Co-immobilized gel particles applied to high osmotic pressure environment food and application of co-immobilized gel particles

A technology of high osmotic pressure and gel particles, which is applied in the direction of immobilization on/in organic carriers, application, food preparation, etc., and can solve the problem of incompatible solute and enzyme co-immobilization technology application and lack of compatibility Problems such as solute compound optimization, to improve the ability to adapt to hypertonic environment, improve the flavor of soy sauce, and improve the effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

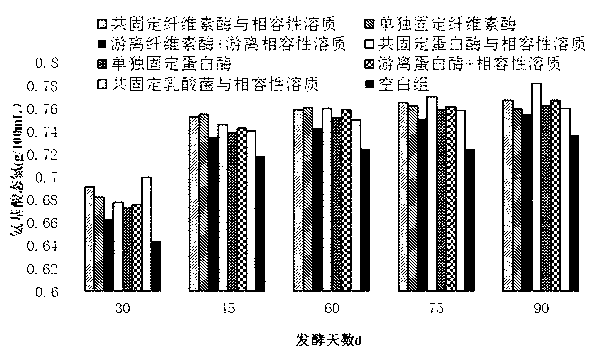

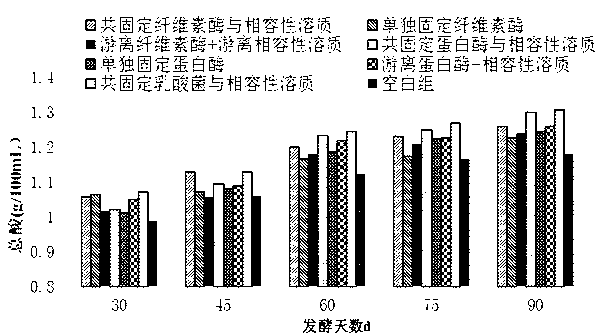

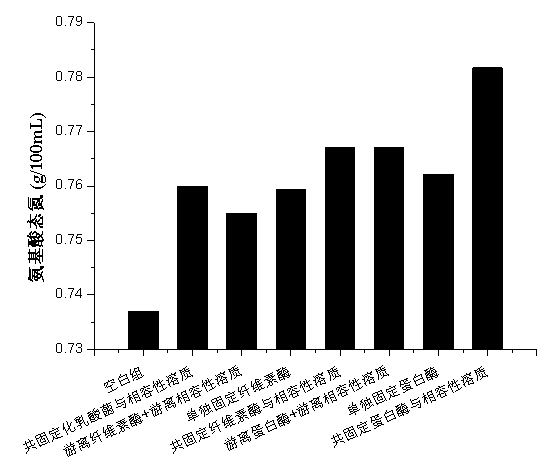

[0044] Example 1: (Co-immobilized protease + solute)

[0045] The protease (5000~10000U / g) enzyme solution, which accounts for 3% (w / w) of the embedding material (sodium alginate), and the glycerol, 3.0‰ betaine and 3.0‰ of the enzyme solution (protease enzyme solution) mass fraction respectively Mix 5.0‰ of trehalose evenly, add it to the sterilized sodium alginate solution with a concentration of 4% by mass, and pump it out through a rubber tube with a peristaltic pump after mixing, and drop in CaCl with a concentration of 3% by mass. 2 In the solution, the beads are cross-linked, and the beads are calcified overnight at 4°C to remove the CaCl on the surface of the beads. 2 Solution, get co-immobilized gel particles.

[0046] S1. Prepare a song according to conventional methods;

[0047] S2. Mix the koji and brine (18%, w / v) according to the mass ratio of 1:2.3 to make the mash or sauce mash, and then ferment it in the upper tank; when the upper tank is fermented or two weeks after...

Embodiment 2

[0050] Example 2 (Co-immobilized cellulase + solute)

[0051] The cellulase (700EGU / g, density 1.2g / mL) enzyme solution accounting for 3% (w / w) of the embedding material (polyethylene glycol) and the sugar beet accounting for 3.0‰ (w / w) of the mass of the enzyme solution The alkali is evenly mixed and added to the sterilized polyethylene glycol solution with a concentration of 2.5% by mass. After the mixture is evenly mixed, it is pumped out through the rubber tube with a peristaltic pump, and the CaCl with a concentration of 3% by mass is dropped into it. 2 In the solution, the beads are cross-linked, and the beads are calcified overnight at 4°C to remove the CaCl on the surface of the beads. 2 Solution, get co-immobilized gel particles.

[0052] S1. Prepare a song according to conventional methods;

[0053] S2. Mix the koji and salt water (18%, w / v) at a mass ratio of 1:2.5 to make a mash or sauce mash, and then ferment it in the top tank; when the top tank is fermented or two week...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com