Automatic temperature-control and rolling-control device for reversible type rolling mill

An automatic and rolling mill technology, applied in the direction of rolling force/roll gap control, temperature control, etc., can solve the problems of unmeasured steel billet performance, no real-time record, unfavorable steel plate quality, etc., achieve strong versatility, improve process control accuracy, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] Example: Automatic temperature control and rolling device for four-high rolling mill in stainless hot rolling mill

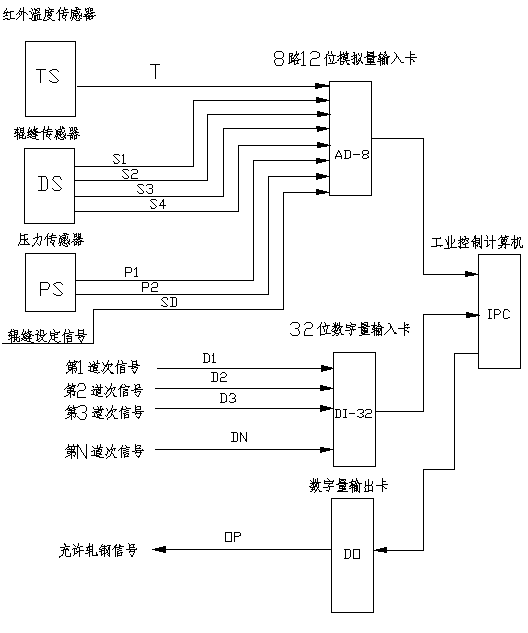

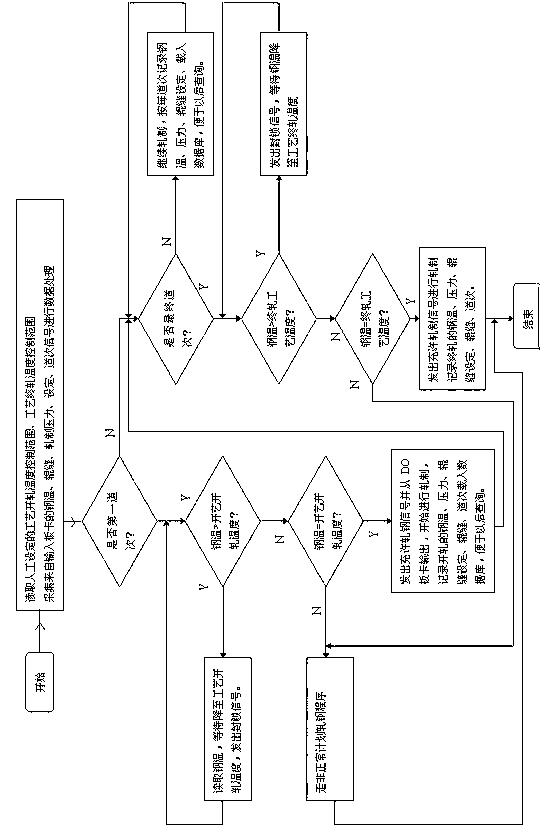

[0034] The four-high rolling mill of Taiyuan Stainless Steel Hot Rolling Plant is a reversible medium-plate rolling mill. In production, a large number of steel types that need to be controlled by temperature and rolling are required to be rolled to meet their special performance requirements. In the past, manual control methods were used for control. For temperature-controlled rolling, it is difficult to guarantee a high level and high control precision of temperature-controlled rolling due to the differences in the methods of each person. Moreover, since there is no real-time record, once a quality problem is found in the future, it is difficult to find the cause in the controlled rolling process or personal operation. To this end, a temperature-controlled rolling device is used to sample the steel temperature, rolling pressure, rolling reduction, reduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com