A purex process for separating technetium

A process and flow ratio technology, applied in the field of PUREX process for separation of technetium, which can solve the problem of technetium diffusion into the natural environment with long waste supervision years

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Since the main innovation of the present invention lies in the difference in the treatment process for 1AP, the example of the 1A tank is not listed in this embodiment. In order to ensure a more uniform trend of technetium in the process and to reduce the concentration of technetium in high-level radioactive waste liquid, process conditions that are favorable for technetium to enter 1AP are generally adopted. The composition list of 1AP in this embodiment is listed in Table 1.

[0039] Table 1

[0040] 1AP component

concentration

U

92g / L

Pu

0.90g / L

Np

0.06g / L

Tc

0.20g / L

HNO 3

0.18M

[0041] The specific process of separating technetium:

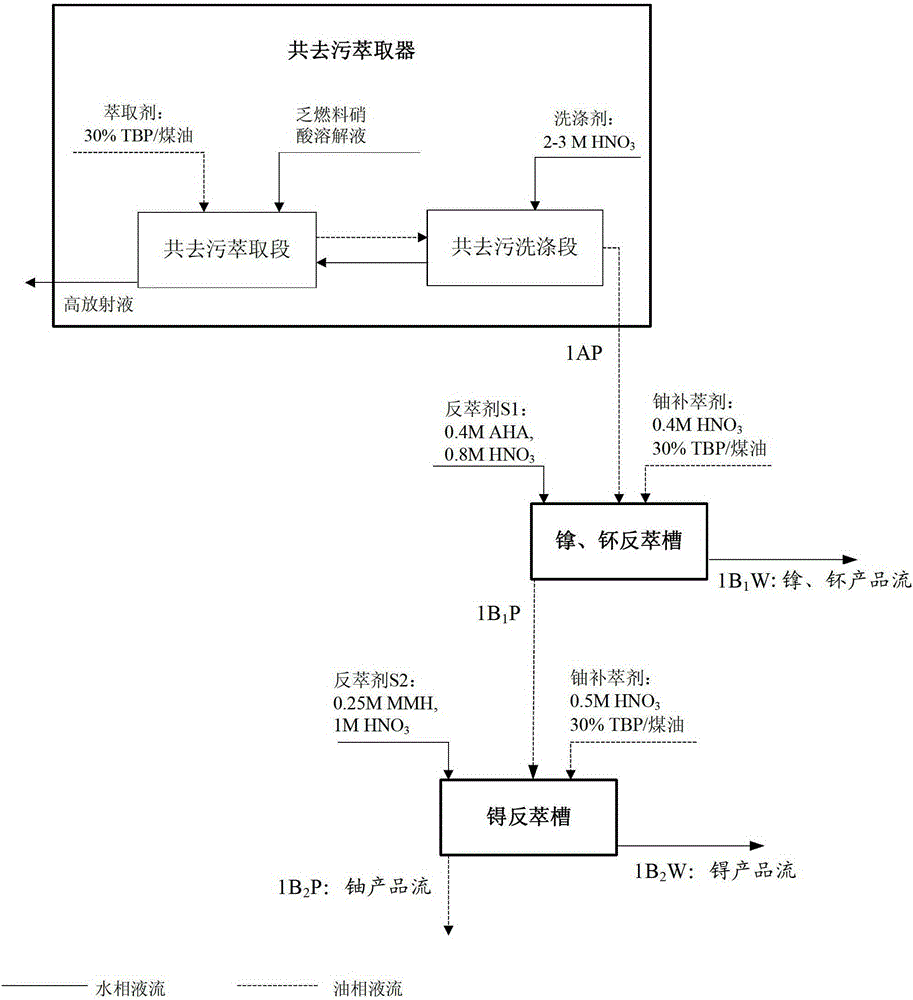

[0042] Co-decontamination and co-extraction process: carried out in a co-decontamination extractor, the process is divided into a co-decontamination extraction section and a co-decontamination washing section, and the obtained 1AP enters the neptunium and pl...

Embodiment 2

[0054] The composition of 1AP in this example is listed in Table 4.

[0055] Table 4

[0056] 1AP component

concentration

U

90g / L

Pu

0.88g / L

Np

0.06g / L

Tc

0.18g / L

HNO 3

0.15M

[0057] The 1AP obtained through the joint decontamination and co-extraction process as shown in Table 4 enters the following process:

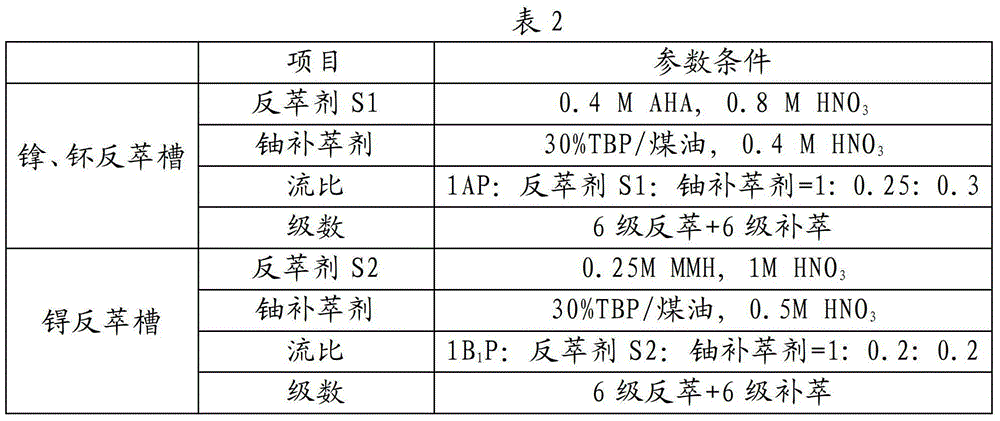

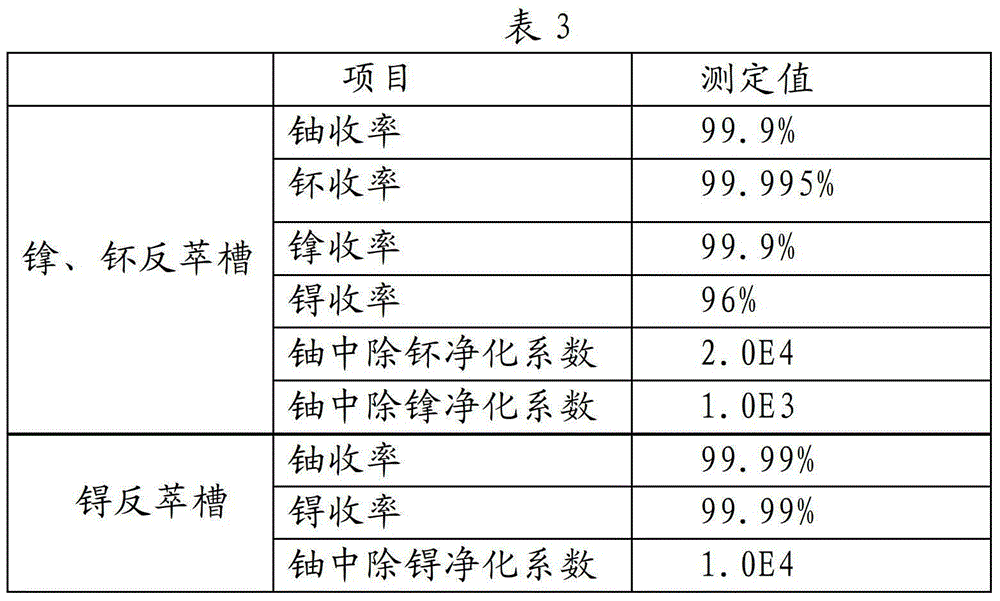

[0058] Neptunium and plutonium stripping process: carried out in the neptunium and plutonium stripping tank, using the process of 6-stage stripping + 6-stage supplementary extraction (see Table 5 for process conditions), and 1B is separated 1 W (containing neptunium, plutonium) and 1B 1 P (with uranium, technetium), 1B 1 P enters the technetium stripping process.

[0059] Technetium reduction and stripping process: carried out in the technetium stripping tank, using the process of 6-stage stripping + 6-stage supplementary extraction (see Table 5 for process conditions), and 1B is separated ...

Embodiment 3

[0066] In this embodiment, the steps of co-decontamination and co-extraction and the steps of stripping neptunium and plutonium are omitted, and the bench experiment process in the technetium stripping tank is mainly described. Process such as figure 1 The technological conditions of the technetium stripping tank shown are shown in Table 7.

[0067]

[0068] In this example, the stripping agent S2 is composed of two reducing agents, and its dosage greatly exceeds the theoretical stoichiometric amount for reducing technetium. One of the reducing agents U(IV) is prepared by electrolytic reduction of U(VI). Sophisticated craftsmanship. Overall, the experiment adopted a relatively conservative process. Excess reductant U(IV) has a relatively high distribution in the organic phase, and uranium will not be lost to the technetium product stream. The excess hydrazine is mainly retained in the water phase, that is, the technetium product, and will not have adverse effects on subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com