Method for actively controlling motion of coal mine critical layers by using strip filling walls

A strip filling and active control technology, applied in the fields of filling, ground mining, mining equipment, etc., can solve problems such as damage and surrounding rock damage, and achieve the effect of avoiding accumulation, improving safety level, and preventing impact ground pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

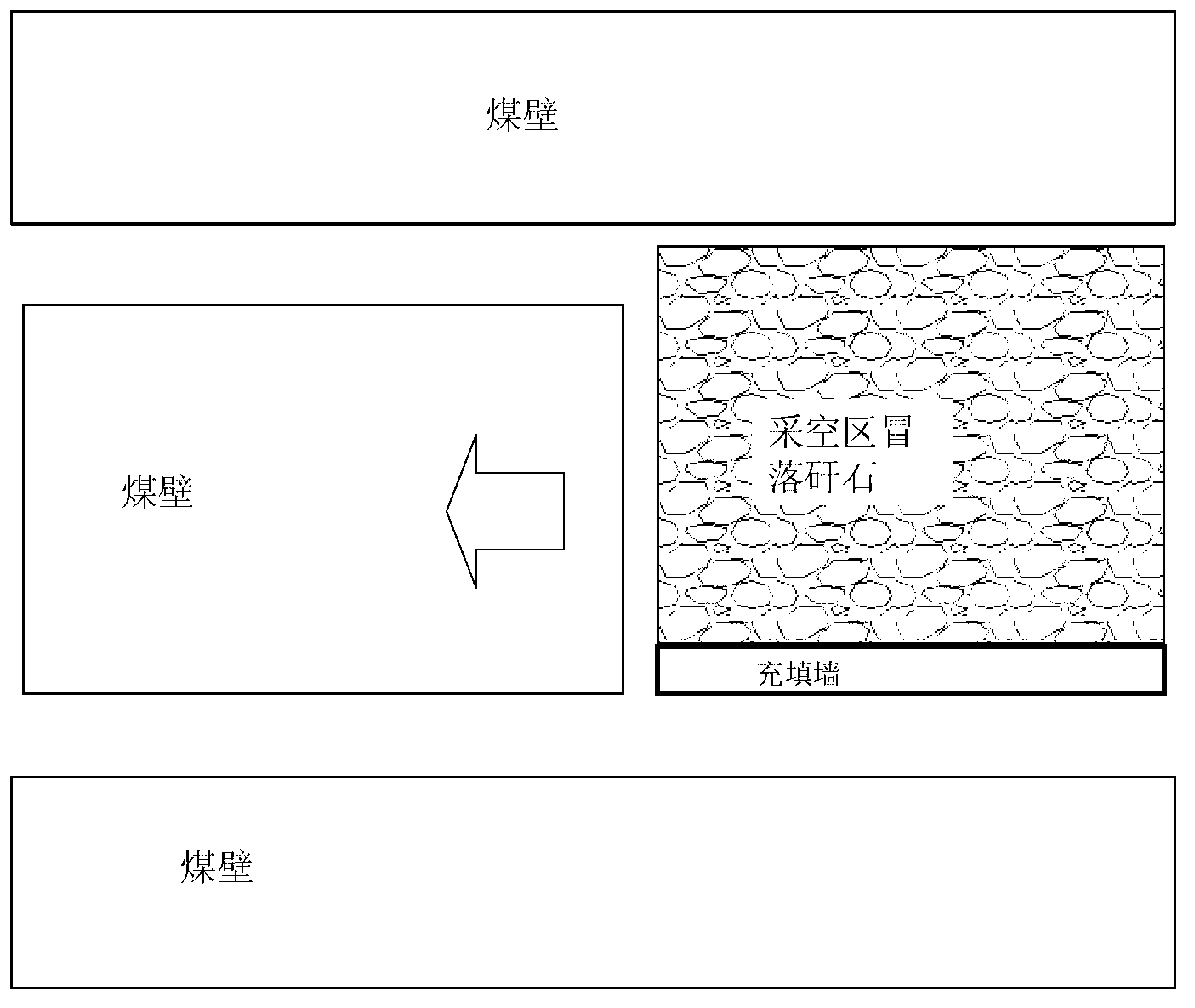

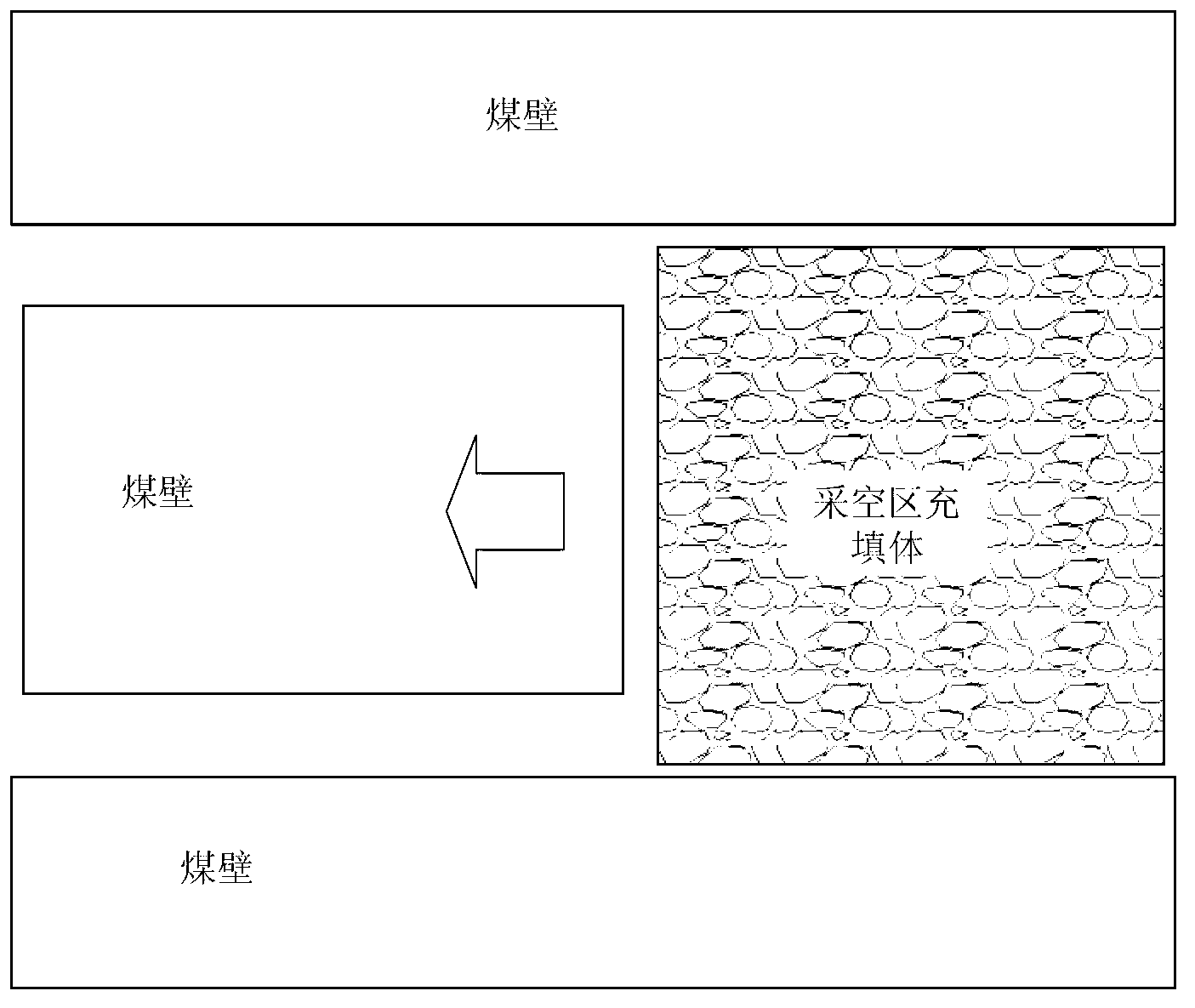

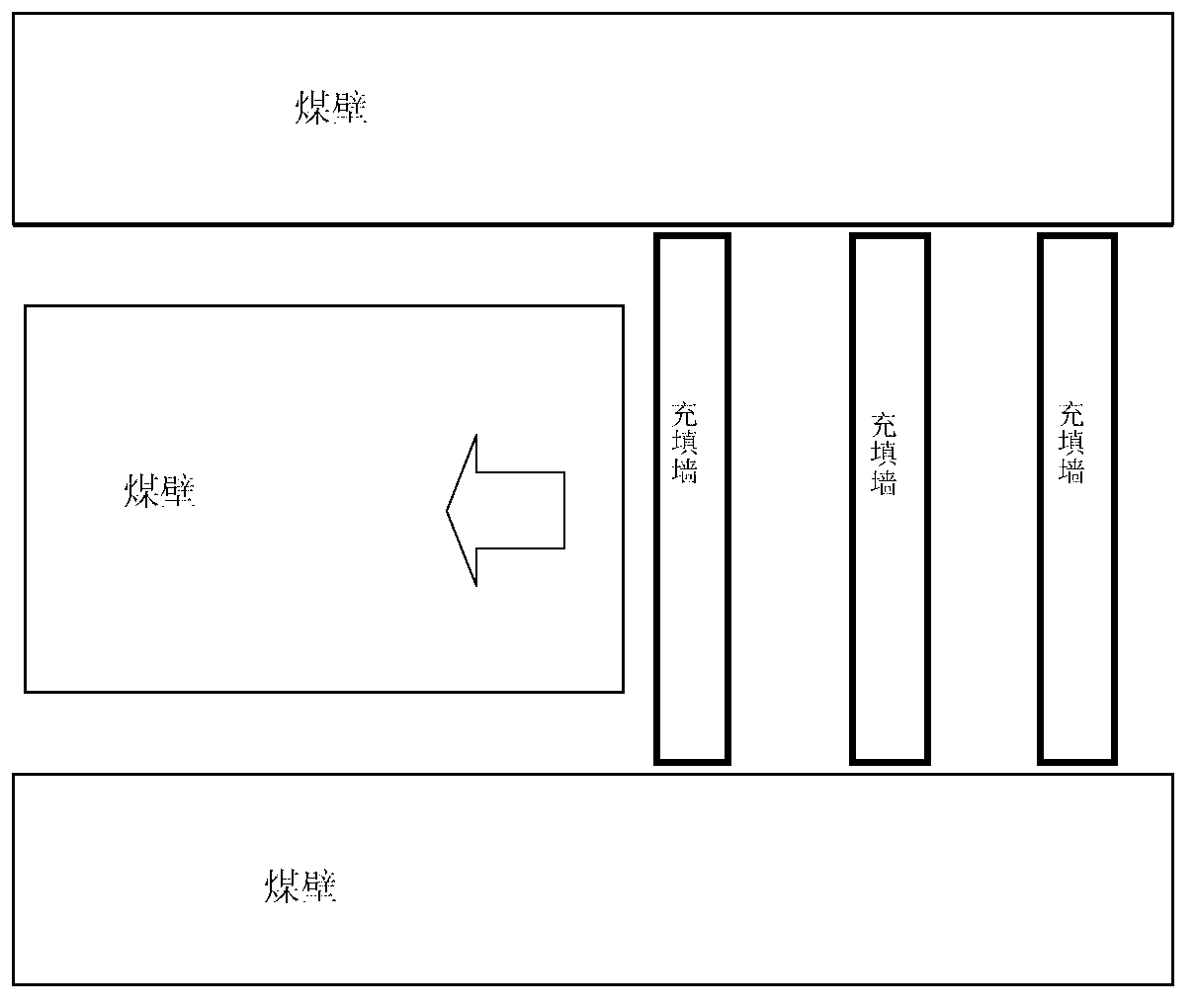

[0032] control figure 1 , assuming that the burial depth of the coal seam in a working face is 700m, the thickness of the coal seam is 3.0m, the immediate roof is siltstone, the thickness is 9.3m, the key layer is medium sandstone, the thickness is 25m, and the bulk density is 2.7t / m 3 , the compressive strength of the filling body of wall is that 40Mpa is the basic condition to illustrate the implementation steps of the present invention:

[0033] First drill cores, assuming that the measured uniaxial tensile strength value of the sandstone in the key layer is 10.49MPa;

[0034] 1. Calculate the initial fracture step of the key layer:

[0035] C 0 = 2 m σ t × 100 γ z = 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com