Composite soil nailing wall slope support method

A composite soil nail and side slope technology, which is applied in excavation, sheet pile wall, construction and other directions, can solve the problems of difficult to ensure construction quality, cumbersome construction technology, low efficiency, etc., and achieves improved construction quality, high safety, and general use. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the drawings and specific embodiments.

[0018] A method for supporting the slope of a composite soil-nail wall includes the following steps:

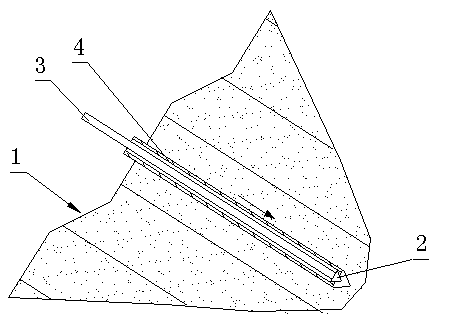

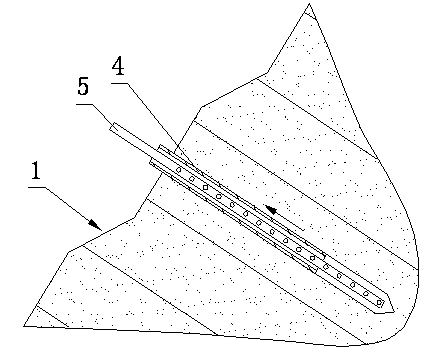

[0019] 1) Determine the location of the drilling hole: lay multiple soil nail locations on the composite soil nail wall on the backfill loose surface or slope 1 under high weathering geological conditions that need to be supported, and use this location as the drilling location.

[0020] 2) Hole formation: first align the drill bit 2 to the drilling position, the drill rig drives the drill rod 3 to drive the drill bit 2 to drill. During the drilling process, the follow-up casing 4 sleeved outside the drill rod 3 follows the drill rod 3 Gradually press inward until it reaches the design depth requirement; then exit the drill pipe 3 and the drill bit 2 through the drill. Such as figure 1 As shown, the follow-up casing 4 should be followed by compaction d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com