Compression method and compression device for low-concentration oxygen-containing coalbed methane

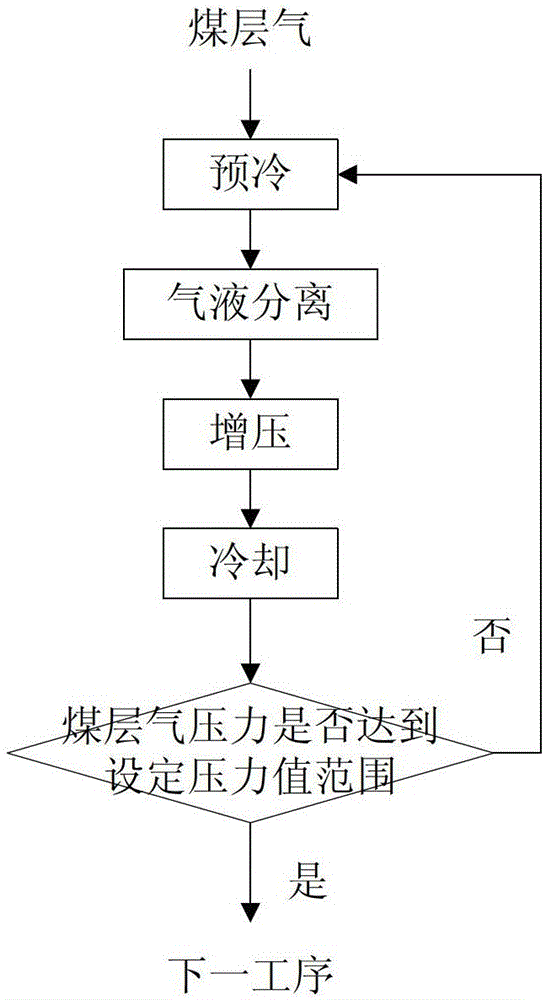

A compression method and coalbed methane technology, applied in the field of gas compression, can solve the problems of many compression stages, high compression energy consumption, expansion of coalbed gas explosion range, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

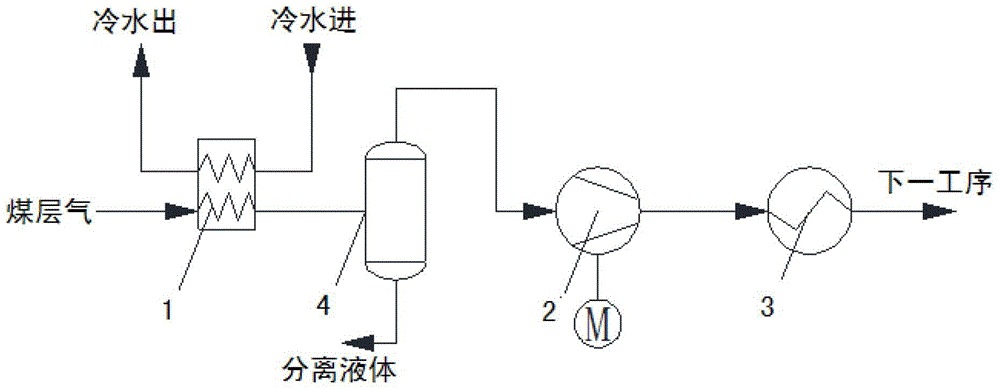

[0038] like figure 2 Shown is a schematic structural view of the first embodiment of the compression device for low-concentration oxygen-containing coalbed methane in the present invention. The compression device for low-concentration oxygen-containing coalbed methane in this embodiment includes at least one stage of compression systems connected in series. The compression system includes a pre-cooling heat exchanger 1, a compressor 2, and a cooler 3. The coal bed of the pre-cooling heat exchanger 1 The gas outlet is connected to the coalbed gas inlet of the compressor 2, and the coalbed gas outlet of the compressor 2 is connected to the coalbed gas inlet of the cooler 3. By setting the pre-cooling heat exchanger 1, the coal bed gas can be pre-cooled before pressurization and compression. The pre-cooling heat exchanger 1 of this embodiment uses cold water to provide cooling capacity, and the temperature of the cold water is 3°C to 5°C. The cooler 3 in this embodiment is a w...

no. 2 example

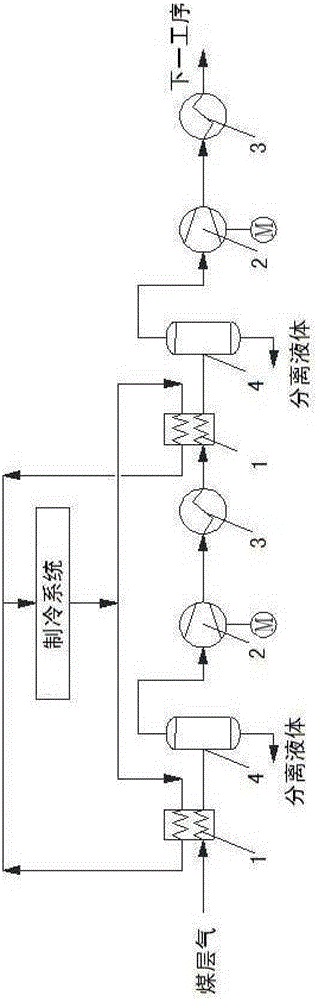

[0046] like image 3Shown is a schematic structural view of the second embodiment of the compression device for low-concentration oxygen-containing coalbed methane of the present invention. The compression device for low-concentration oxygen-containing coalbed methane in this embodiment includes at least one stage of compression systems connected in series. The compression system includes a pre-cooling heat exchanger 1, a compressor 2, and a cooler 3. The coal bed of the pre-cooling heat exchanger 1 The gas outlet is connected to the coalbed gas inlet of the compressor 2, and the coalbed gas outlet of the compressor 2 is connected to the coalbed gas inlet of the cooler 3. By setting the pre-cooling heat exchanger 1, the coal bed gas can be pre-cooled before pressurization and compression. The compression device for low-concentration oxygen-containing coalbed methane in this embodiment also includes a refrigeration system for providing cooling capacity to the precooling heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com