Anti-mite polyamide fiber and preparation method thereof

A technology of polyamide fiber and anti-mite polyamide, applied in the field of polyamide fiber, can solve the problems of easy elution and loss of anti-mite agent, human body irritation, poisoning, etc., so as to improve the stability of production process and product quality, and not easy to run off. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

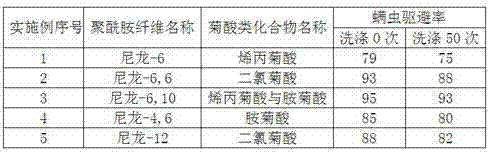

Examples

preparation example Construction

[0033] A method for preparing anti-mite polyamide fiber, which is prepared from the following raw materials in weight percentage: 100-250 parts of polyamide fiber, 1-5 parts of chrysanthemum acid compound, 200-500 parts of solvent, and 0.10-10 parts of dehydrating agent parts and a small amount of catalyst.

[0034] (1) Put the raw materials into the reactor according to the ratio of 1-5 parts of chrysanthemic acid compound and 200-500 parts of solvent, and dissolve at 40°C-110°C;

[0035] (2) Add 0.10-10 parts of dehydrating agent and 0.1-0.5 parts of catalyst to the solution obtained in step (1), mix well, then add 100-250 parts of polyamide fiber, adjust the temperature to the reflux temperature, and dry in ultrasonic or Reflux reaction under inert gas stirring for 1~10h;

[0036] (3) After the reaction is completed, take out the polyamide fiber and centrifuge to recover the solution;

[0037] (4) The polyamide fibers from which the solution has been removed by centrifuga...

Embodiment 1

[0039] (1) Put the raw materials into the reactor according to the ratio of 1 part of allylchrysanthemic acid and 200 parts of ethanol, and dissolve at 70°C;

[0040] (2) Add 2 parts of phosphorus pentoxide and 0.1 part of hydrochloric acid to the solution obtained in step (1), mix well, then add 100 parts of nylon-6 fiber, adjust the temperature to the reflux temperature, and reflux for 1 hour under ultrasonic stirring ;

[0041] (3) After the reaction is completed, take out the nylon-6 fiber and centrifuge to recover the solution;

[0042] (4) The nylon-6 fibers from which the solution has been removed by centrifugation are washed with water at 40°C until neutral and then dried to obtain the anti-mite nylon-6 fibers.

Embodiment 2

[0044] (1) Put the raw materials into the reactor according to the ratio of 5 parts of permethrin and 500 parts of xylene, and dissolve at 110°C;

[0045] (2) Add 10 parts of anhydrous sodium sulfate and 0.5 parts of hydrobromic acid to the solution obtained in step (1), mix well, then add 250 parts of nylon-6,6 fiber, adjust the temperature to reflux temperature, and dry in nitrogen Reflux reaction under stirring for 5h;

[0046] (3) After the reaction is completed, take out the nylon-6,6 fiber, and centrifuge to recover the solution;

[0047] (4) The nylon-6,6 fibers from which the solution has been removed by centrifugation are washed with water at 40° C. to neutral and then dried to obtain the anti-mite nylon-6,6 fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com