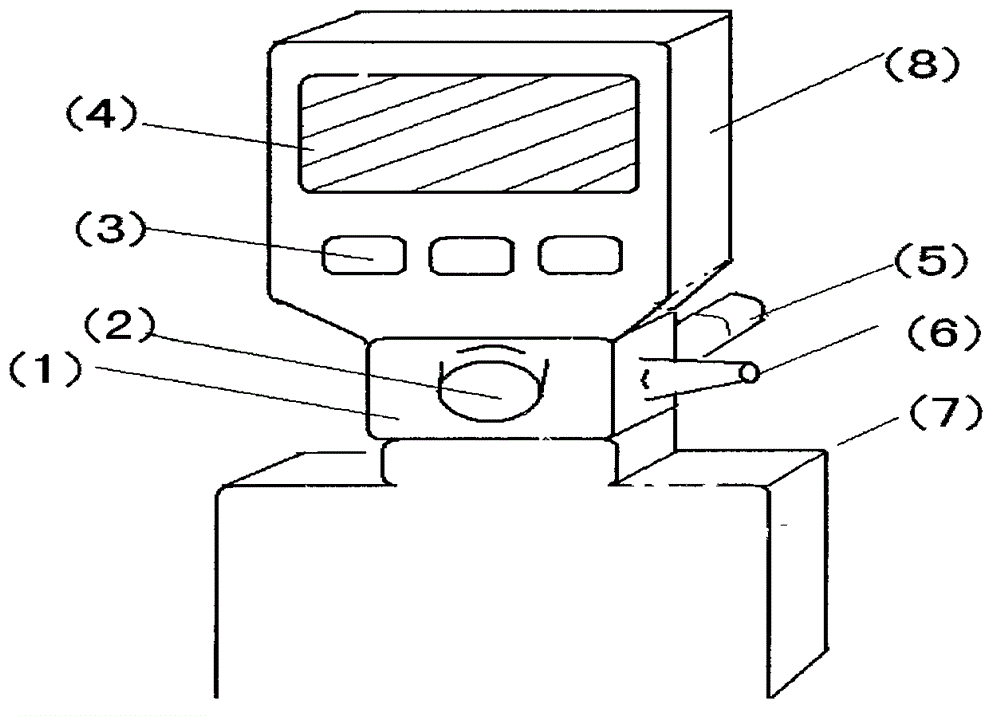

Intelligent oxygen inhaling measuring instrument

A measuring instrument and intelligent technology, applied in the direction of respirators, etc., can solve the problems of high cost, large error, and inability to be widely used in hospitals, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

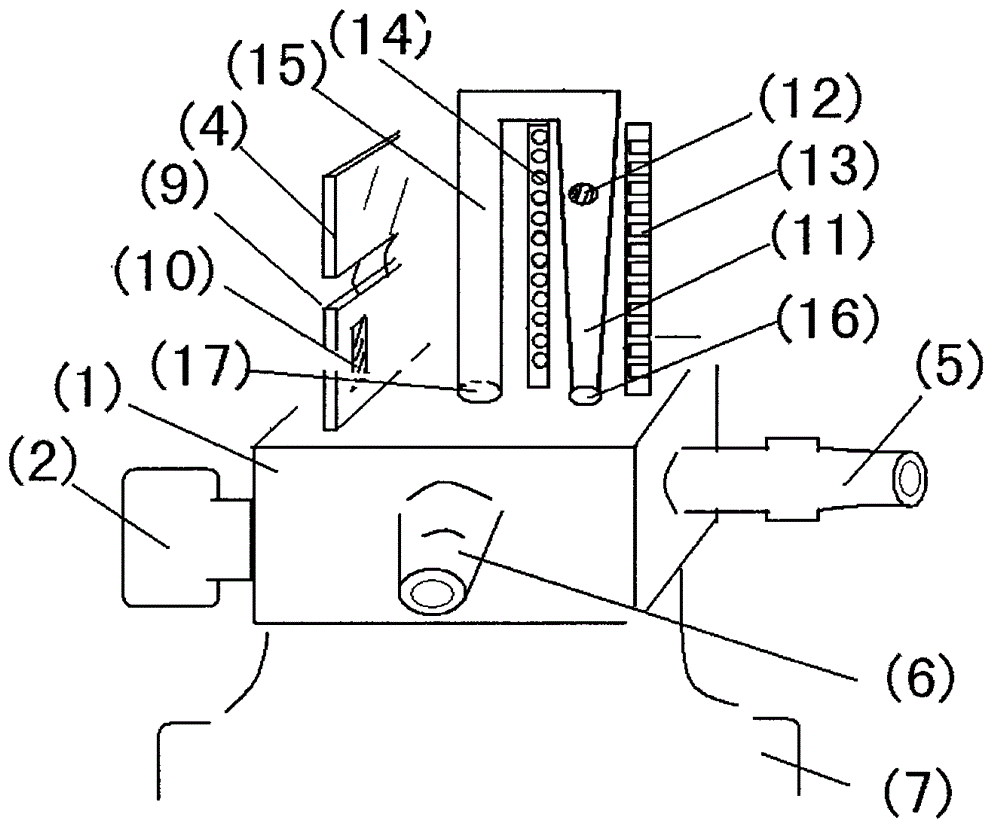

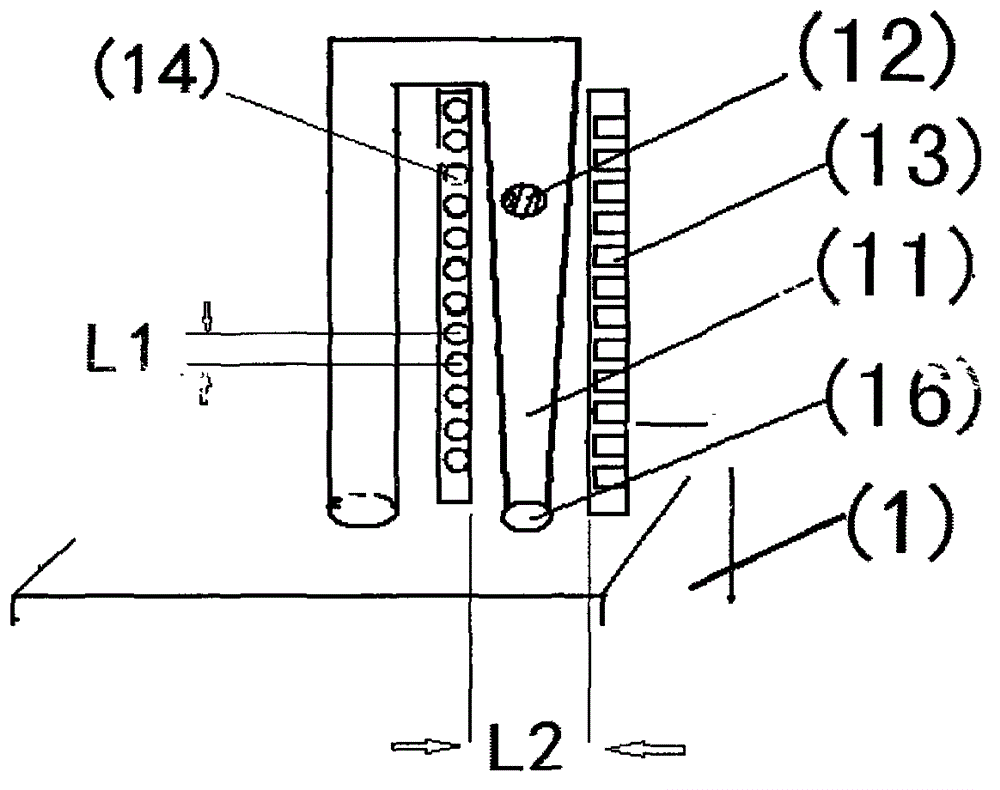

[0034] Embodiment 1: layout design of the optical scanning module. Main technical parameters: the height of the tapered tube (11) is 60mm, the light-emitting diode (13), photodiode / or phototransistor (14) are arranged facing each other, the flow calculation range is 1L-10L, and the error value does not exceed ±2.0%.

[0035] The present invention can pre-produce each component separately, and then produce it by module assembly, and the assembly of electronic components is a common technology, so Embodiment 1 of the present invention only describes the core technical part——the layout design of the optical scanning module in detail. The optical scanning module includes a base (1), a tapered tube (11), a float (12), a light emitting diode (13), a photodiode / or phototransistor (14), an integrated circuit (9) and the like.

[0036] 1. Use PE material to open a mold to produce a tapered tube (11) with a length of 60mm, an inner diameter of the upper end of 6.3mm, and an inner diamet...

Embodiment 2

[0041] Embodiment 2: Establishment of data model of "float position-corresponding flow" in the present invention

[0042] Taking the product prepared in the first embodiment of the present invention as an example, the working method of the present invention is further described:

[0043] 1. The height of the product taper tube (11) prepared in embodiment one is 60mm, and 30 pairs of light-emitting diodes (13), photodiodes / or phototransistors (14) light scanning points are installed on the periphery of the taper tube (11), that is, Said that the tapered tube (11) with the maximum flow calculation range of 1-10L and the effective movement range of the float (12) of 60mm is divided into 30 equal gratings on average, the scanning distance of each pair of gratings is 2mm, and the flow rate corresponding to each pair of gratings The scale is 0.2L, so the measurement error value does not exceed ±2.0%.

[0044] 2, get a set of standard flowmeter, precision grade 1, oxygen input inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com