Paint spraying method for furniture production

A technology of furniture and sanding primer, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., can solve the problems of dull paint effect, low construction efficiency, poor environmental protection, etc., and achieve increased hardness and Effects of plumping, improving aesthetics, and enhancing protective properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A spray paint method for producing furniture. The method adopts UV-brushing filling putty, UV-spraying sanding primer and spraying soft topcoat for spray painting construction. The specific steps are as follows:

[0021] 1) Sand the plain board with 100# sandpaper;

[0022] 2) Manually wipe the surface of the substrate with UV-water-based wiper, the dosage is 8~12g / m2, and the infrared ray is dried at 70℃ / min;

[0023] 3) Manually brush with UV-brush filling putty, the dosage is 30~40g / m2, 180mj / cm2 · After UV curing, sand with 240# sandpaper;

[0024] 4) Manual spray with UV-spray sanding primer, dosage 40~50g / m2; 180mj / cm2·UV curing and sanding with 320# sandpaper; second hand spray with UV-spray sanding primer, dosage 40~ 50g / m2; 180mj / cm2·After UV curing, sand with 600# sandpaper;

[0025] 5) Manually spray with UV-spray soft-gloss topcoat, the dosage is 40~50g / m2; 260mj / cm2·UV curing.

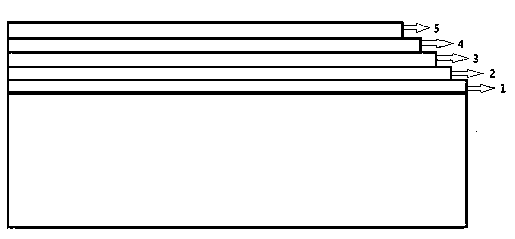

[0026] Such as figure 1 As shown, the board includes a substrate layer 1, a UV-brushing f...

Embodiment 2

[0031] Another painting method for producing furniture, the steps are the same as in Example 1, except that the three coating components are different.

[0032] The components of the UV-brushing and filling putty in this embodiment and their weight ratio are: 100% UV curable resin 35%; defoamer 0.1%; substrate wetting agent 0.3%; dispersant 0.5%; thixotropic Agent 5%; photoinitiator 7%; filler 20%; the balance is monomer.

[0033] The components and weight ratio of the sanding primer of this embodiment are: 100% UV curable resin 35%; defoamer 0.6%; leveling 0.05%; dispersant 1%; anti-settling agent 0.4%; light Initiator 6%; filler 15%; the balance is monomer.

[0034] The topcoat of this embodiment is a high gloss topcoat. Compared with Example 1, fillers and matting agents are eliminated. The components and weight ratio of the soft topcoat are: 100% UV curable resin 40% ; Antifoaming agent 0.7%; leveling 1%; wetting agent 0.3%; photoinitiator 5%; the balance is monomer.

[0035] Am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com