium sulfate, zinc sulfate, aluminum sulfate and sodium alkyl succinate sulfonate are mixed and dissolved in water to obtain coagulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com