A heat exchange device for indoor heating

A technology of heat exchange device and heat mold, which is applied in the directions of household heating, household heating, application, etc., can solve the problems of high power consumption and low thermal efficiency of electric heating devices, and achieves low production cost, improved temperature uniformity and exchange rate. The effect of high thermal efficiency and thermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

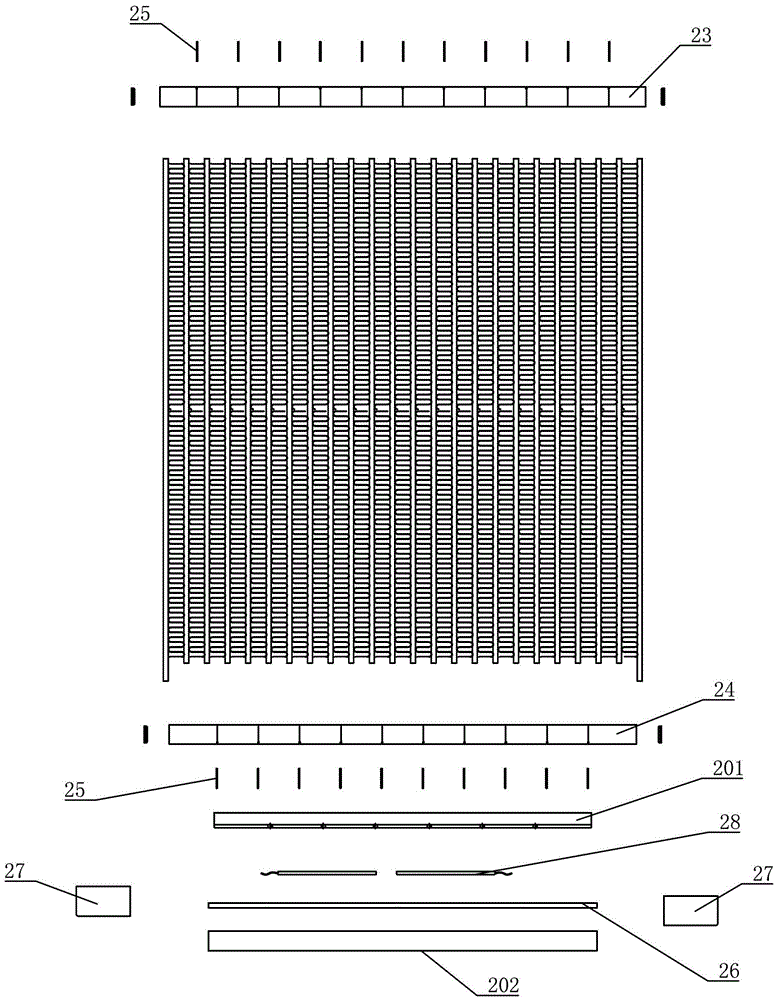

[0030] refer to Figure 1 to Figure 12 , a heat exchange device for indoor heating of the present invention comprises

[0031] It includes a casing 1, a heat exchange module unit 2 and a fan 3. The fan 3 is arranged at the rear end of the casing 1 to blow cold air to assist the heat exchange module unit 2 to dissipate heat. The heat exchange module unit 2 is arranged at the bottom of the casing 1. Front end, which includes:

[0032] Serpentine microporous flat tubes bent into a serpentine shape or a group of microporous flat tubes composed of several microporous flat tubes 21 arranged in parallel and connected in a serpentine shape, two adjacent straight microporous flat tubes in the serpentine microporous flat tubes Fins 22 are arranged between pipe sections or between two adjacent microporous flat tubes 21 in the microporous flat tube group. The microporous flat tubes 21 in the tube group are connected by welding. Of course, the fins 22 and the flat tubes can also be integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com