Switched reluctance motor and control method thereof

A technology of a switched reluctance motor and a control method, applied in the control field of switched reluctance motor and switched reluctance motor, can solve the problems of large torque ripple, application limitation of switched reluctance motor, high noise, etc., to achieve torque ripple Small, low noise, noise reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0030] The switched reluctance motor in this embodiment is a motor with a double salient pole structure, which has a stator and a rotor. The stator has a stator core and coils wound on the stator core, and each coil is wound on a salient pole. The multiple salient poles on the stator core are evenly arranged in the circumferential direction of the stator core, and the two salient poles facing each other in the radial direction form a pair of salient poles, and the two coils wound on the same pair of salient poles are the same phase coils , the two coils of the same phase coil are connected in series.

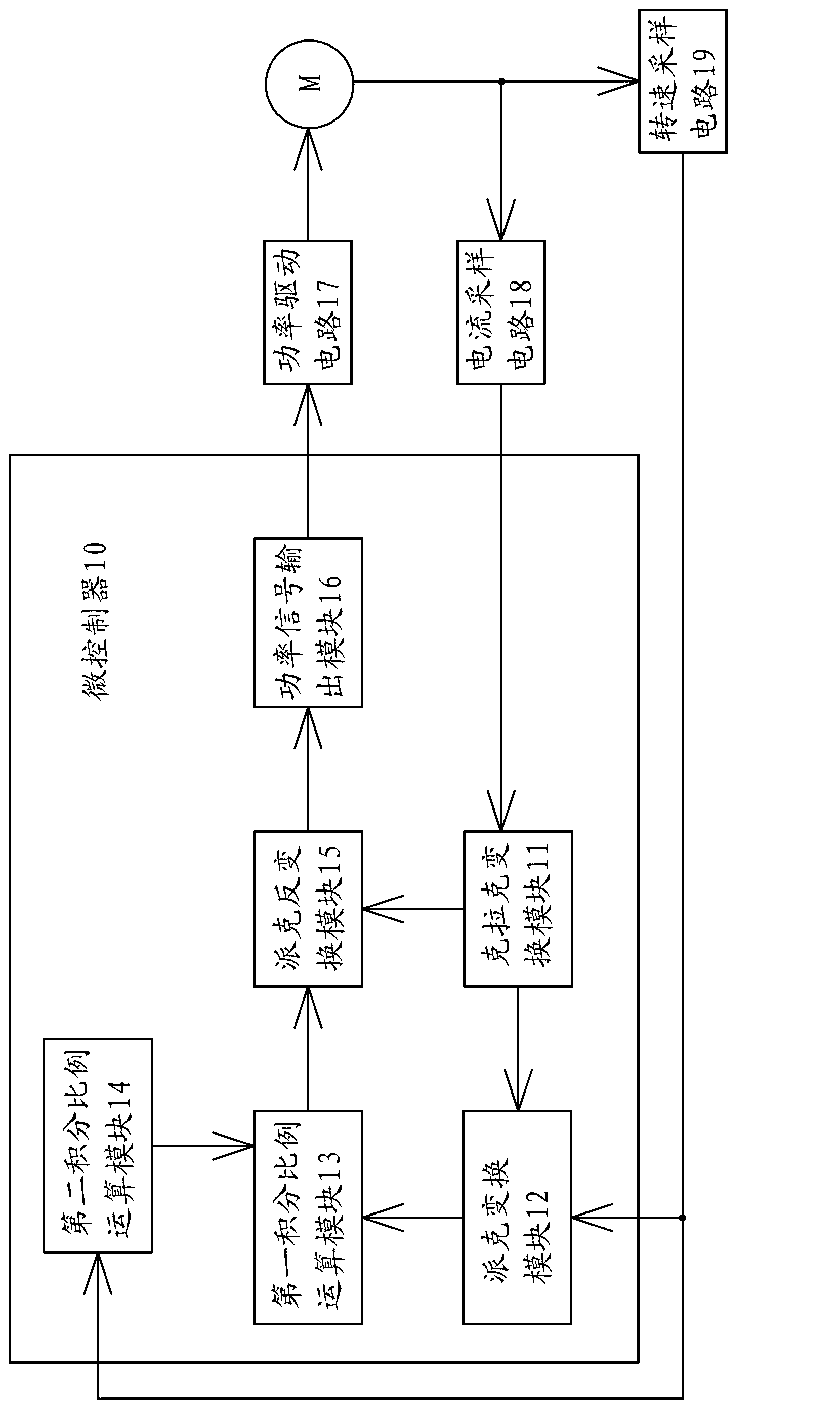

[0031] A switched reluctance motor has a controller for controlling the operation of the motor, such as figure 1 As shown, the controller of this embodiment has a microcontroller 10 , a power drive circuit 17 , a current sampling circuit 18 , and a rotational speed sampling circuit 19 . Microcontroller 10 is the core of controller, and it is single-chip microcomputer, is provid...

no. 2 example

[0093] The switched reluctance motor of this embodiment has a stator and a rotor. The stator has a stator core and a plurality of coils wound on the stator core. Two coils on opposite salient poles are connected in series to form a phase coil. In this embodiment, the number of phases of the coil is n phases.

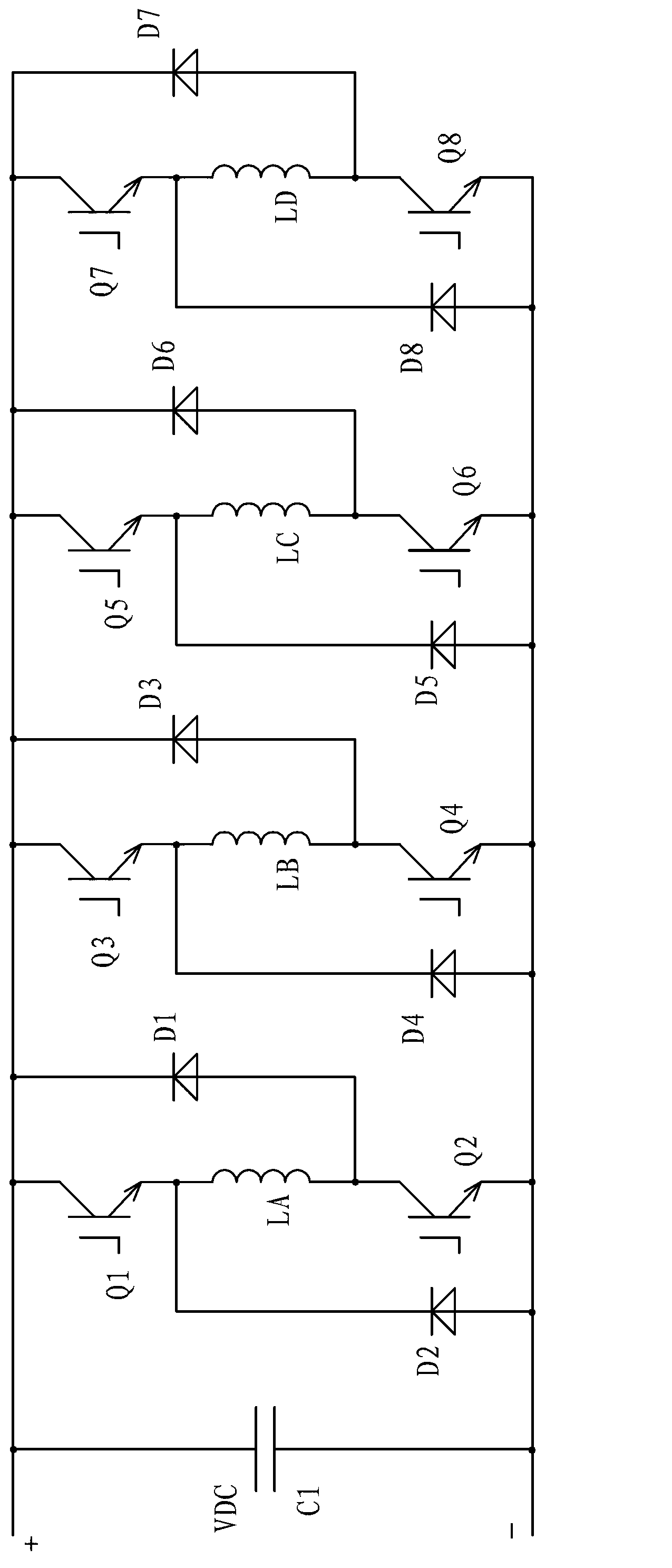

[0094] The switched reluctance motor is also provided with a controller, the controller has a microcontroller, a power drive circuit, a current sampling circuit and a speed sampling circuit, wherein the power drive circuit has n sets of power tubes, and each set of power tubes includes a Two power tubes at both ends of the coil, such as Figure 8 shown.

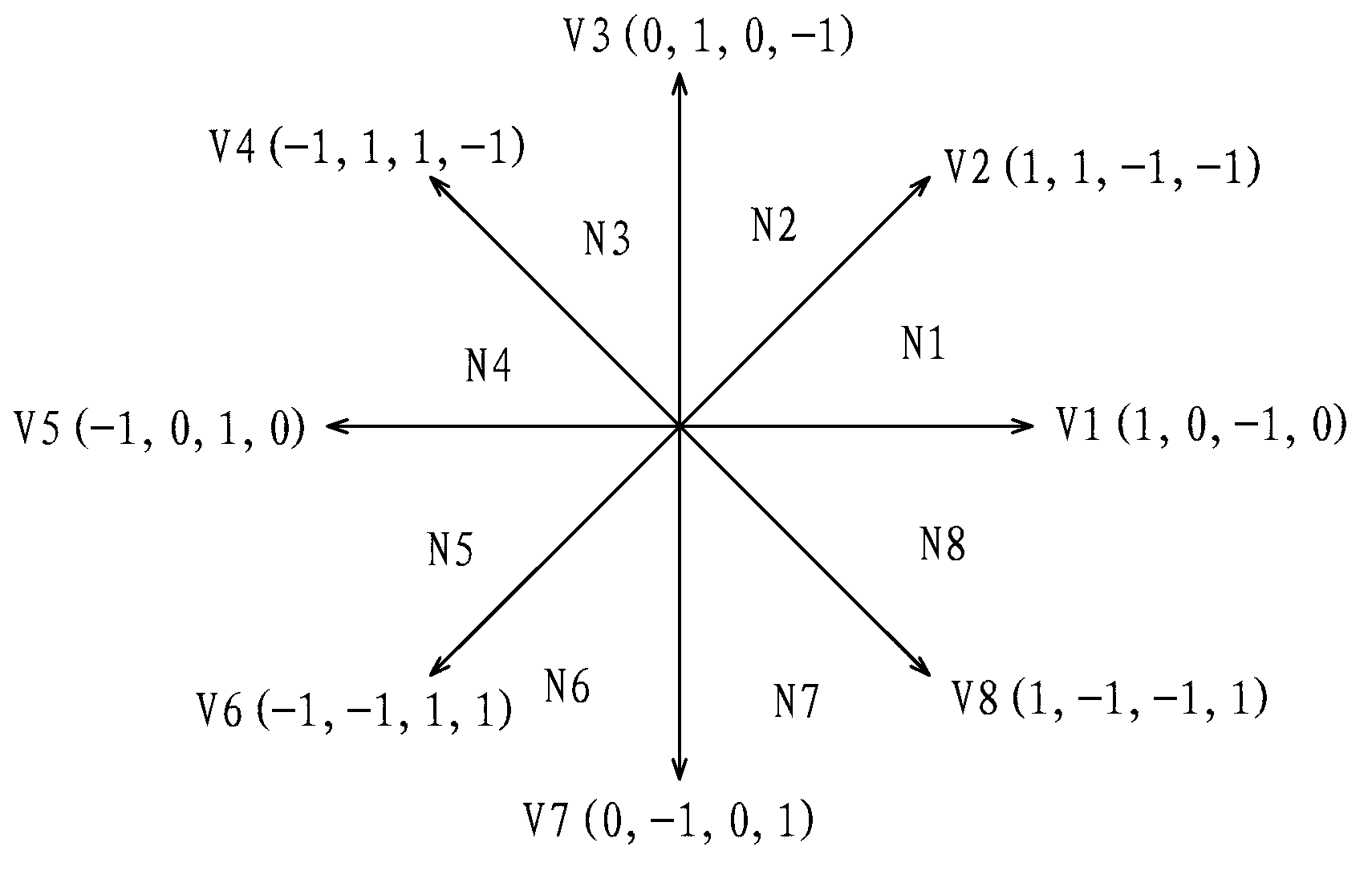

[0095] To control the switched reluctance motor, multiple working states of multiple power transistors are firstly selected. Preferably, the number of selected working states is twice the number of coil phases, so as to facilitate control. And, calculate the voltage vector of the power drive circuit in each working st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com