A broadband white light long afterglow material and its preparation method

A long afterglow material, white light technology, applied in luminescent materials, chemical instruments and methods, sustainable architecture, etc., can solve the problem of no one or no long afterglow material found, and achieve the effect of increasing afterglow time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] According to the following composition: the base material is Zn Z Al Y Ge X o (Z+1.5Y+2X) ; Among them, X=2, Y=1, Z=4, no doping elements; Weigh zinc oxide, aluminum oxide, germanium oxide respectively, after grinding and mixing, pre-burn at 900°C for 3 hours, take out, and grind again , fired at 1300°C for 3 hours.

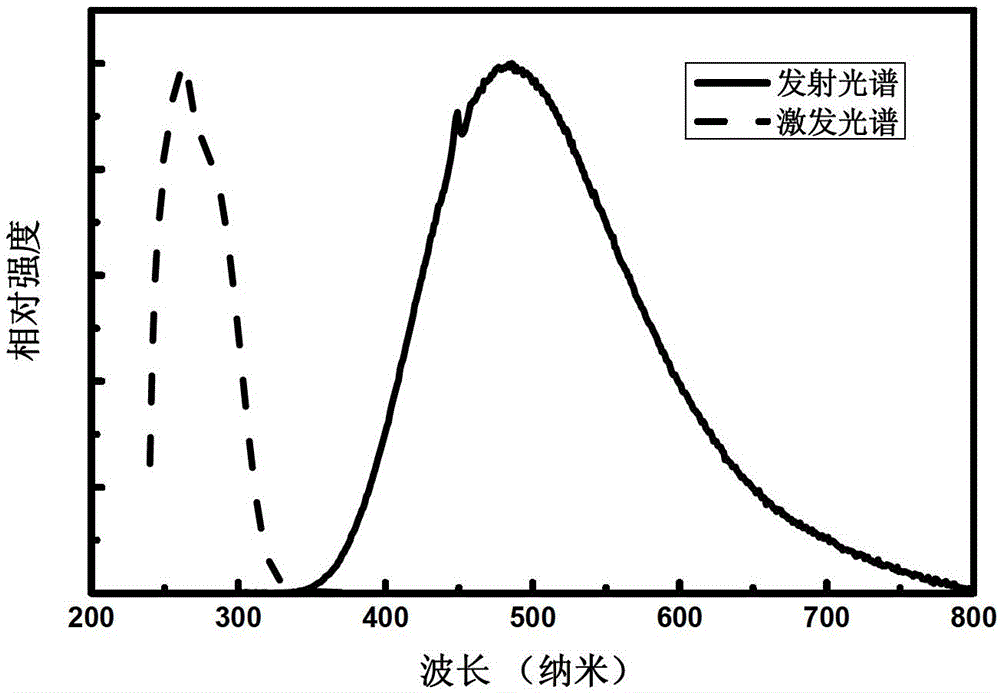

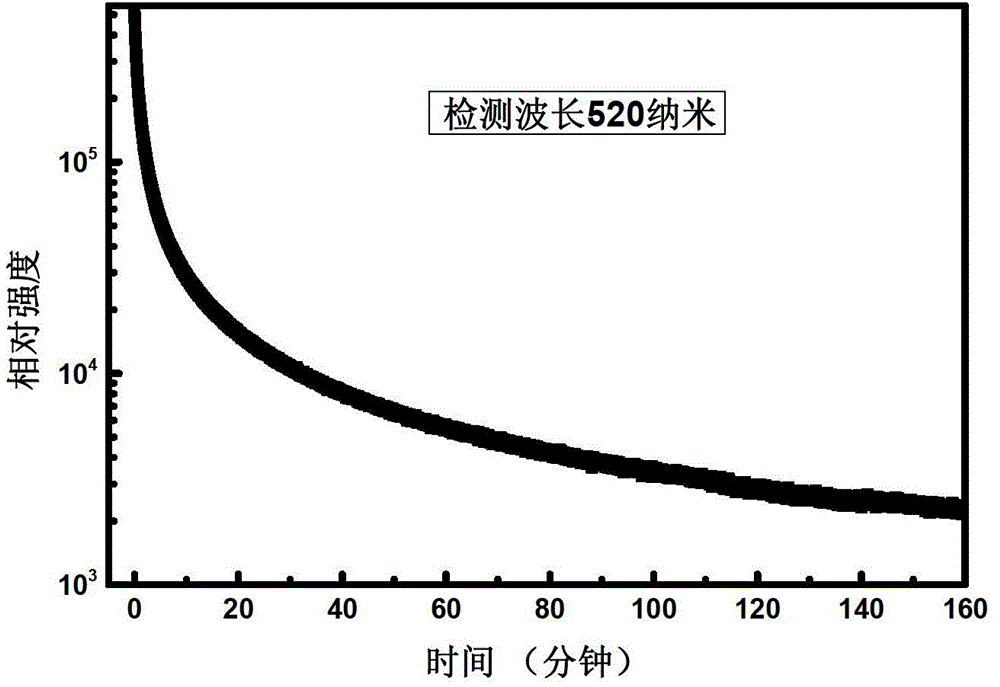

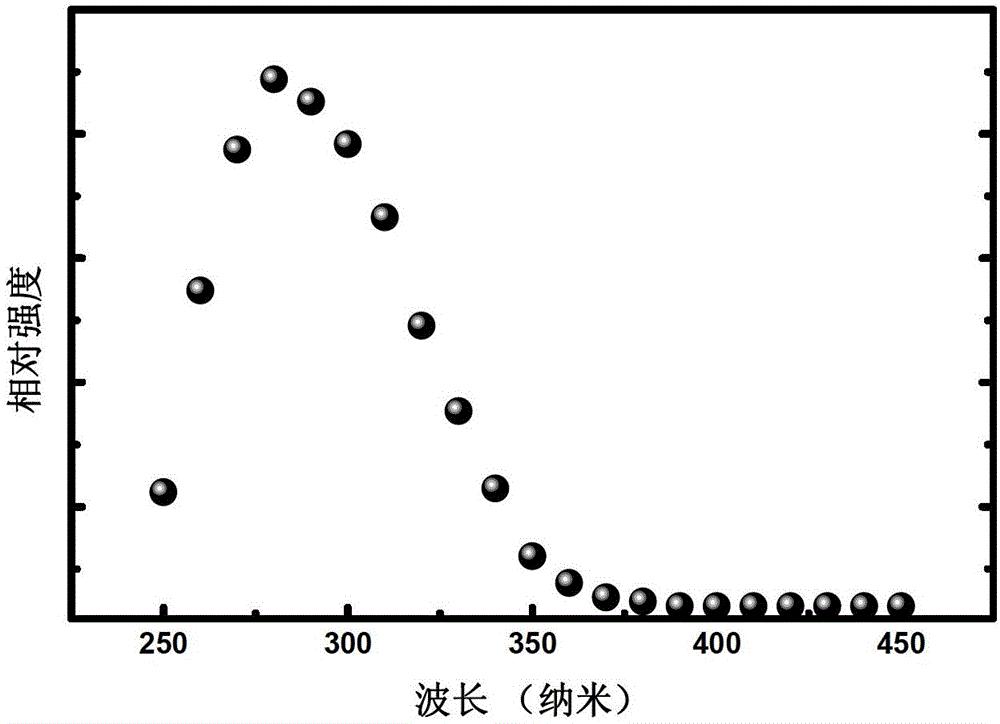

[0035] The fluorescence spectrum of the sample prepared in this embodiment is as follows: figure 1 As shown, the luminescence of 300nm-800nm is emitted under the excitation of 280nm, and the luminescence peak is located at 500nm, and the fluorescence emission of 500nm corresponds to two excitation peaks in the range of 200nm-350nm, which are 260nm and 280nm respectively. figure 2 The long afterglow luminescence decay spectrum of the sample prepared in this example is shown, and the afterglow decay 3 hours after the excitation is stopped, and the exponential decay curve shows the trapping mechanism. image 3 The long afterglow excitation spectrum of...

Embodiment 2

[0037] According to the following composition: the base material is Zn Z Al Y Ge X o (Z+1.5Y+2X) ; Among them, X=2, Y=1, Z=4, the doping element is Ca; Ca 2+ The doping amount is 5mol%; zinc oxide, aluminum oxide, calcium oxide, and germanium oxide were weighed, ground and mixed, pre-fired at 900°C for 3 hours, taken out, ground again, and fired at 1300°C for 3 hours. Figure 4 It is a comparison chart of the long afterglow attenuation spectra of the sample prepared in Example 1 and the sample prepared in Example 2 of the present invention. It is found that after doping with alkaline earth metals, the afterglow performance of the sample is enhanced.

Embodiment 3

[0039] According to the following composition: the base material is Zn Z Al Y Ge X o (Z+1.5Y+2X) ; Among them, X=0.5, Y=1, Z=1, no doping elements; Weigh zinc oxide, aluminum oxide, germanium oxide respectively, after grinding and mixing, pre-burn at 800°C for 1 hour, take out, and grind again , fired at 1500°C for 5 hours. After testing its luminescence spectrum, the luminescence peak is located at 520nm, and the afterglow time is greater than 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com