Patents

Literature

46results about How to "High process control precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

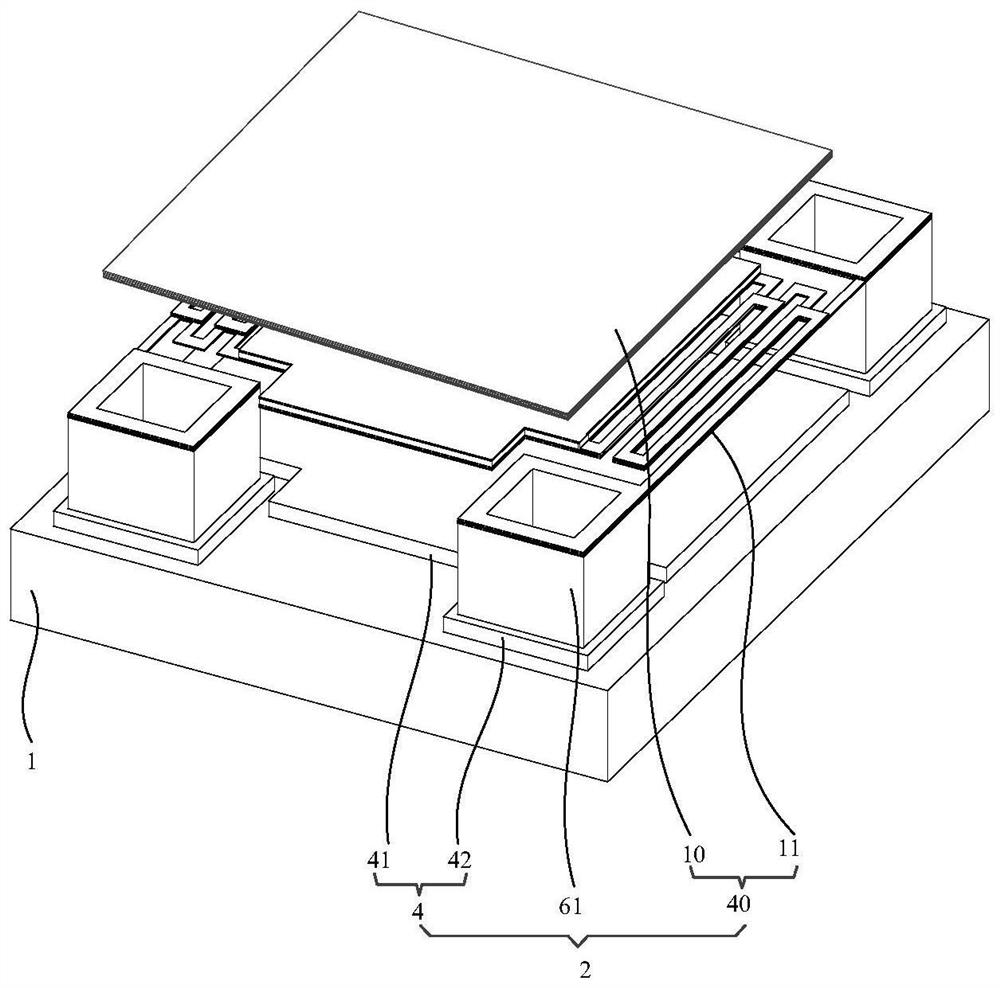

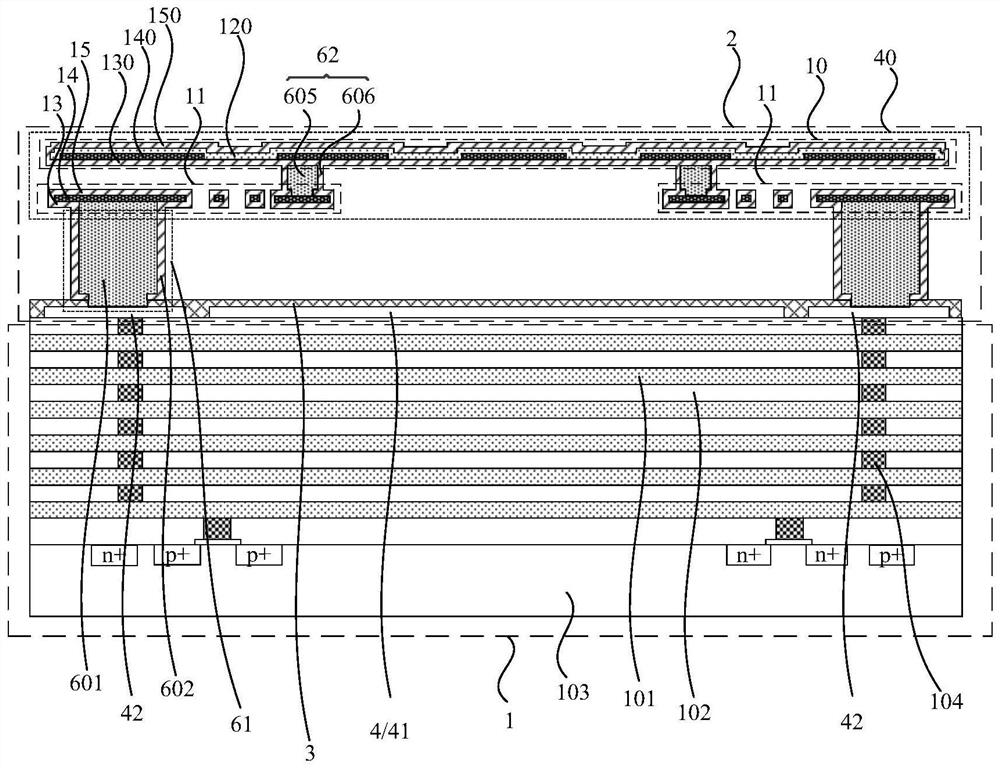

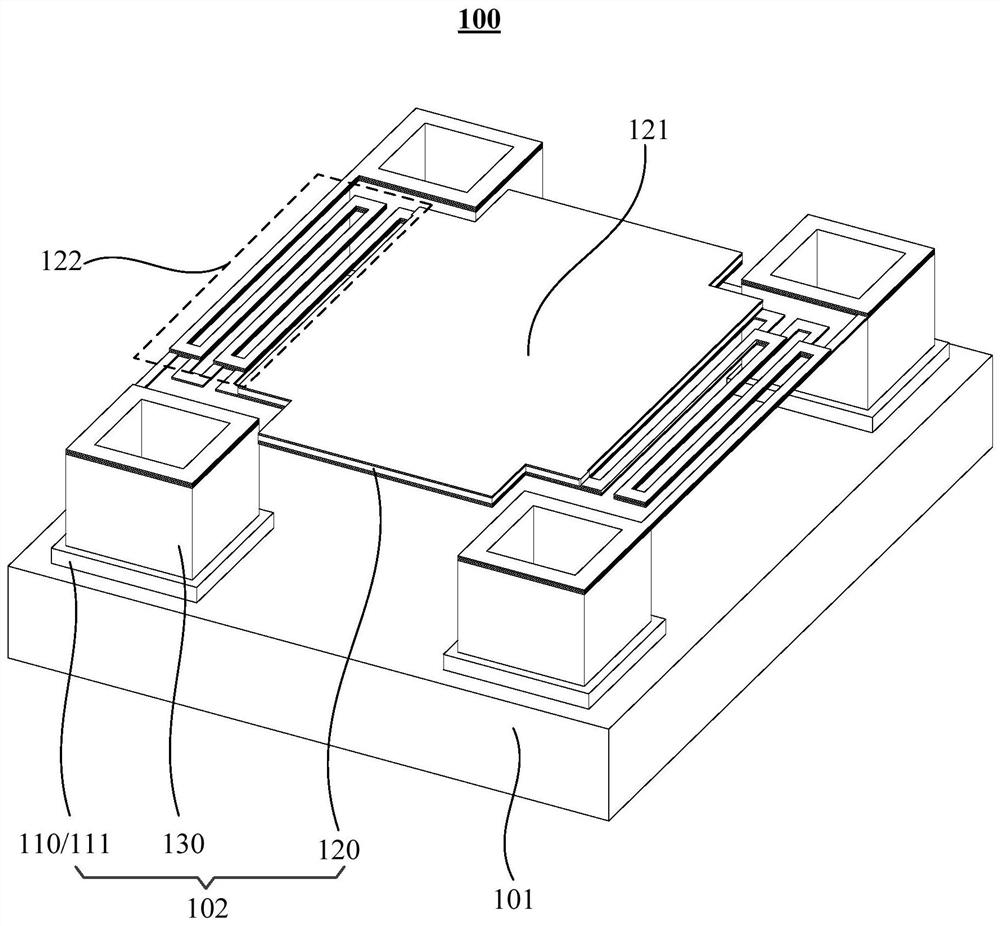

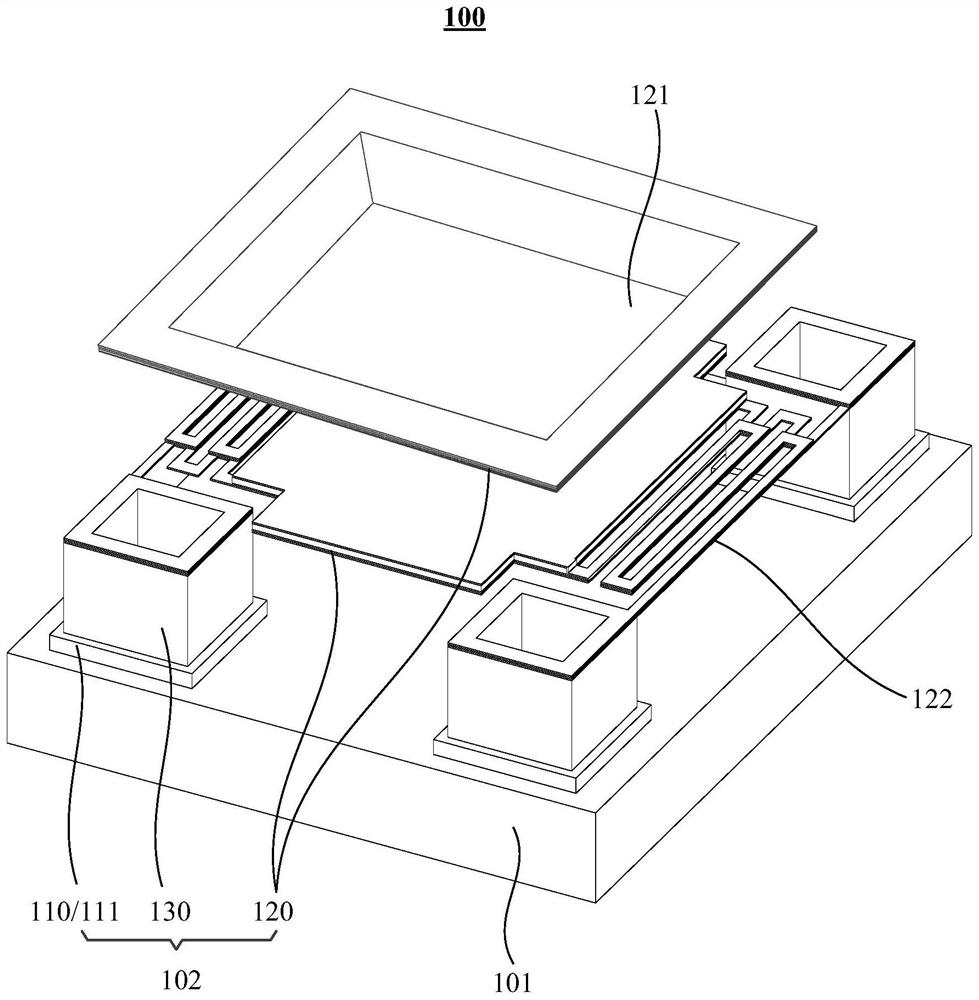

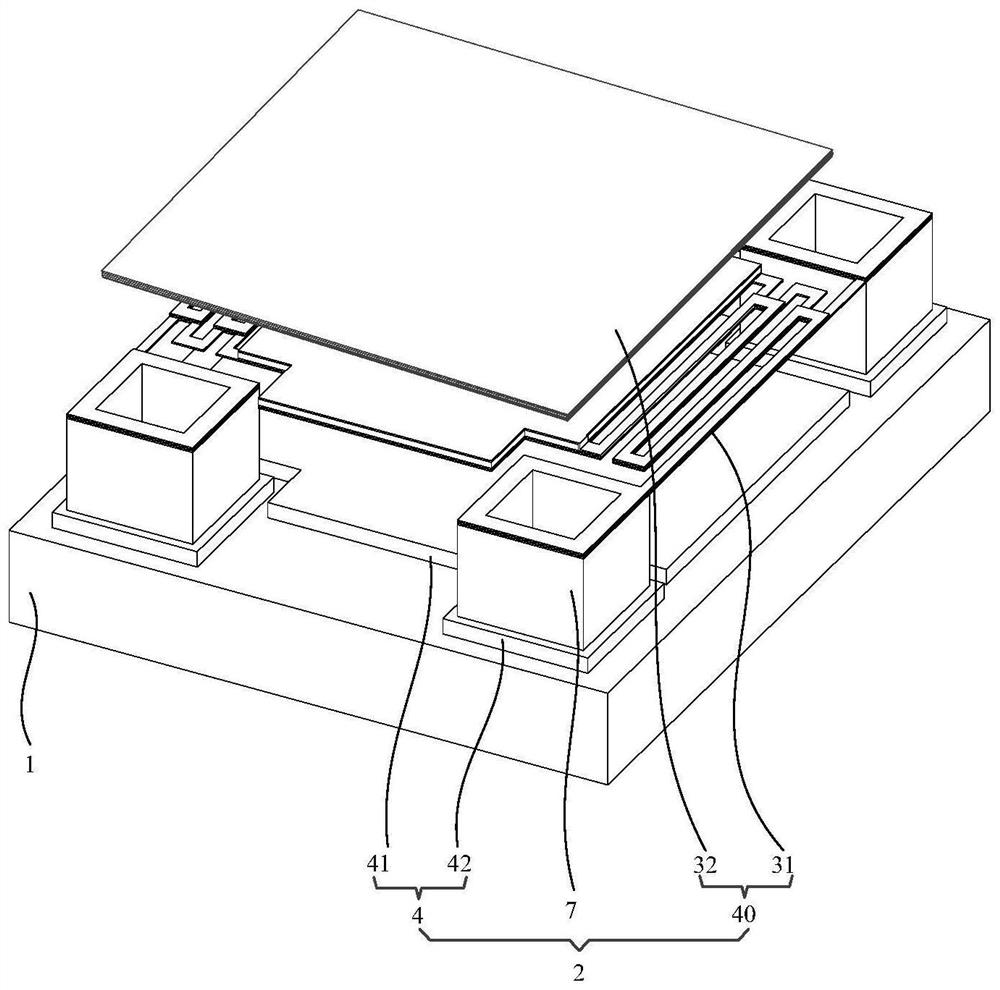

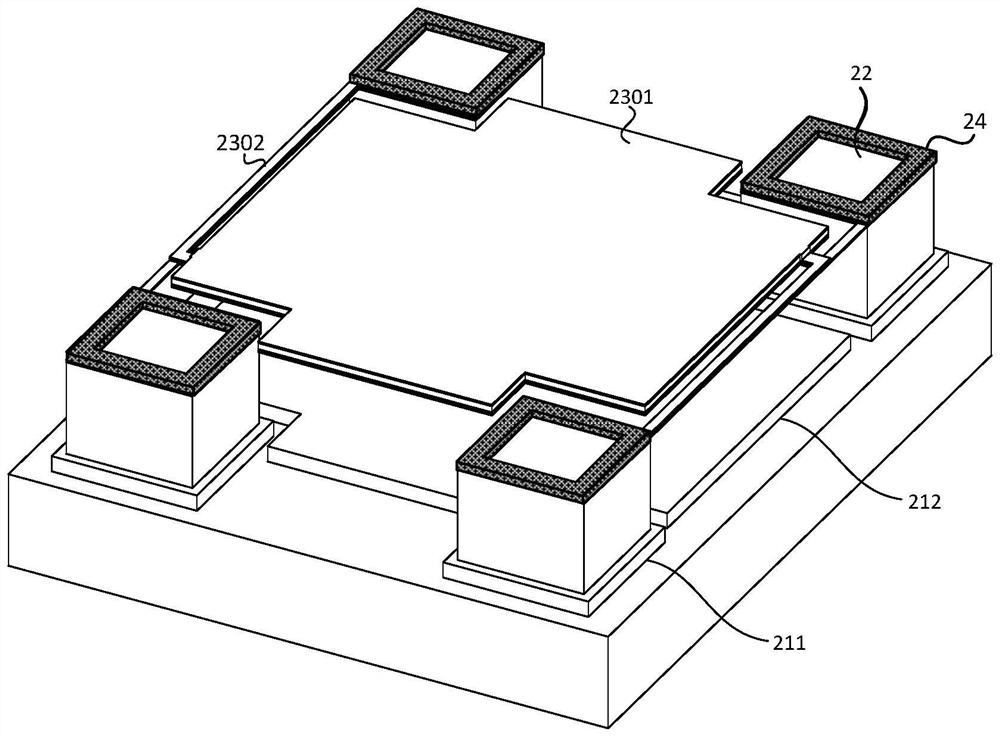

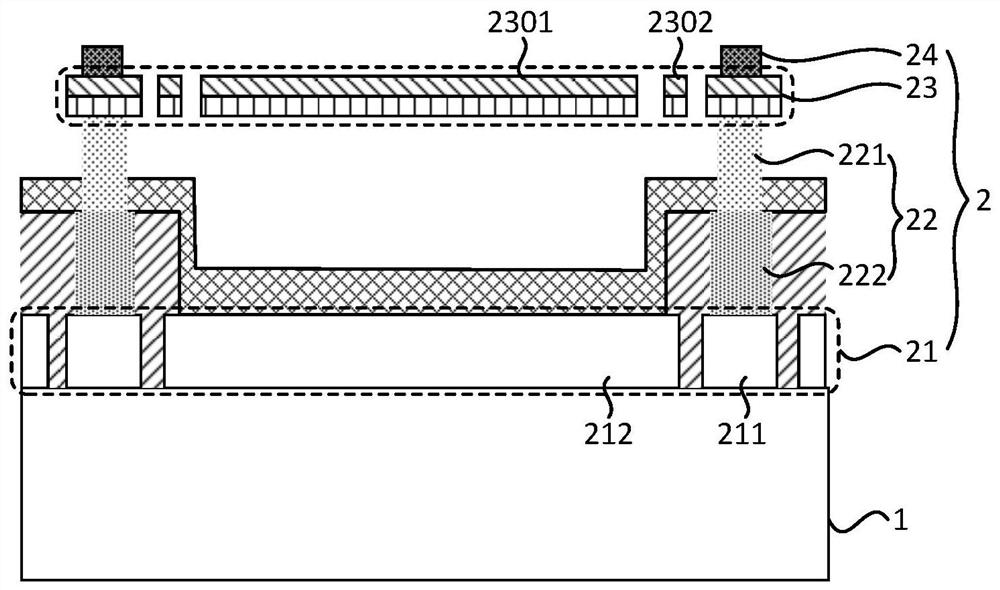

Infrared detector with multi-layer structure based on CMOS (Complementary Metal Oxide Semiconductor) process

ActiveCN113432725AReduce shipping costsReduce riskFinal product manufacturePyrometry using electric radation detectorsIr detectorOxide semiconductor

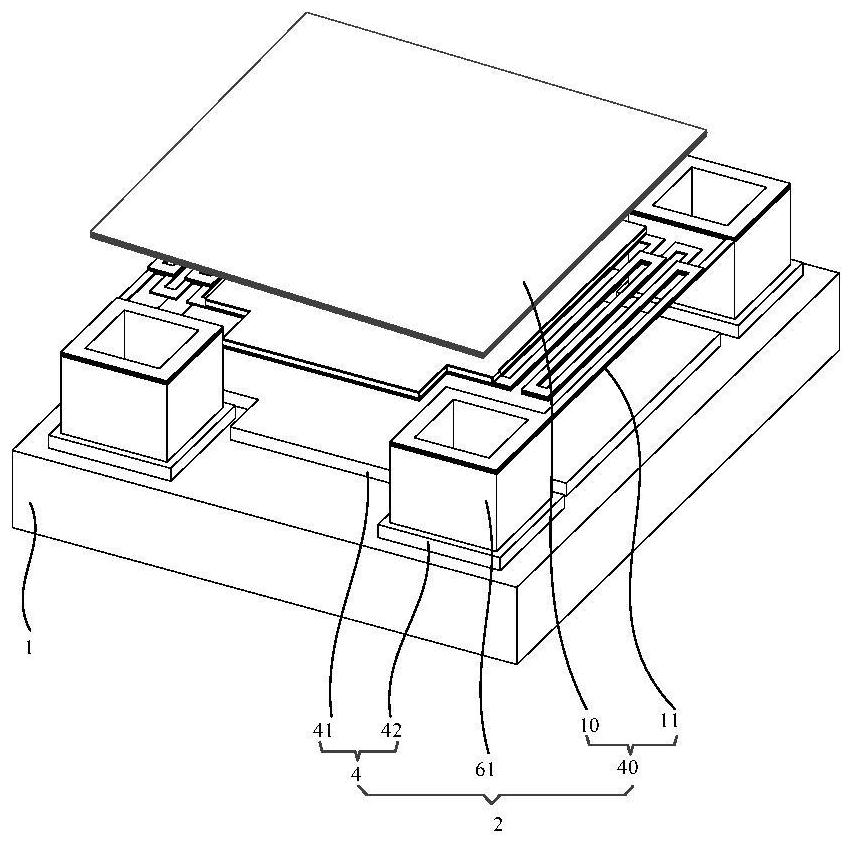

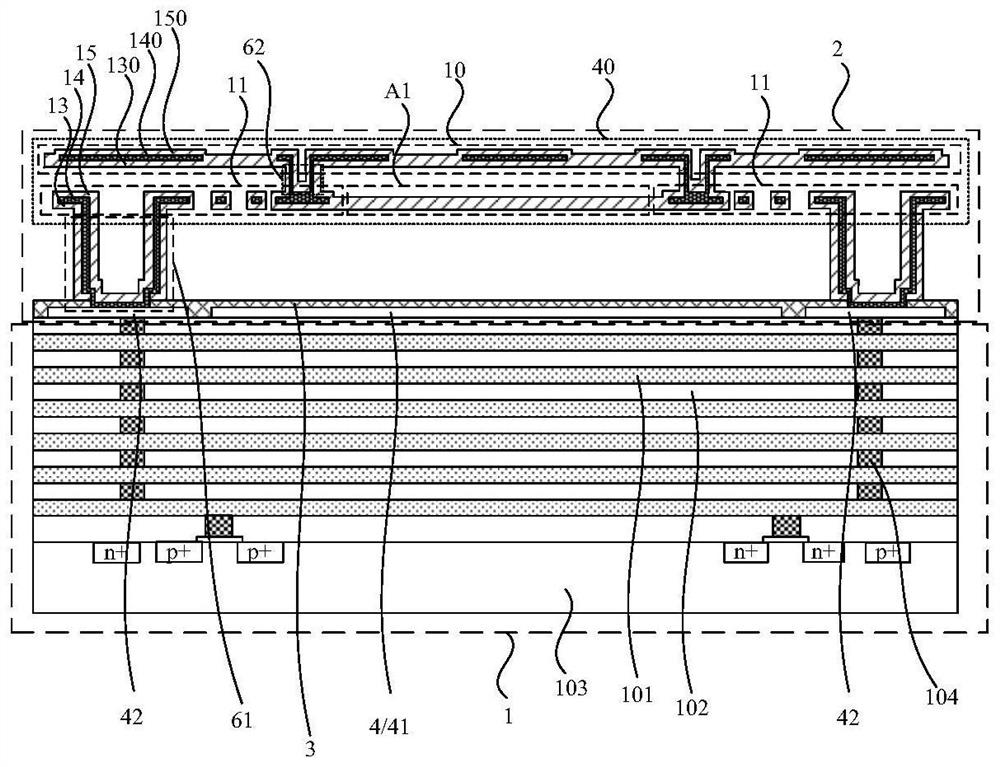

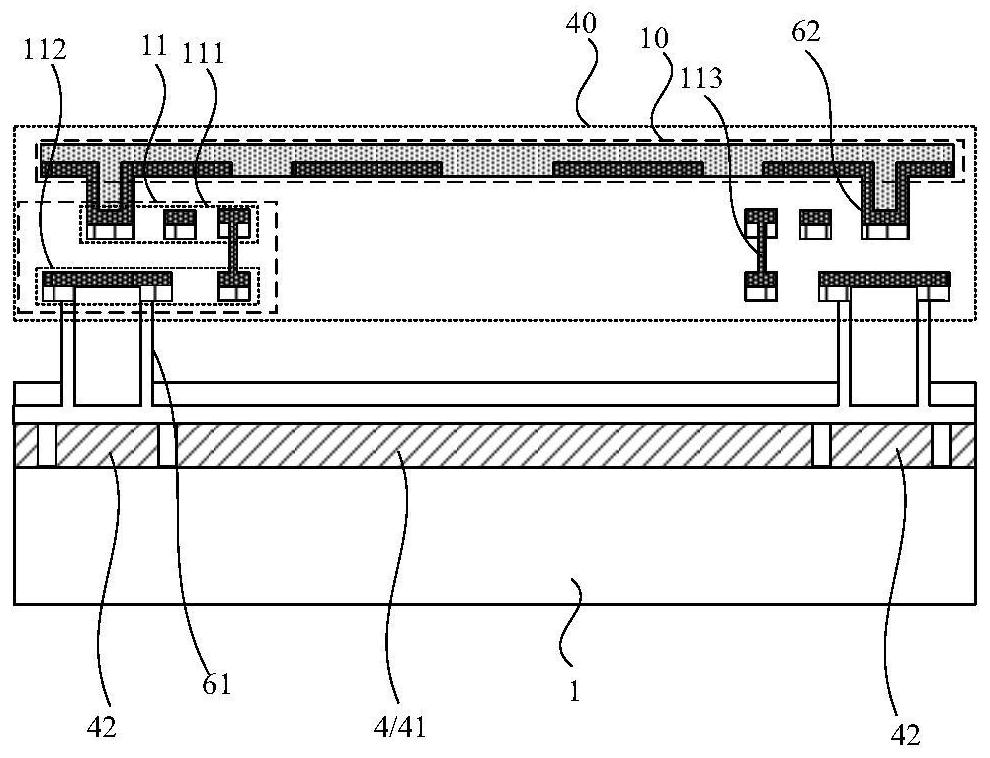

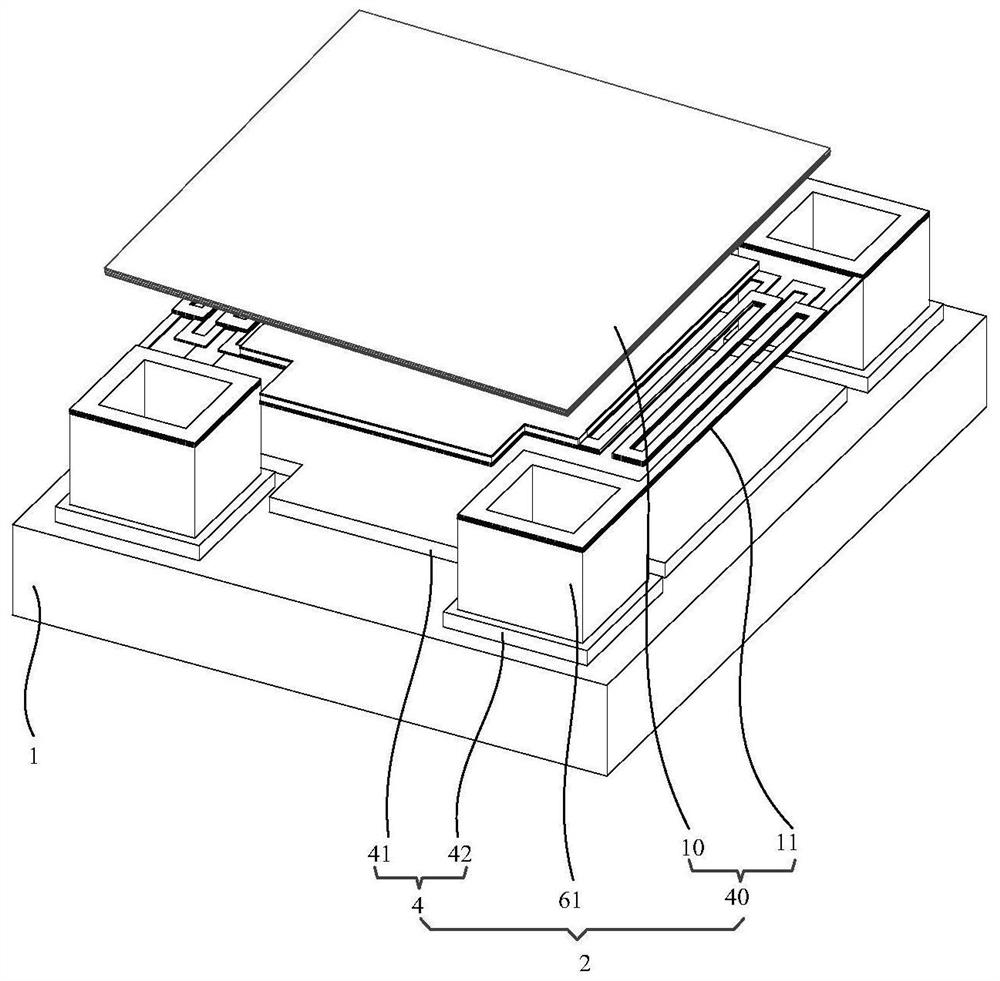

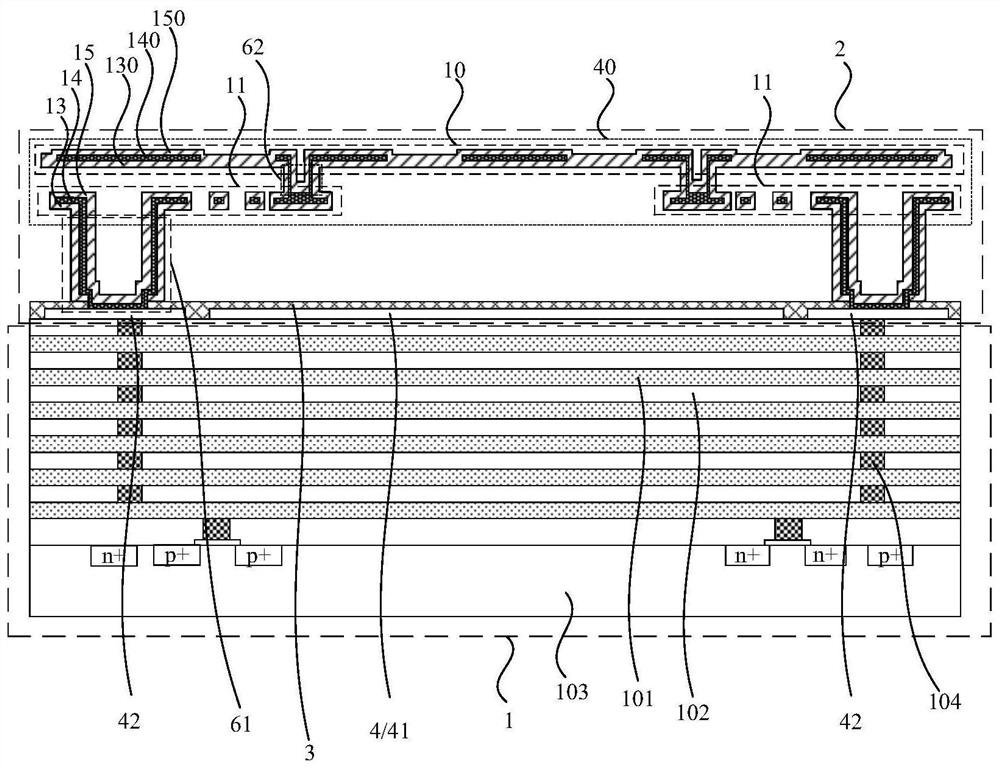

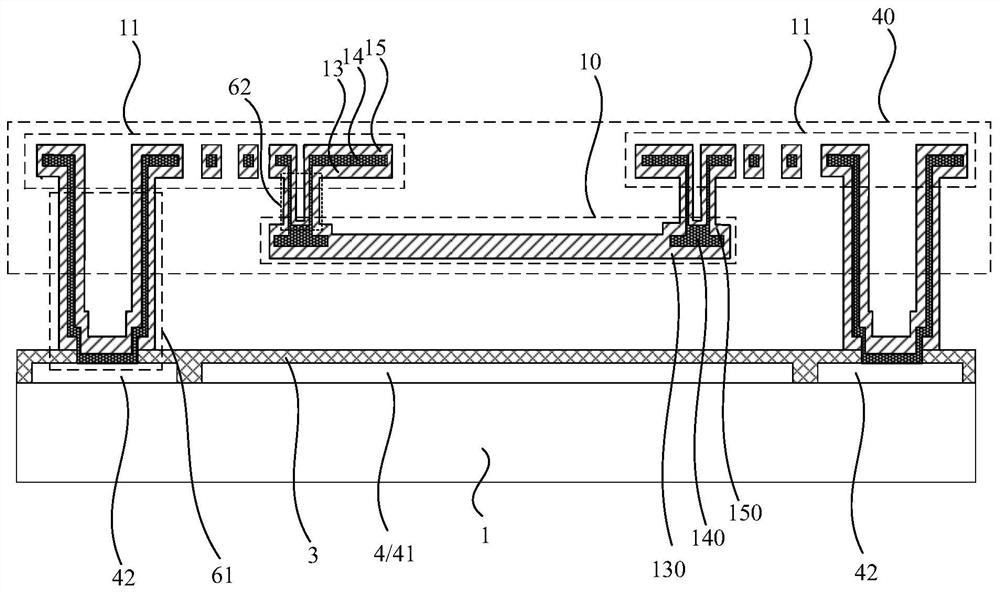

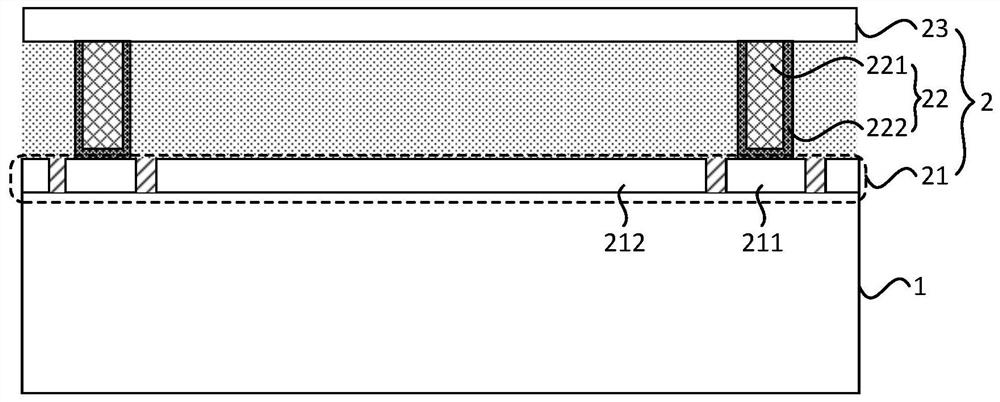

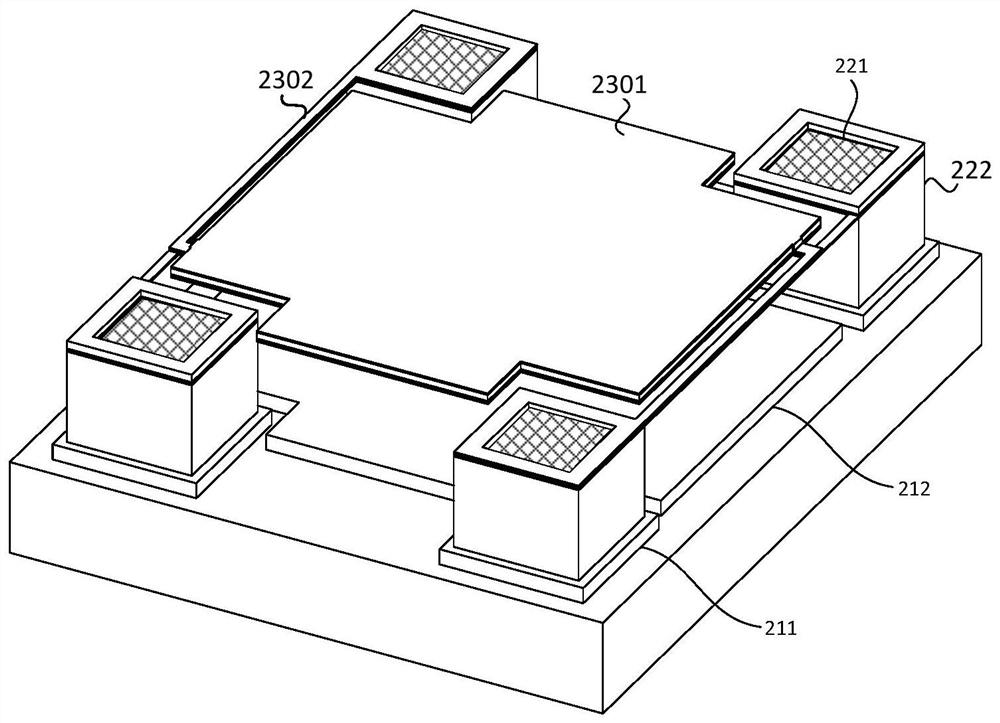

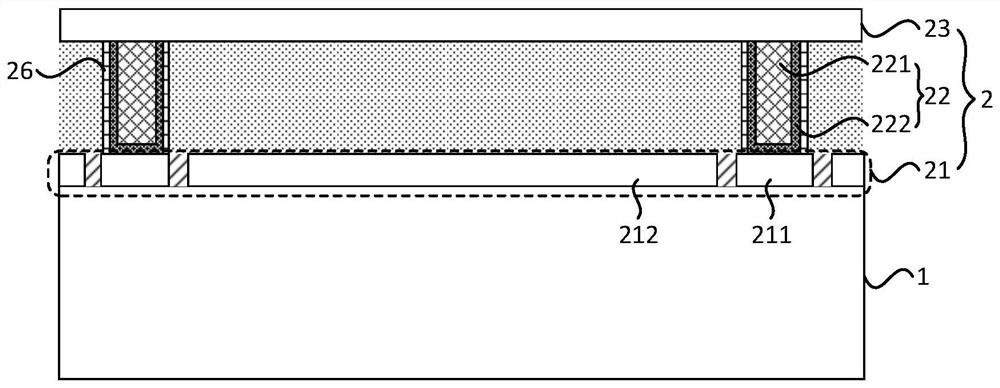

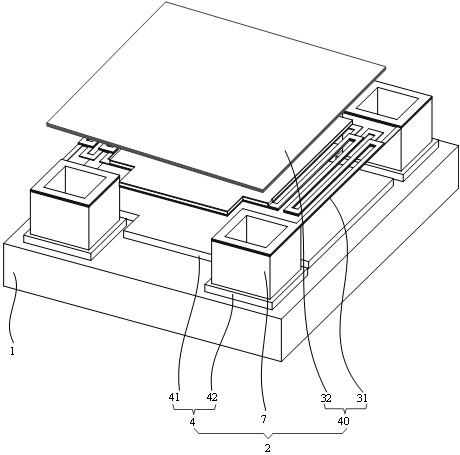

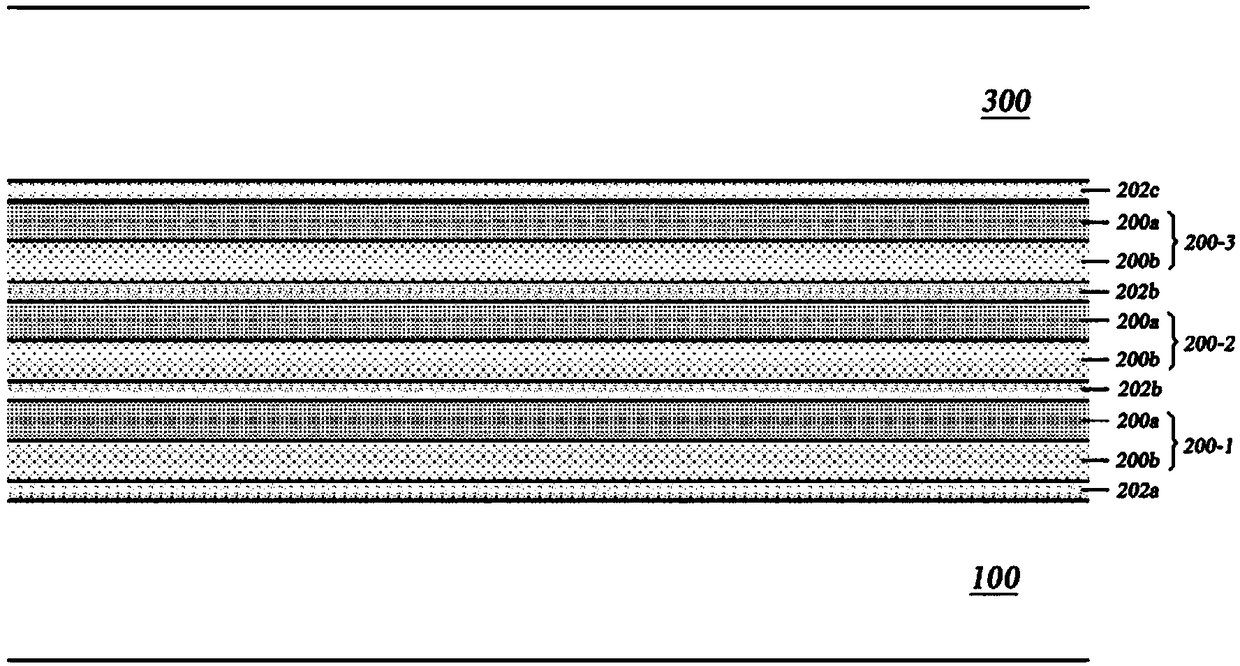

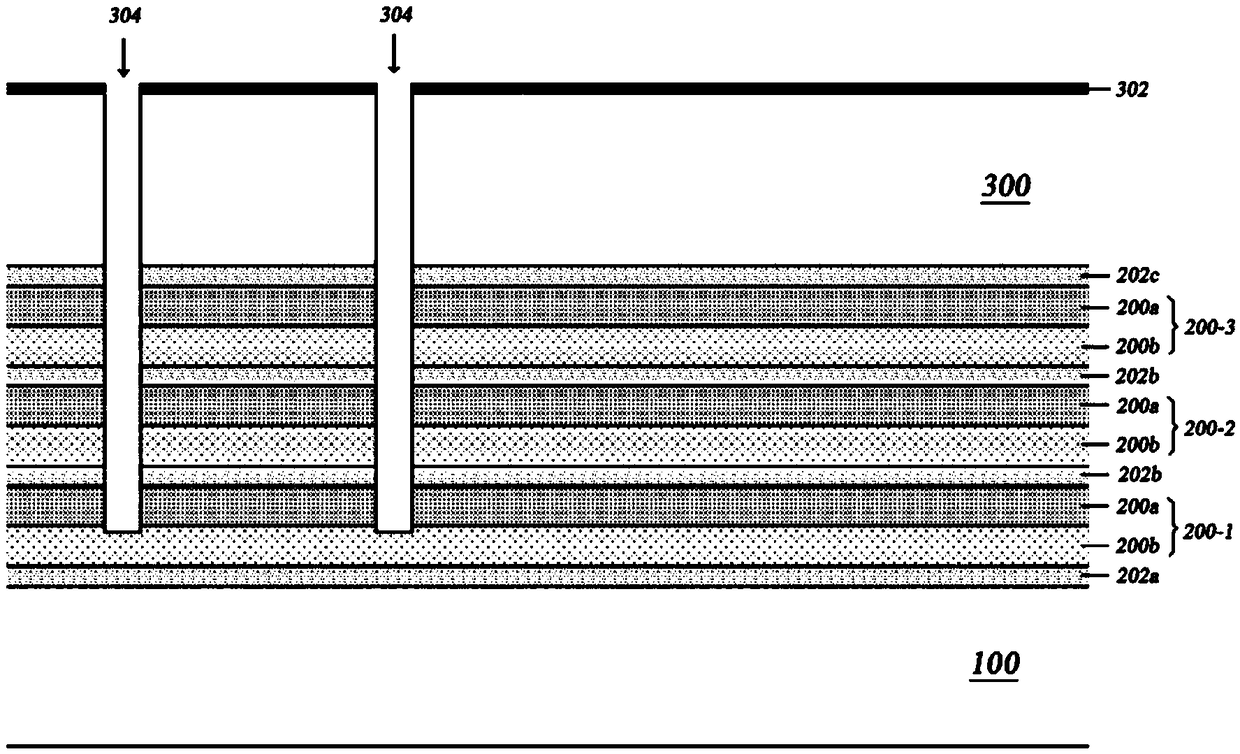

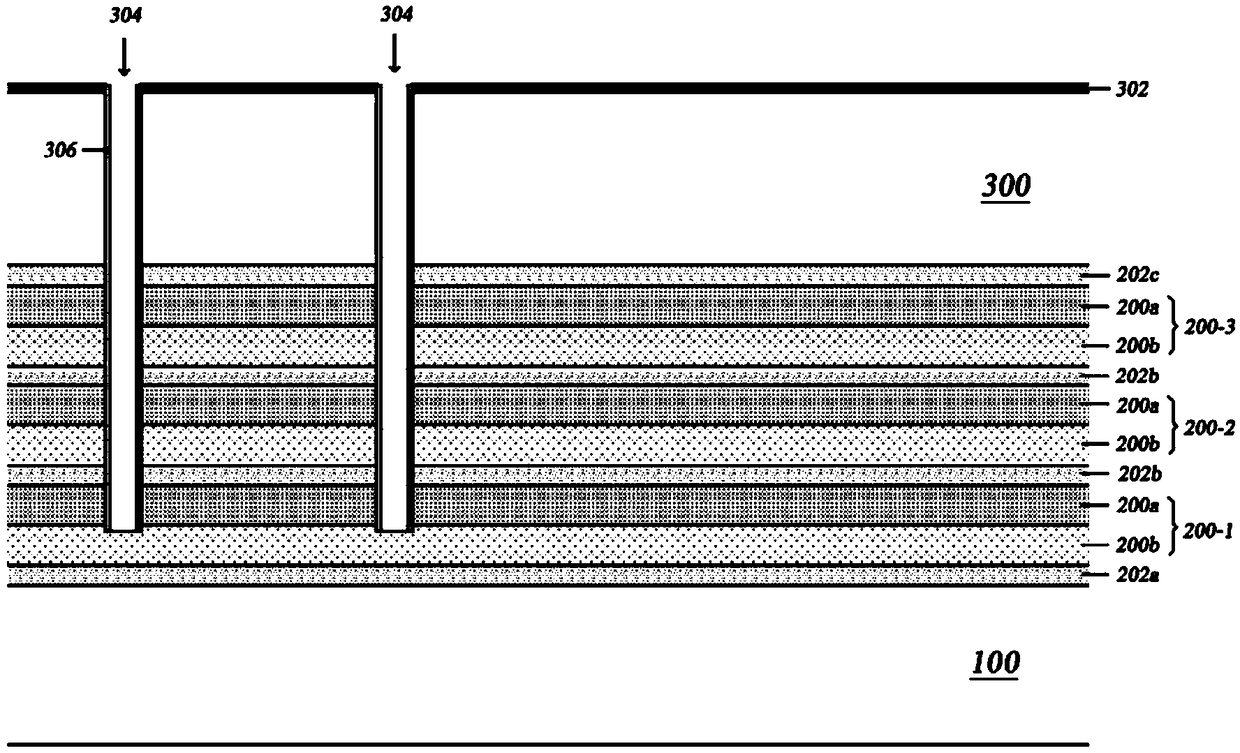

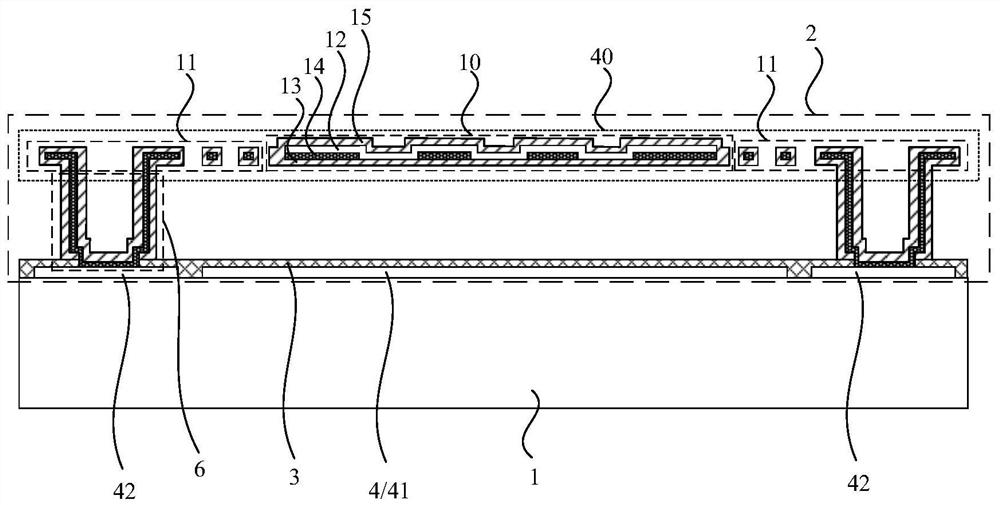

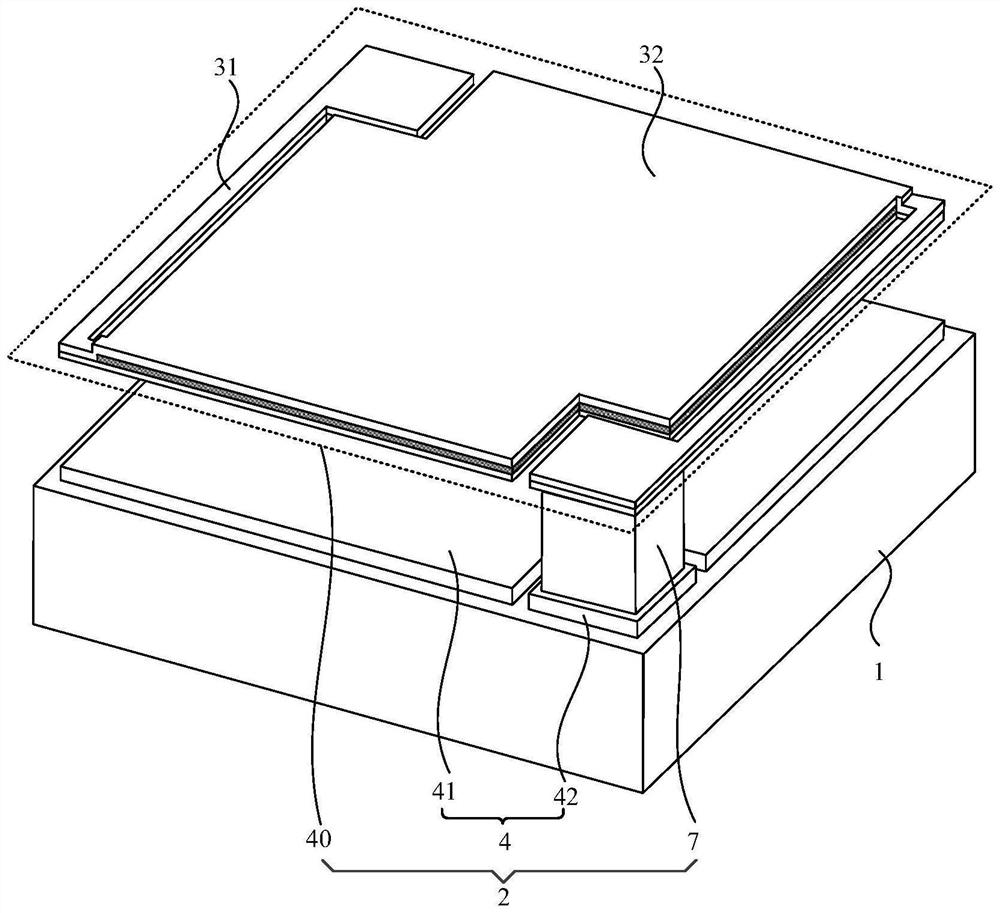

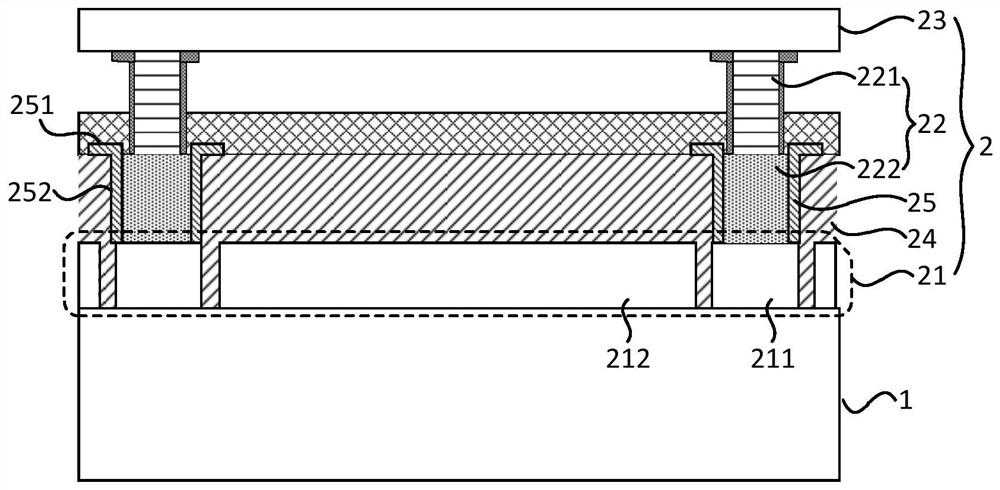

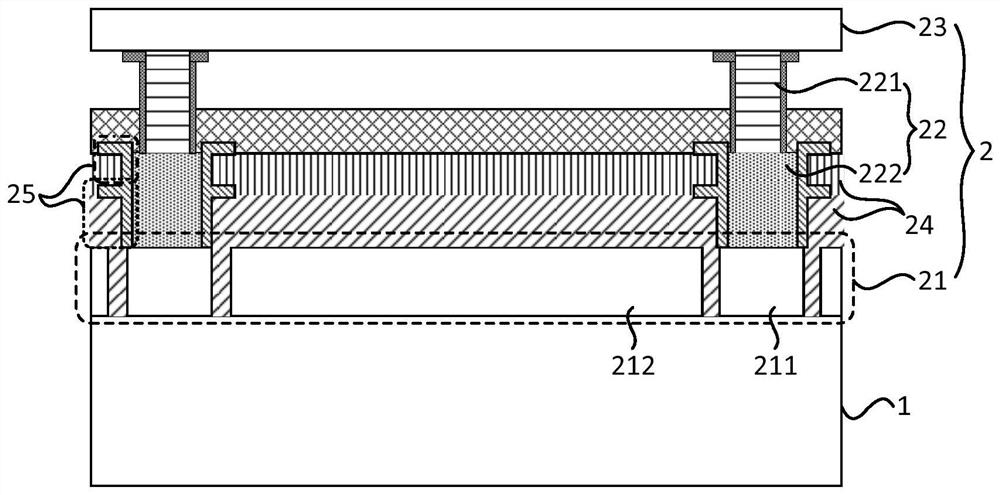

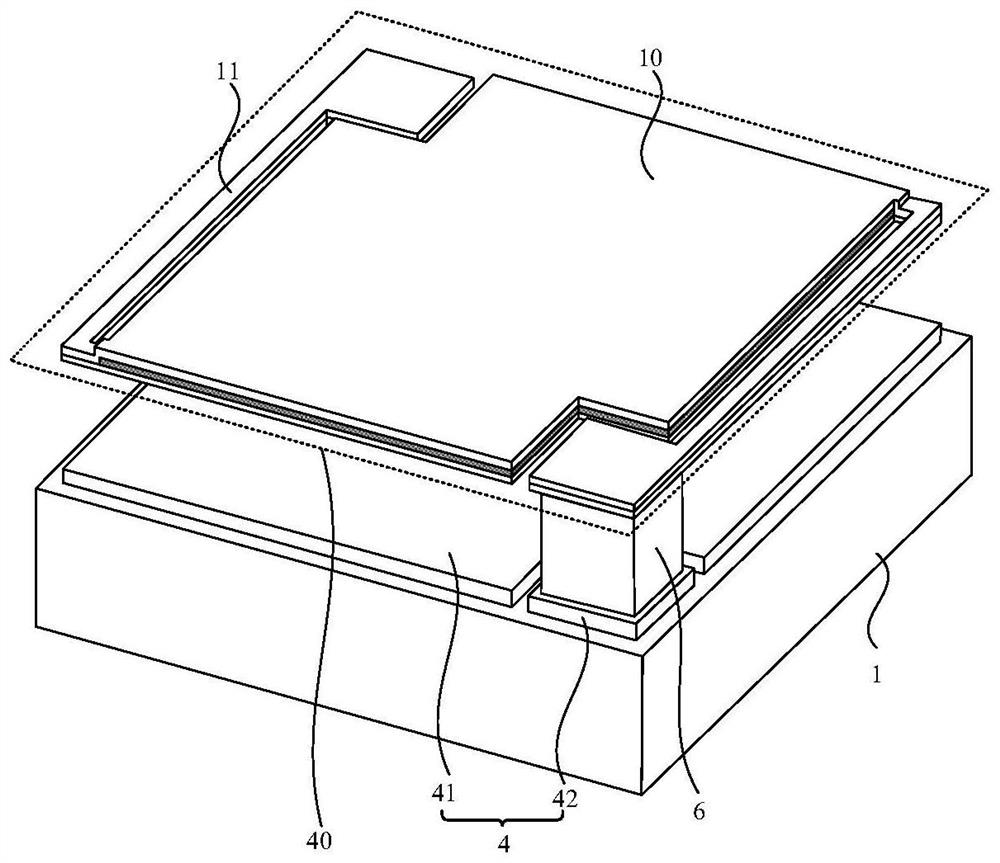

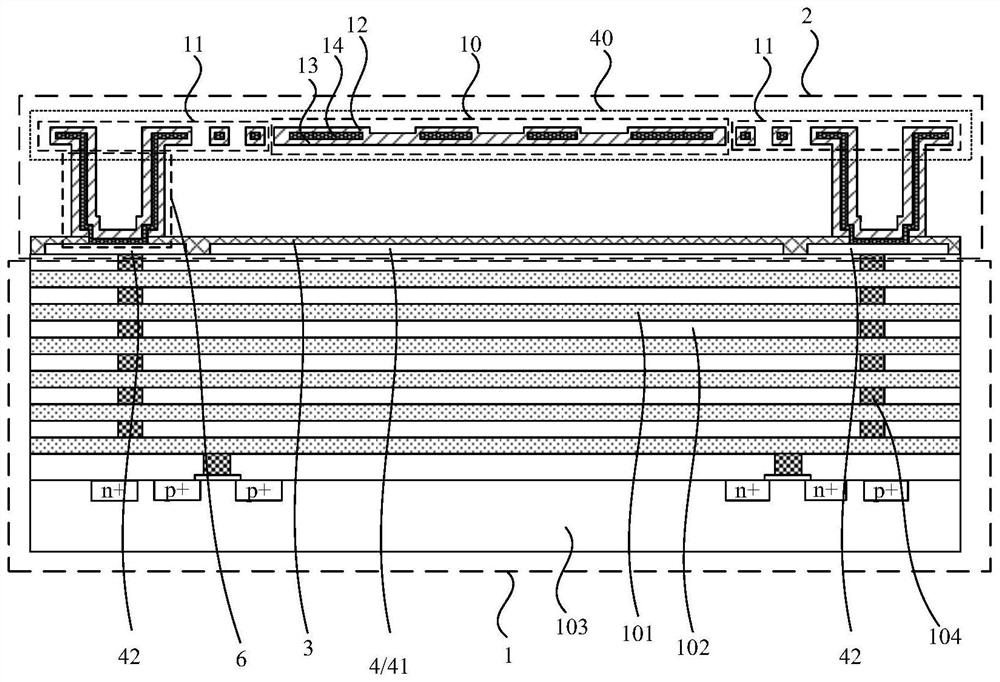

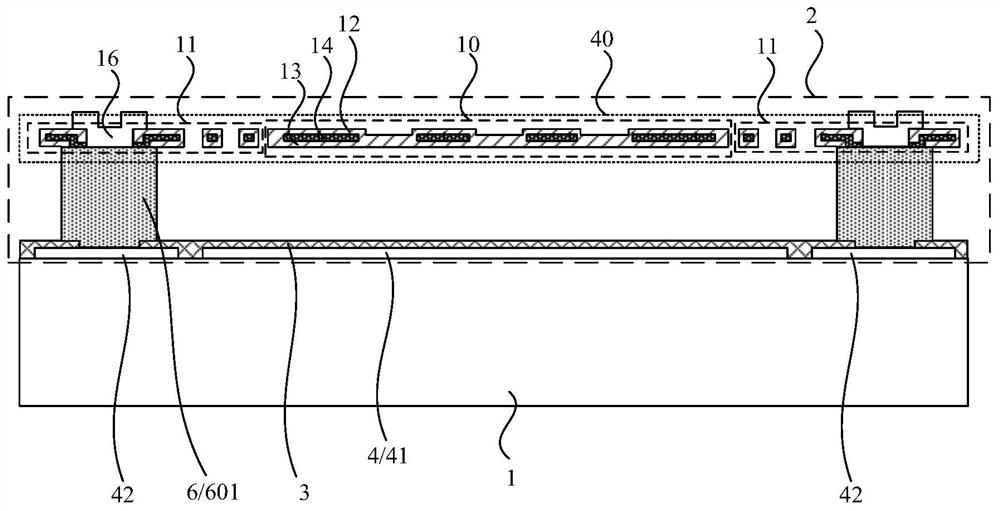

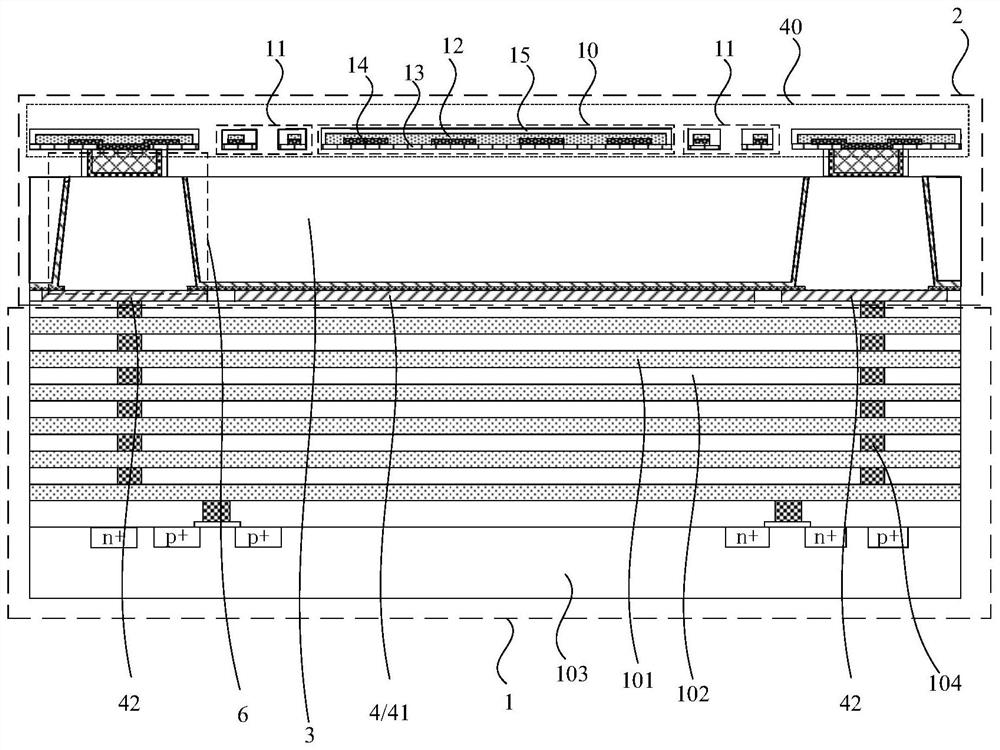

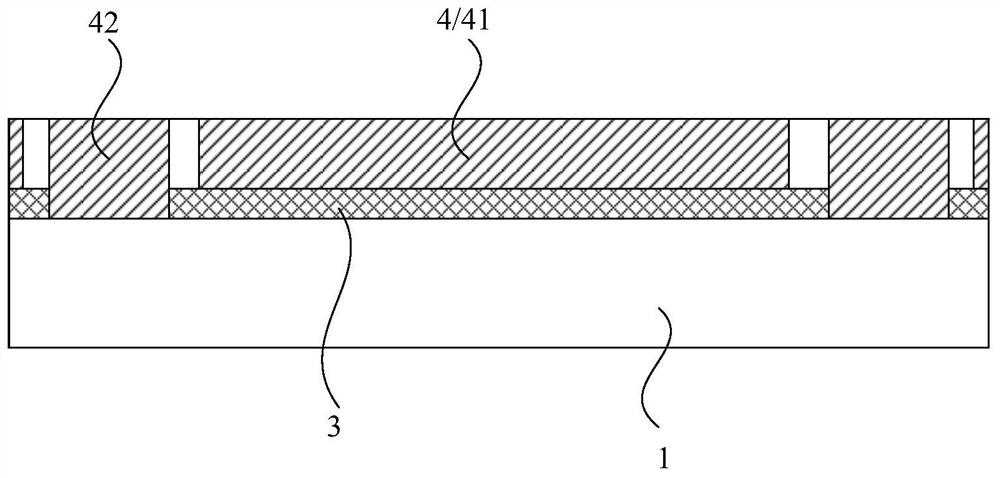

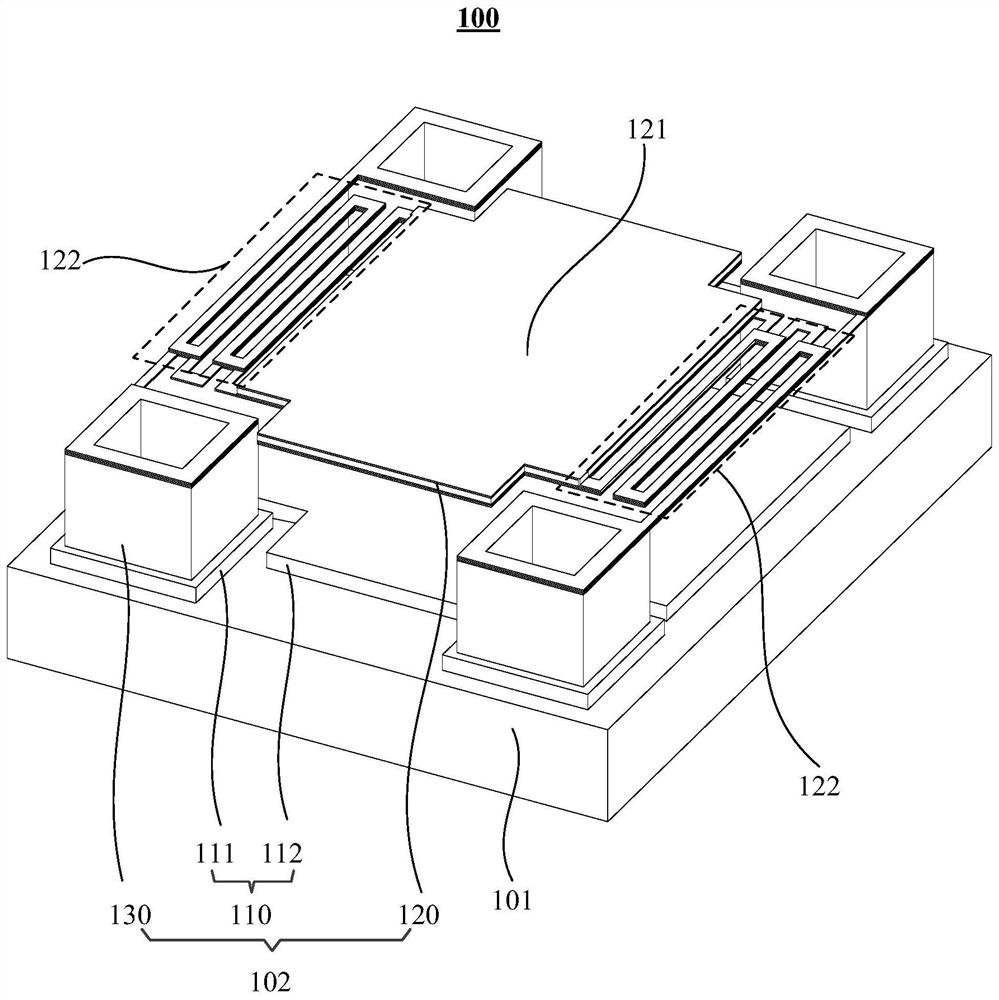

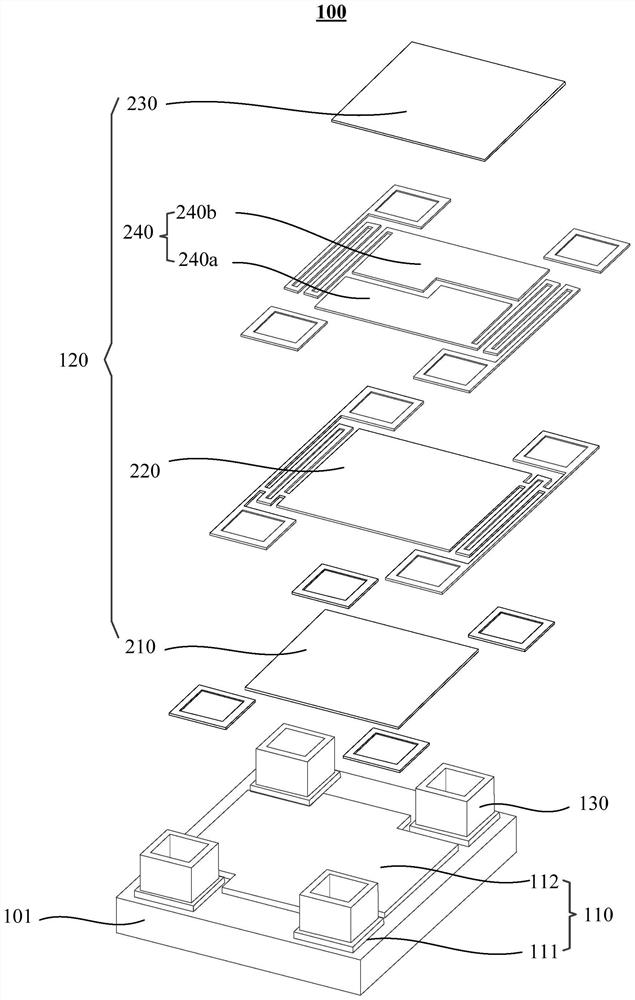

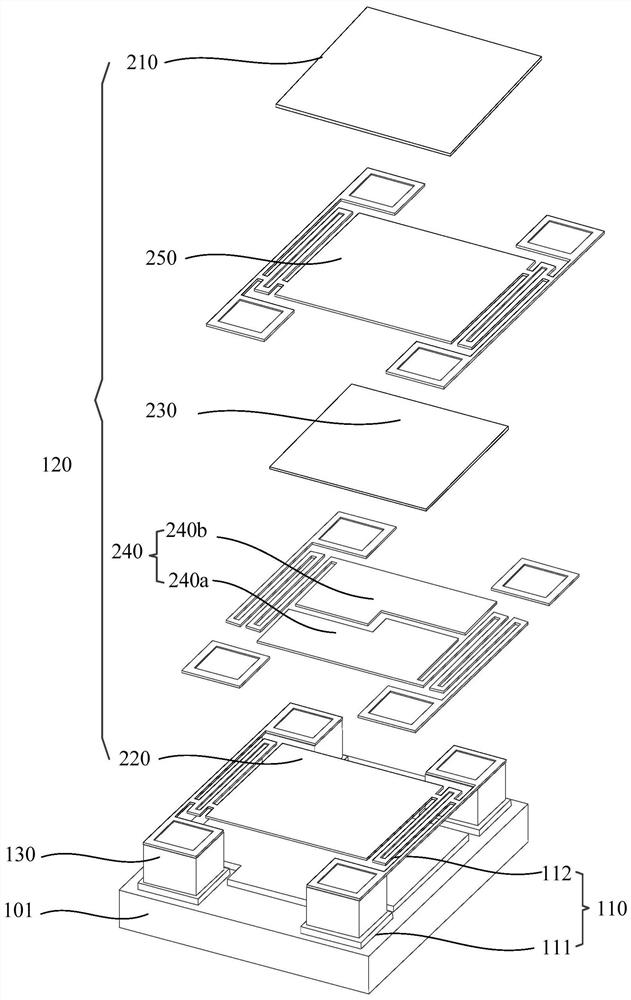

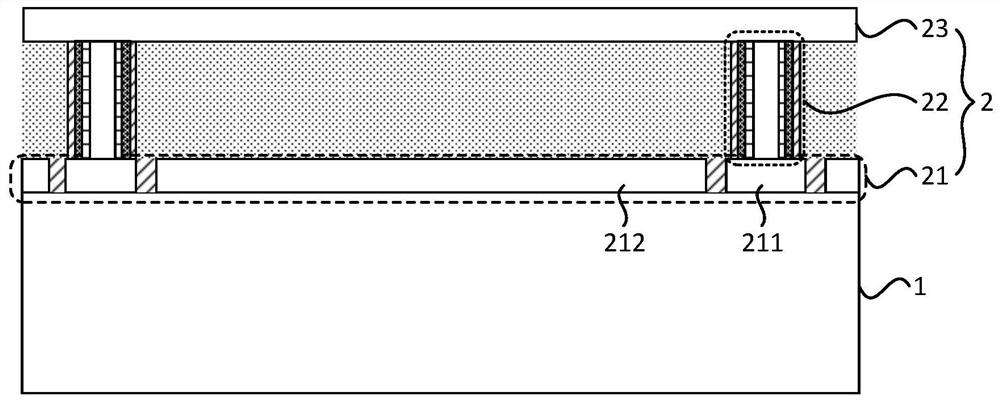

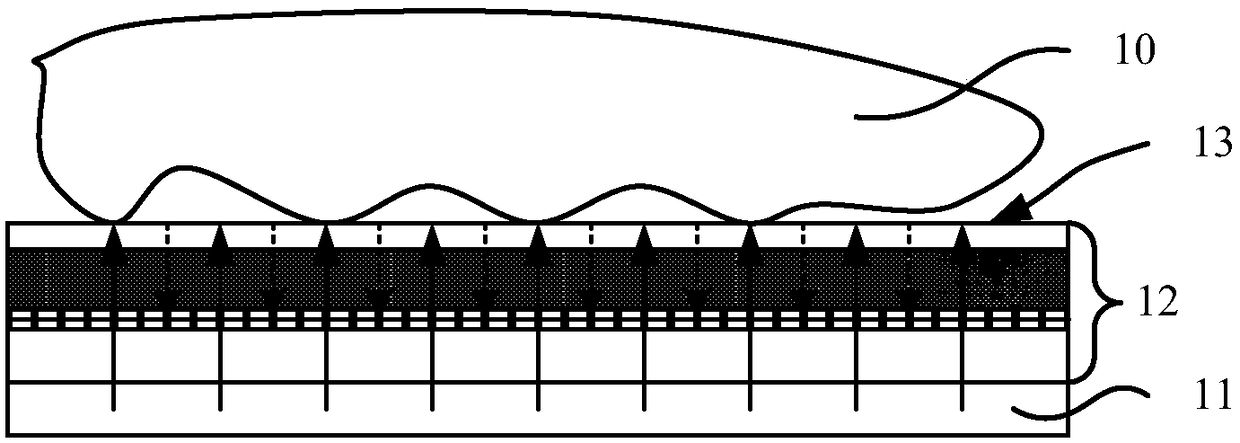

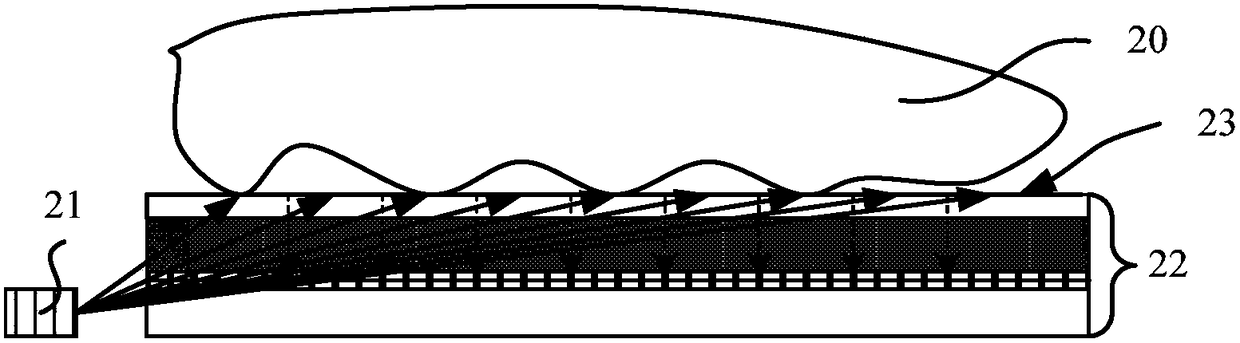

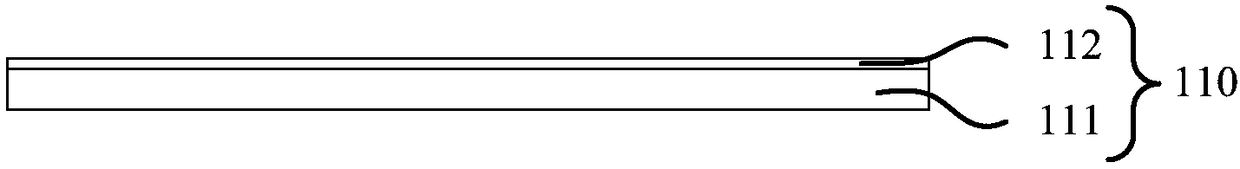

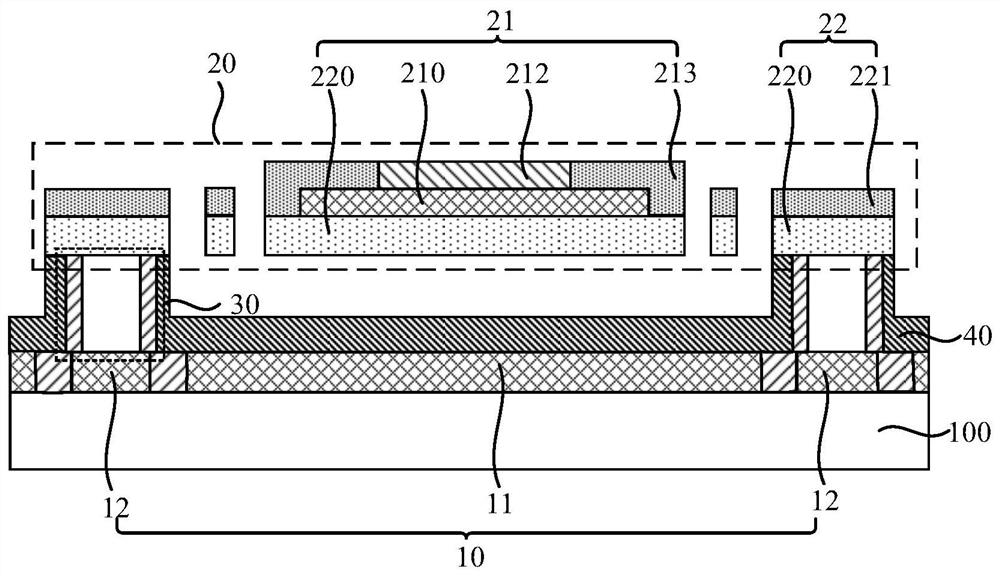

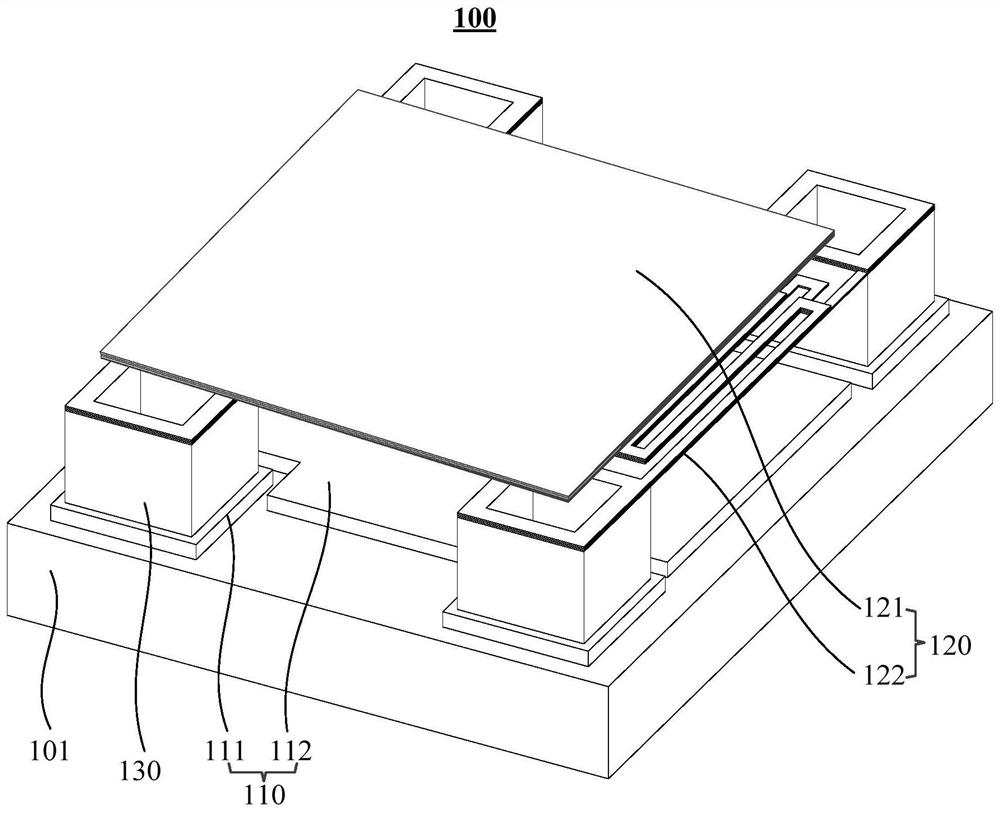

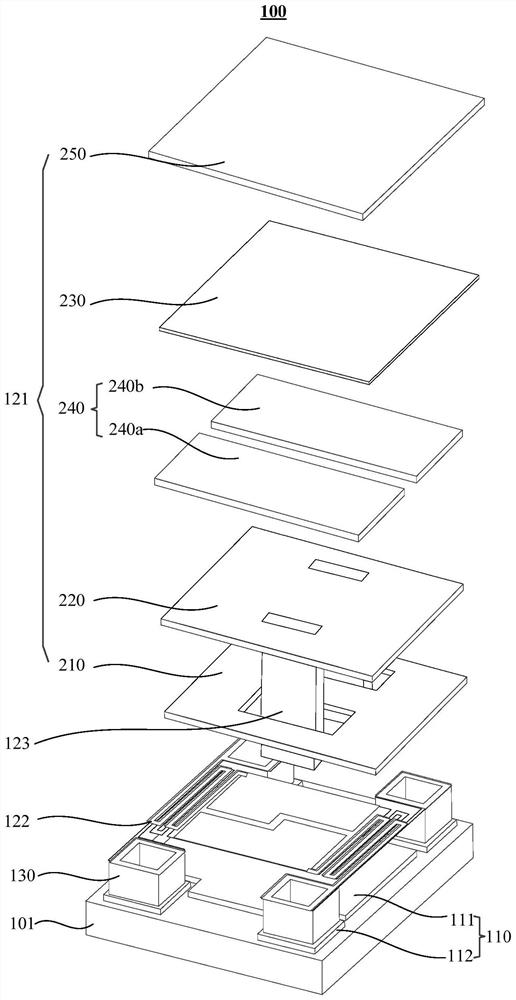

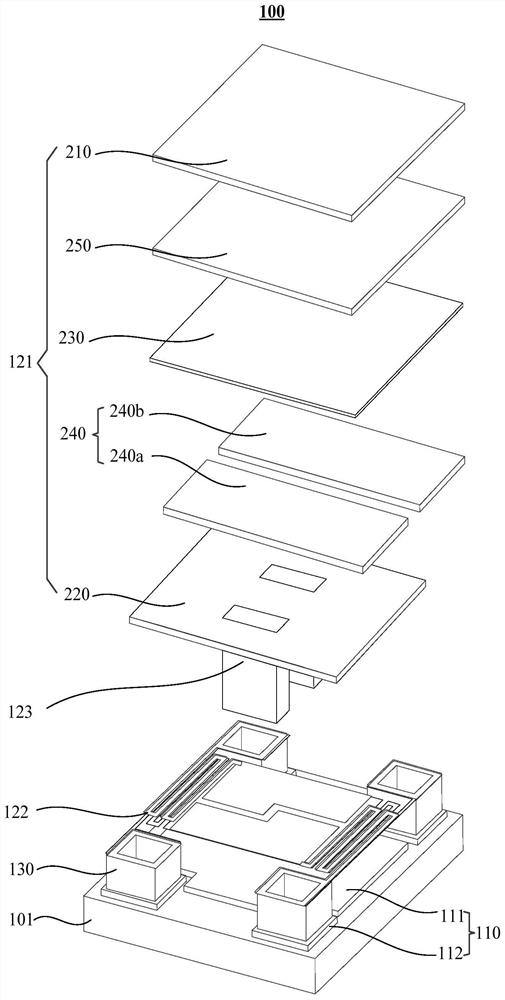

The invention relates to an infrared detector with a multilayer structure based on a CMOS (complementary metal oxide semiconductor) process, a CMOS measuring circuit system and a CMOS infrared sensing structure in the infrared detector are both prepared by using the CMOS process, and the CMOS manufacturing process comprises a metal interconnection process, a through hole process, an IMD (in-mold decoration) process and an RDL (redistribution layer) process; in the infrared detector with the multi-layer structure, a first columnar structure comprises at least one layer of solid columnar structure and / or at least one layer of hollow columnar structure, a second columnar structure comprises at least one layer of solid columnar structure and / or at least one layer of hollow columnar structure, at least one hole-shaped structure is formed in an absorption plate, and the hole-shaped structure at least penetrates through a dielectric layer in the absorption plate; and / or at least one hole-shaped structure is formed on a beam structure. The infrared detector is advantaged in that problems of low performance, low pixel scale, low yield and poor consistency of a traditional MEMS process infrared detector are solved, the planarization degree of the absorption plate is optimized, thermal conductivity of the beam structure is reduced, and the performance of the infrared detector is optimized.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Novel stainless steel negative ion healthcare material and manufacturing technology thereof

InactiveCN105618737AHas health benefitsUnique preparation processTransportation and packagingMetal-working apparatusManufacturing technologyFar infrared

The invention provides a novel stainless steel negative ion healthcare material and a manufacturing technology thereof. The novel stainless steel negative ion healthcare material is machined through components which include, by mass, 2-25 parts of negative ion far infrared mother powder particles, 73-96 parts of fine stainless steel powder and 2 parts of cation exchange powder resin micropowder. The manufacturing technology includes the steps of raw material weighing, rotating mixing, compressing molding and sintering smelting. On the basis of adopting a conventional stainless steel material, a negative ion raw material is added, on the basis that the stainless steel material is reserved as the structural material, the negative ion raw material can release negative ion energy, the healthcare functions of strengthening, adjusting and balance assisting of all the systems of a human body are achieved, in addition, the manufacturing technology is unique, and the technology control precision is high.

Owner:FOSHAN SUCCESS JEWELRY CO LTD

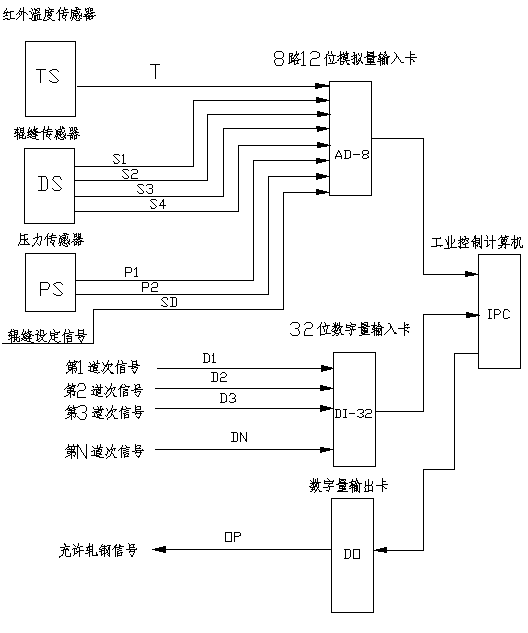

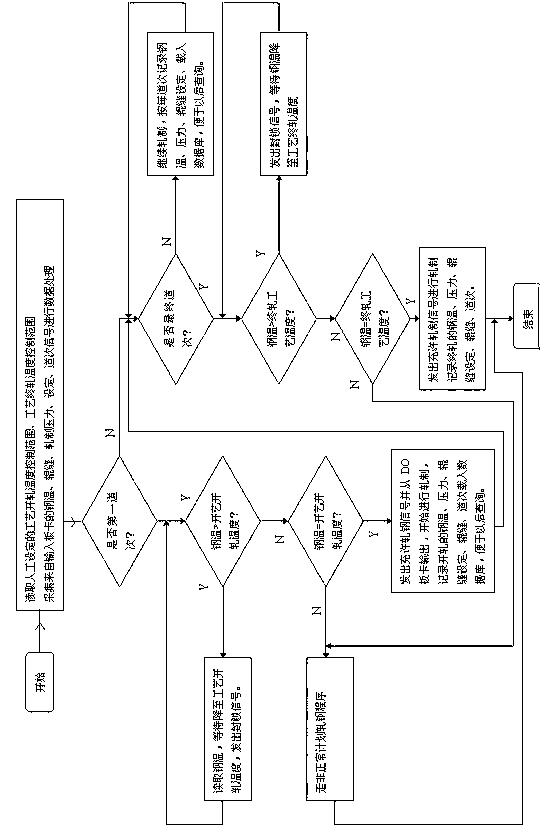

Automatic temperature-control and rolling-control device for reversible type rolling mill

ActiveCN103331309AHigh process control precisionRealize the automation of temperature control and rollingRoll force/gap control deviceTemperature control deviceTemperature controlSheet steel

An automatic temperature-control and rolling-control device for a reversible type rolling mill belongs to the field of metallurgy and comprises a temperature sensor, a displacement sensor, a pressure sensor, an industrial control computer, an analogue value input card, a digital quantity input card and a digital quantity output card, wherein the output of the temperature sensor, the output of the displacement sensor and the output of the pressure sensor are all connected with the input of the analogue value input card; the output of the analogue value input card is connected with the input of the industrial control computer; the output of the industrial control computer is connected with the input of the digital quantity output card; the output of the digital quantity output card is connected with a control system of the rolling mill; the output of a pass signal processor of the rolling mill is connected with the input of the digital quantity input card; the output of the digital quantity input card is connected with the input of the industrial control computer. According to the invention, the control precision of the technology that the rolling mill performs the temperature control and rolling control to steel plates is improved, and the automation of the temperature control and rolling control of the steel plates is realized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

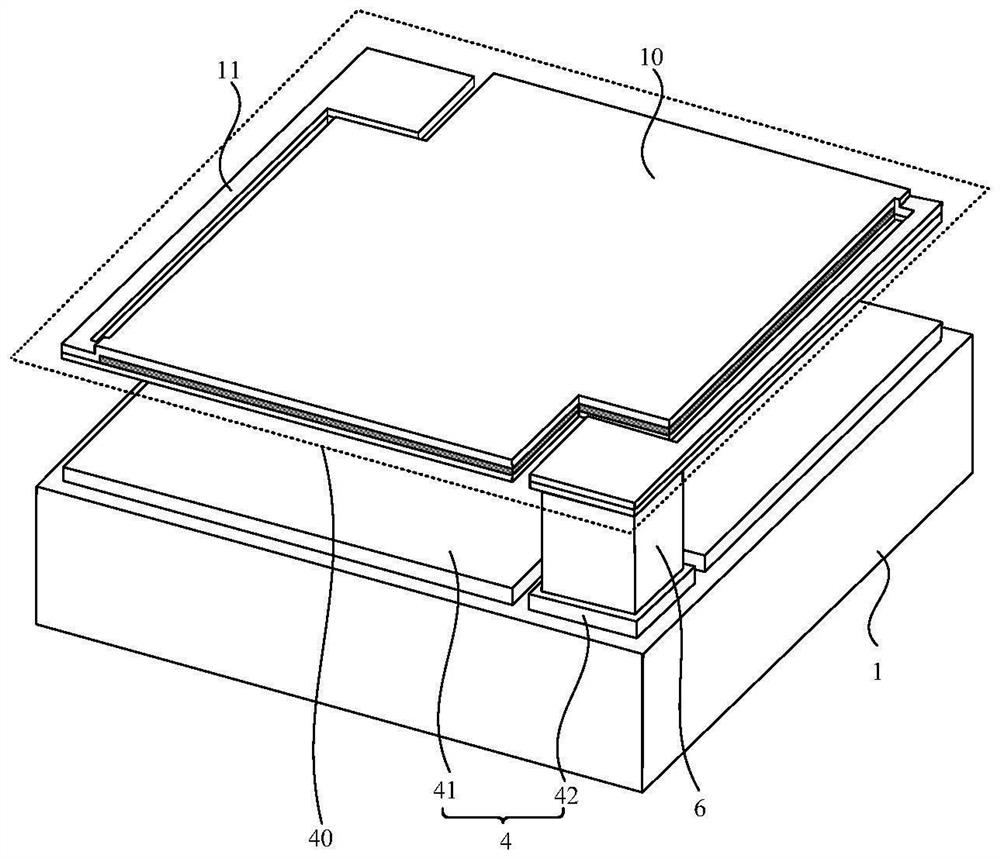

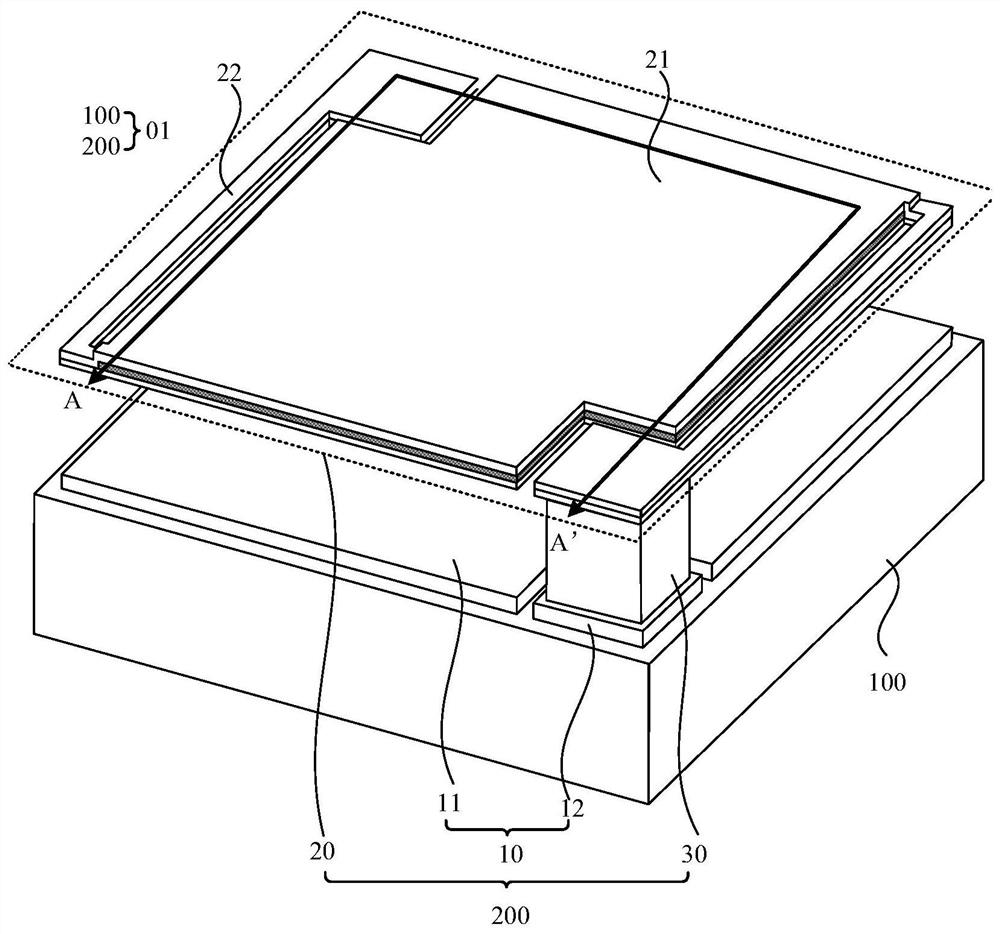

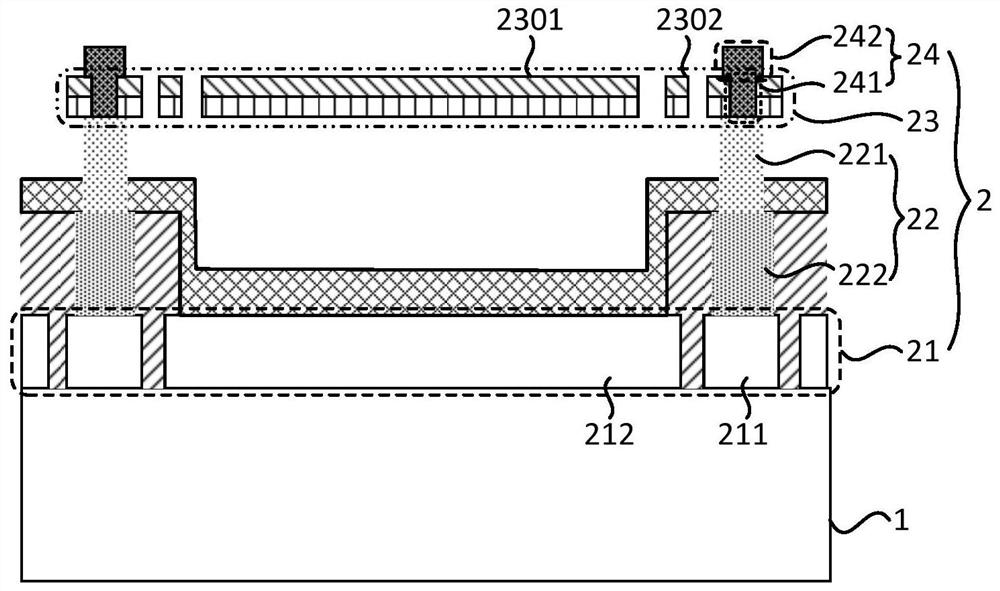

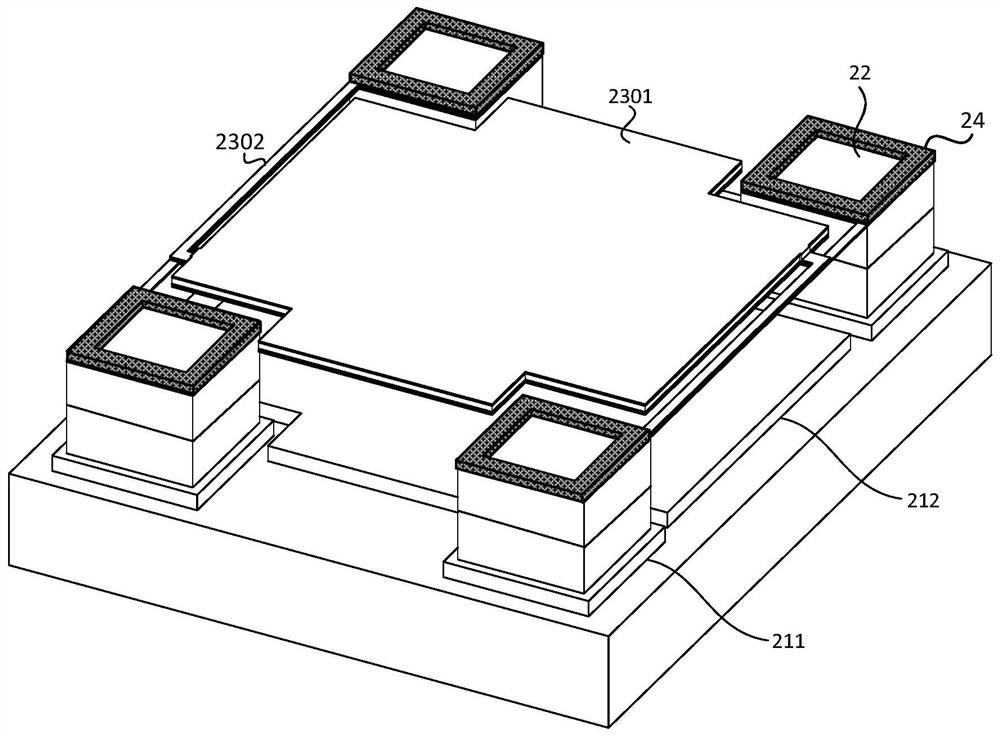

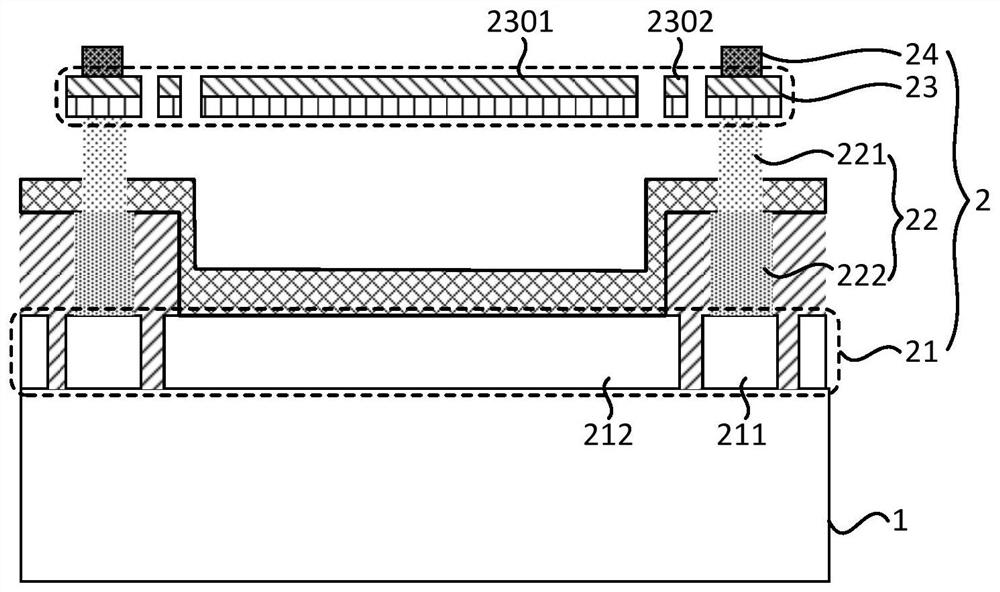

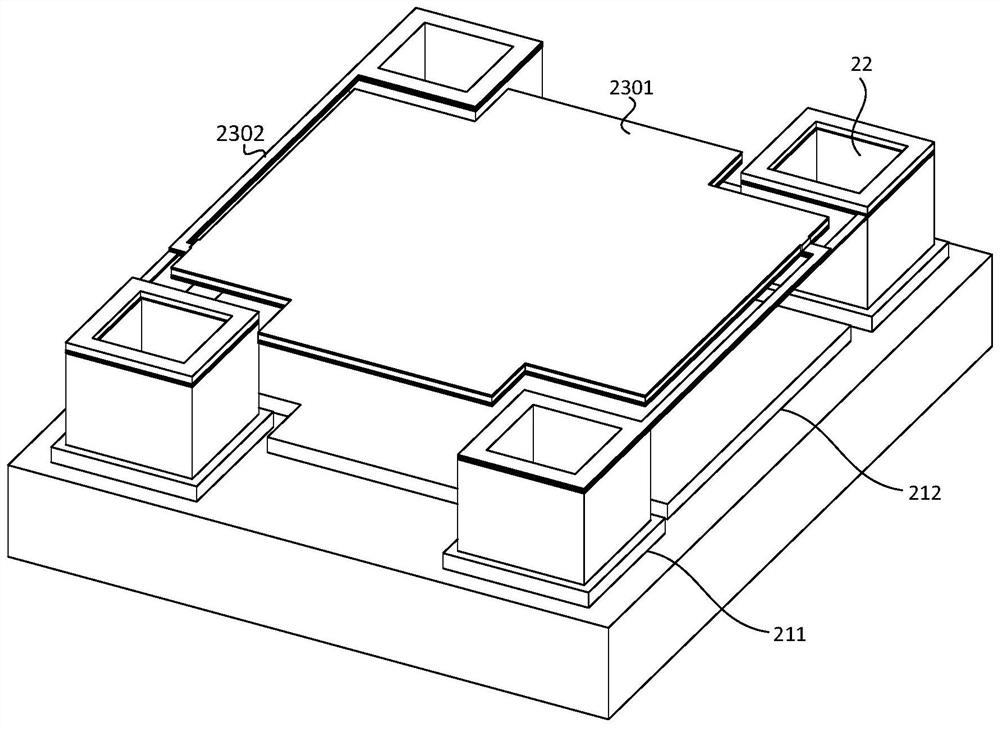

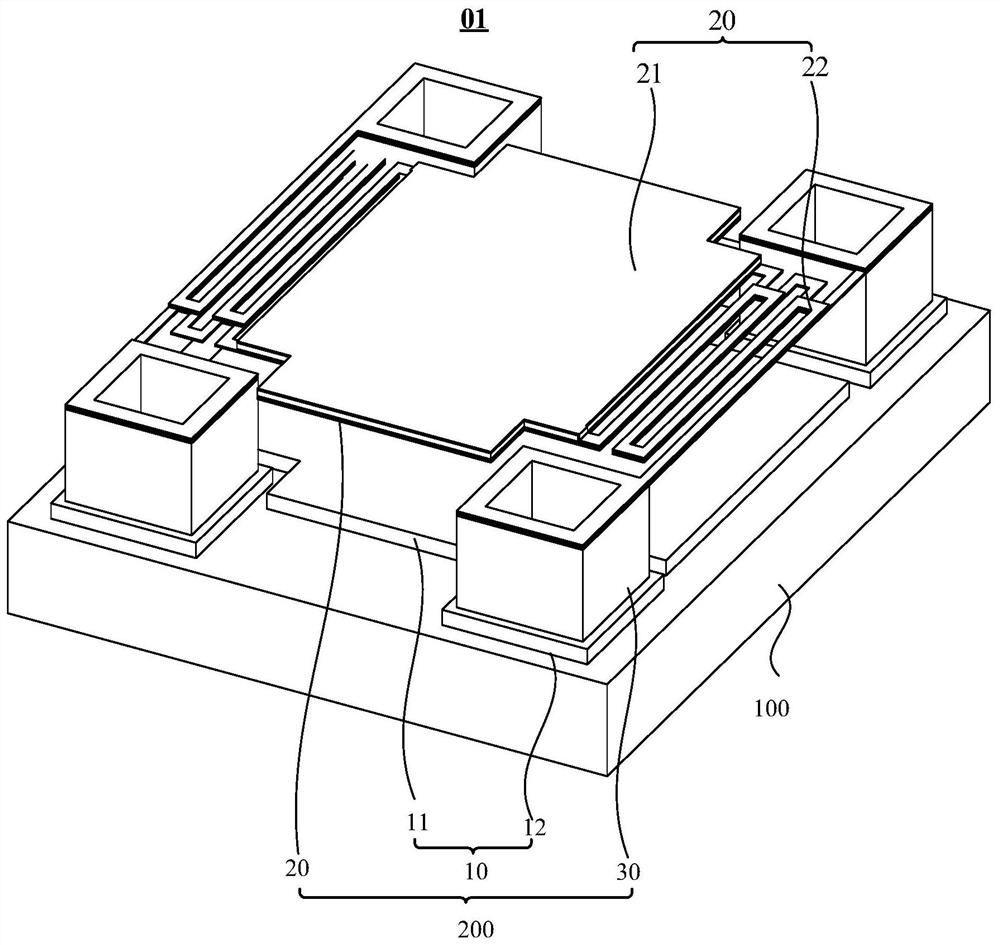

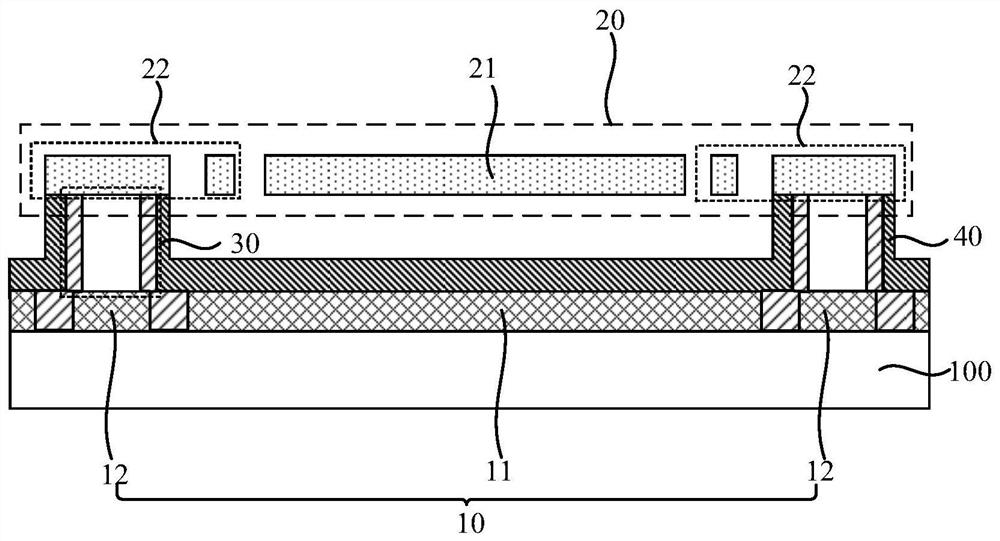

Infrared focal plane detector

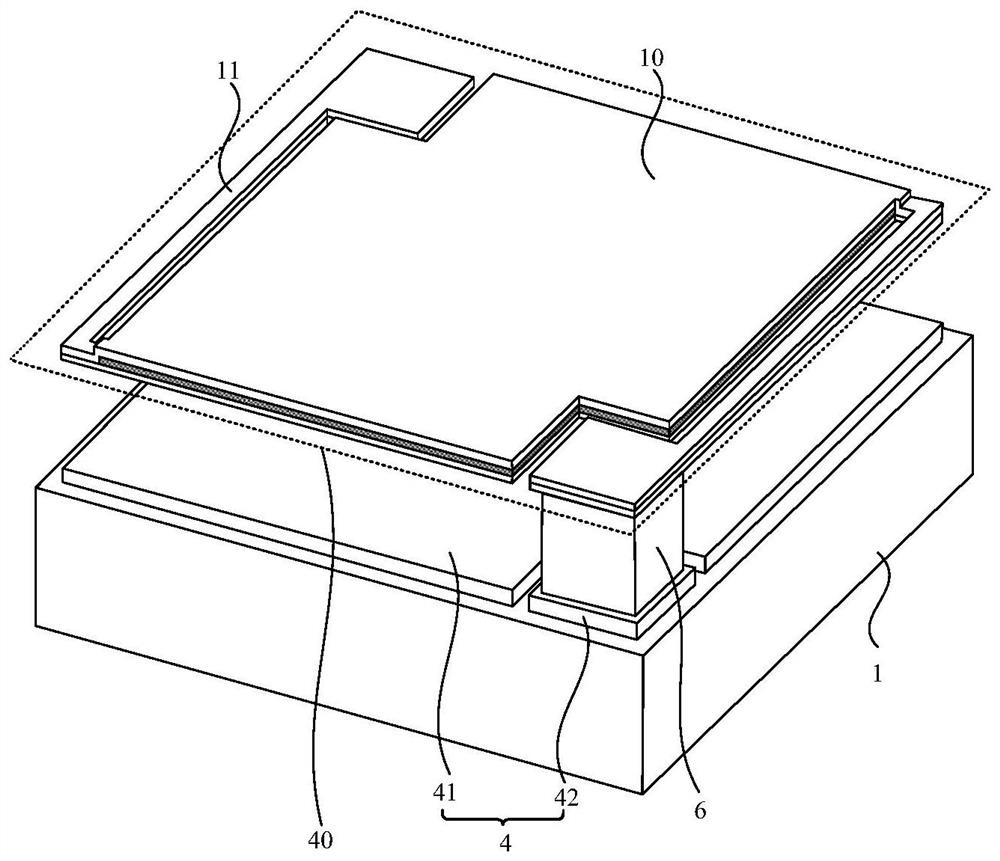

ActiveCN113447148AIncrease duty cycleLow thermal conductivityFinal product manufacturePyrometry using electric radation detectorsFocal plane detectorOptical polarization

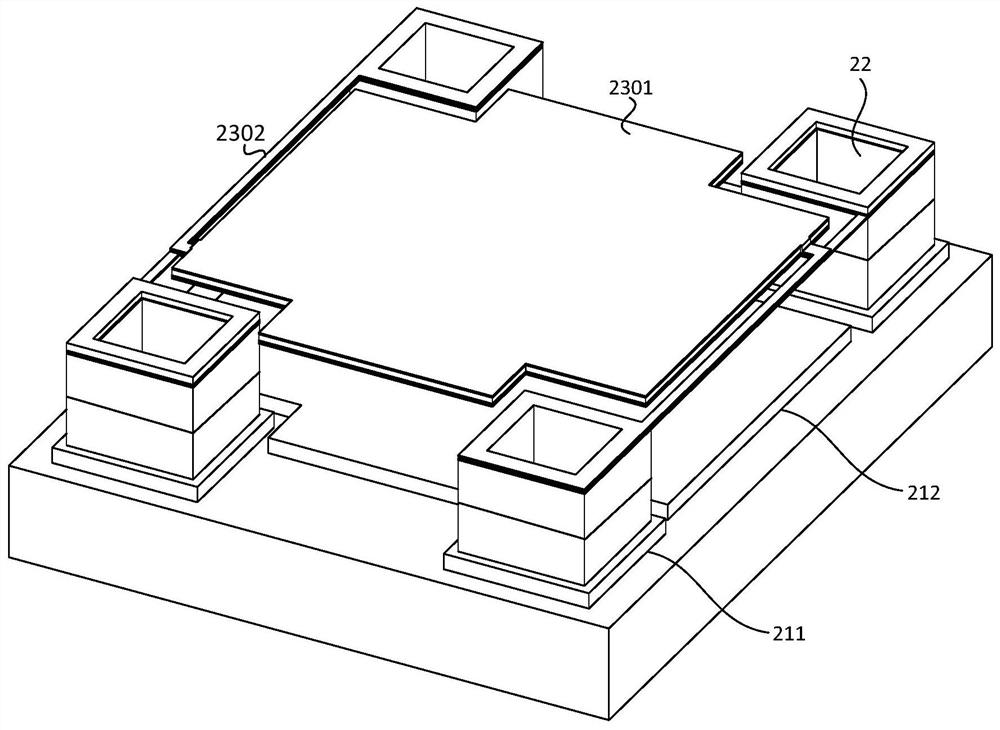

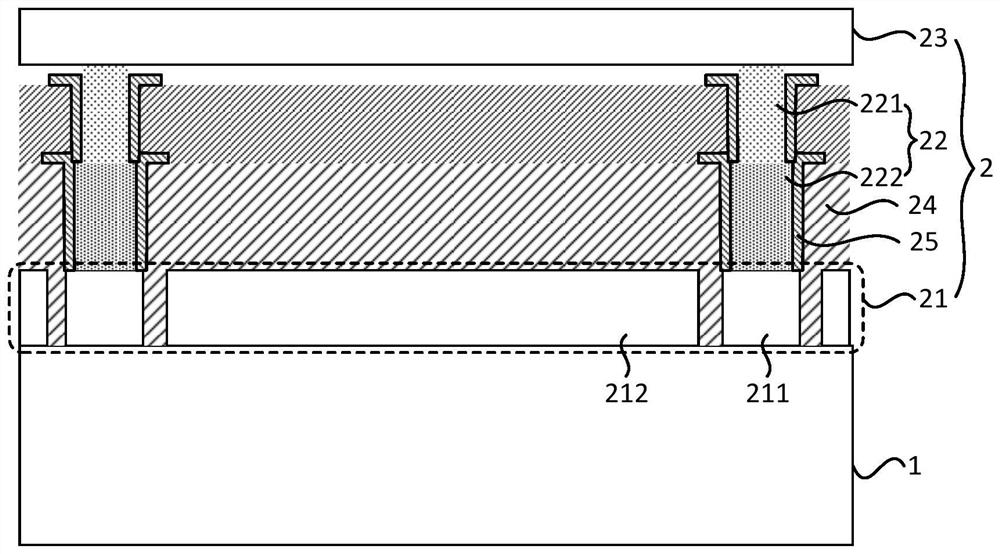

The invention relates to an infrared focal plane detector, a CMOS measurement circuit system and a CMOS infrared sensing structure in the infrared focal plane detector are both prepared by using a CMOS process, in the infrared focal plane detector, a first columnar structure is located between a reflecting layer and a beam structure, a second columnar structure is located between an absorption plate and the beam structure, the first columnar structure and the second columnar structure are solid columnar structures, and the infrared focal plane detector further comprises a metamaterial structure and / or a polarization structure. Through the technical scheme of the invention, the problems of low performance, low pixel scale, low yield and poor consistency of a traditional MEMS process infrared focal plane detector are solved, the structural stability of the infrared focal plane detector is improved, the area of the absorption plate is increased, the infrared detection sensitivity of the infrared focal plane detector is improved, the absorption rate of the infrared focal plane detector to incident infrared electromagnetic waves is improved, the performance of the infrared focal plane detector is optimized, and the difficulty of optical design of the infrared focal plane detector is reduced.

Owner:BEIJING NORTH GAOYE TECH CO LTD

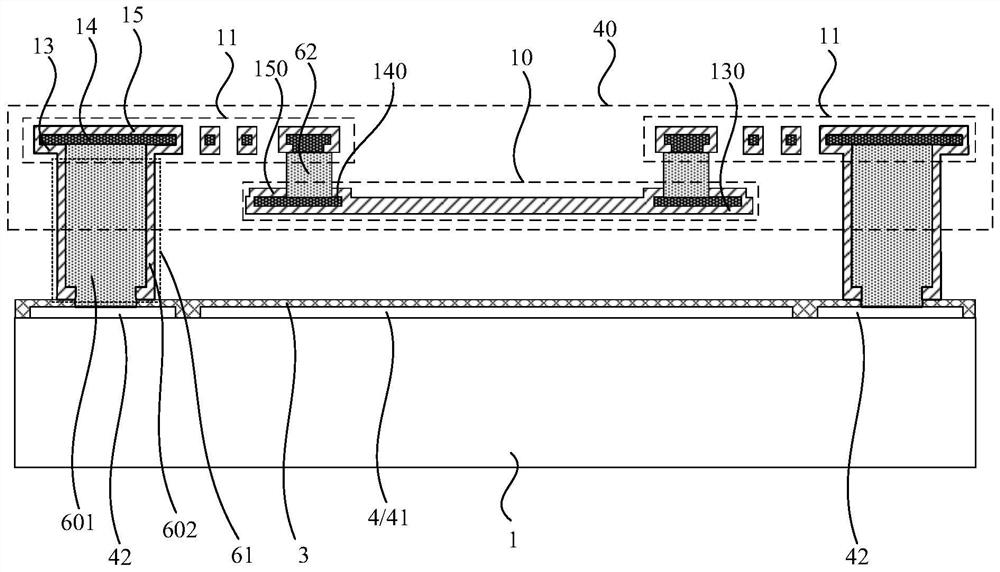

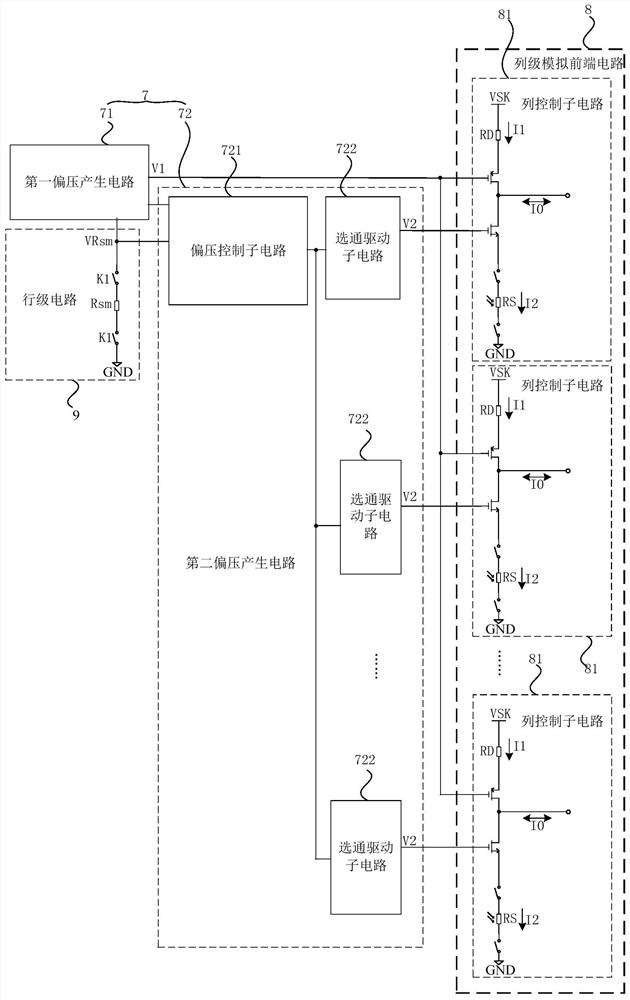

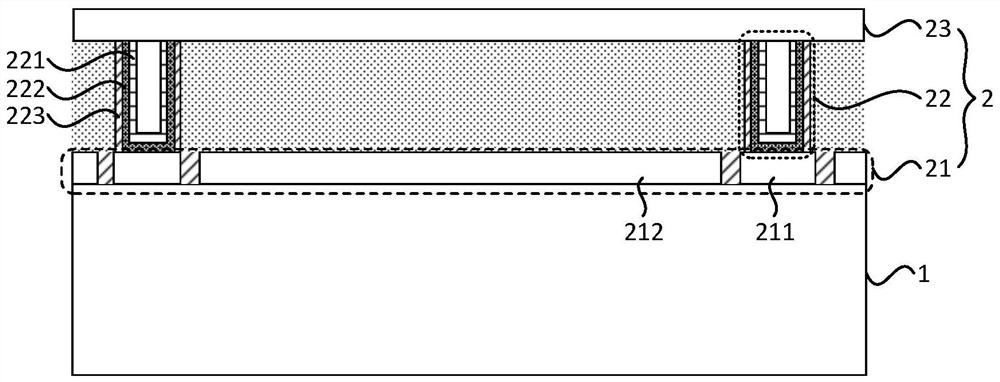

CMOS infrared microbridge detector

ActiveCN113447140AIncrease duty cycleSmall heat capacityPyrometry using electric radation detectorsEngineeringReflective layer

The present invention relates to a CMOS infrared microbridge detector. A CMOS measurement circuit system and a CMOS infrared sensing structure in the infrared micro-bridge detector are both prepared by using a CMOS process, in the infrared micro-bridge detector, a first columnar structure is located between a reflecting layer and a beam structure, a second columnar structure is located between an absorption plate and the beam structure, the first columnar structure and the second columnar structure are hollow columnar structures, the absorption plate and the beam structure comprise electrode layers and at least two dielectric layers, and the first columnar structure and the second columnar structure at least comprise electrode layers. Through the technical scheme of the invention, the problems of low performance, low pixel scale, low yield and poor consistency of a traditional MEMS process infrared focal plane detector are solved, the thermal conductance of the first columnar structure and the second columnar structure is reduced, the area of the absorption plate is increased, and the infrared detection sensitivity of the infrared micro-bridge detector is improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

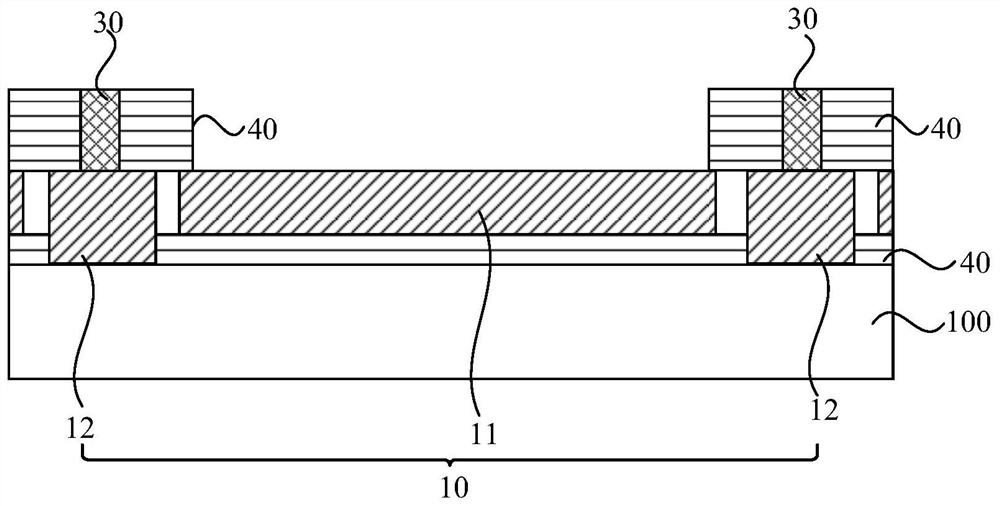

Infrared detector pixel and infrared detector based on CMOS process

PendingCN113720482AIncrease duty cycleLow thermal conductivityPyrometry using electric radation detectorsPhysical chemistryMetallic materials

The invention relates to an infrared detector pixel and an infrared detector based on a CMOS process, the pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure located on the CMOS measurement circuit system, and the CMOS measurement circuit system and the CMOS infrared sensing structure are prepared by adopting the CMOS process; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a plurality of columnar structures which are located on the CMOS measurement circuit system, the columnar structures are located between the reflecting layer and the infrared conversion structure, the reflecting layer comprises a reflecting plate and a supporting base, and the infrared conversion structure is electrically connected with the CMOS measurement circuit system through the columnar structures and the supporting base; the columnar structures adopt a non-metal solid column, the side wall of the non-metal solid column is made of a metal material, and a space surrounded by the side wall is filled with a non-metal material. According to the technical scheme, the problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved; meanwhile, the columnar structures adopt the non-metal solid column so that the structural stability can be improved, and the detection performance can be improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

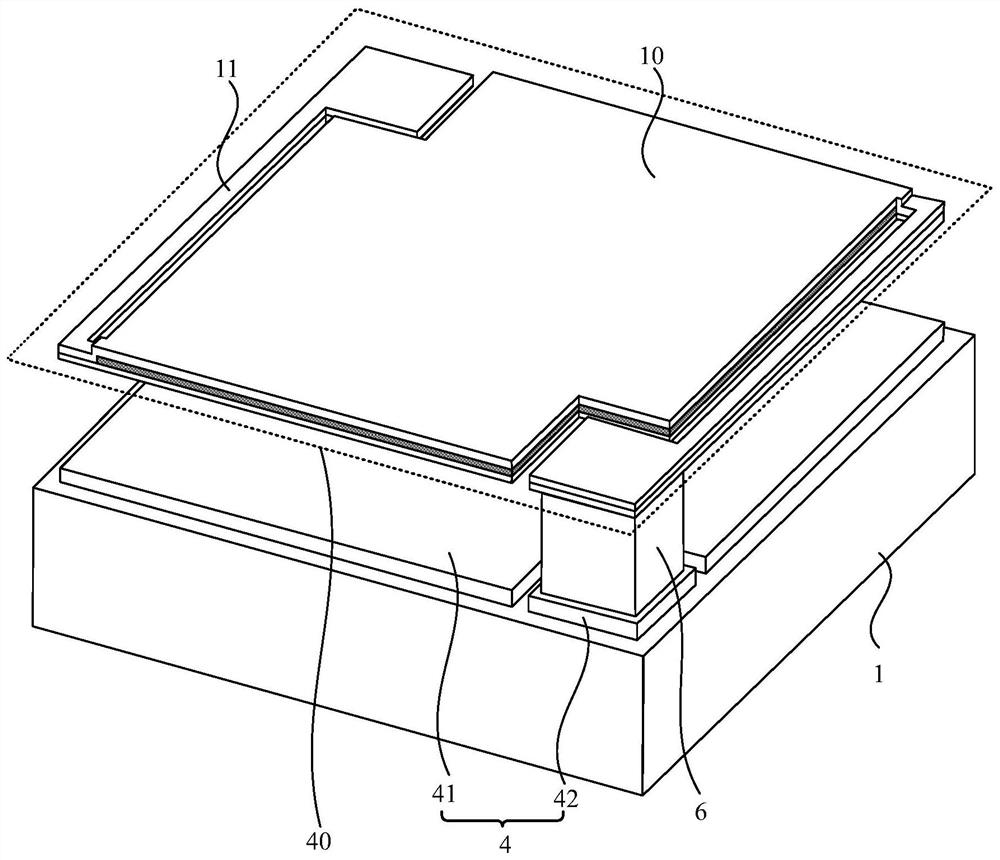

Uncooled tuning type infrared detector

ActiveCN113432724AImprove yield rateIncrease duty cycleFinal product manufacturePyrometry using electric radation detectorsIr absorptionMaterials science

The invention relates to an uncooled tuning type infrared detector, a CMOS measuring circuit system and a CMOS infrared sensing structure in the infrared detector are both prepared by using a CMOS process, the CMOS infrared sensing structure is directly prepared on the CMOS measuring circuit system, and at least one patterned metal interconnection layer is arranged between a reflecting layer and a suspended micro-bridge structure. The patterned metal interconnection layer and the reflecting layer are electrically insulated, and the patterned metal interconnection layer is used for adjusting a resonance mode of the infrared detector. According to the detector, problems of low performance, low pixel scale, low yield, poor consistency and the like of a traditional MEMS process infrared detector are solved, the infrared absorption rate of the infrared detector is effectively improved, the infrared absorption spectrum of the infrared detector is widened, and the infrared absorption spectrum of the infrared detector is increased.

Owner:BEIJING NORTH GAOYE TECH CO LTD

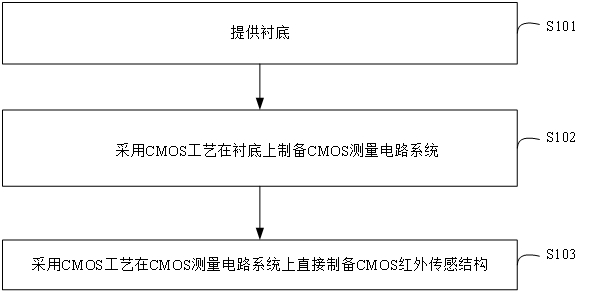

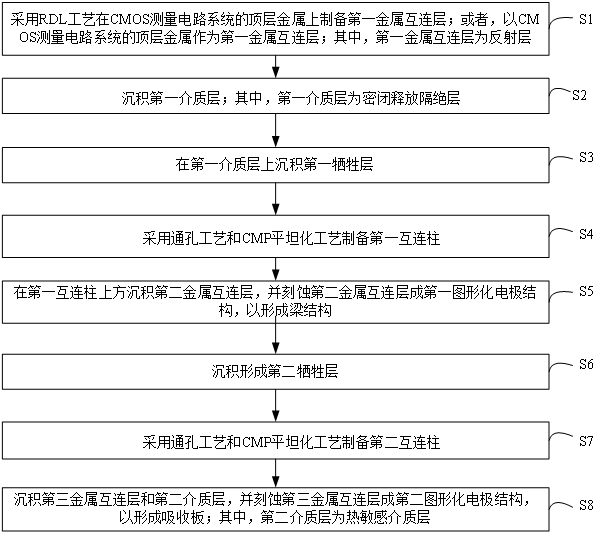

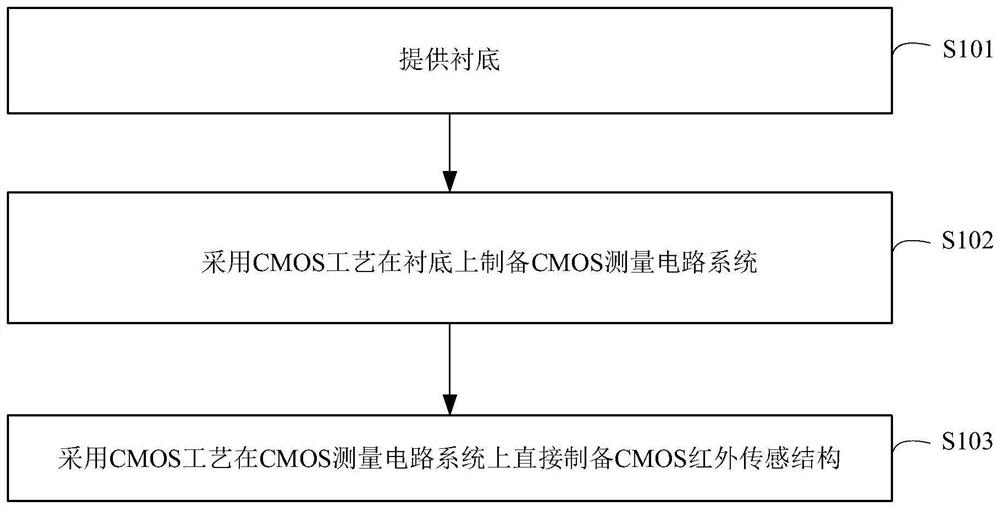

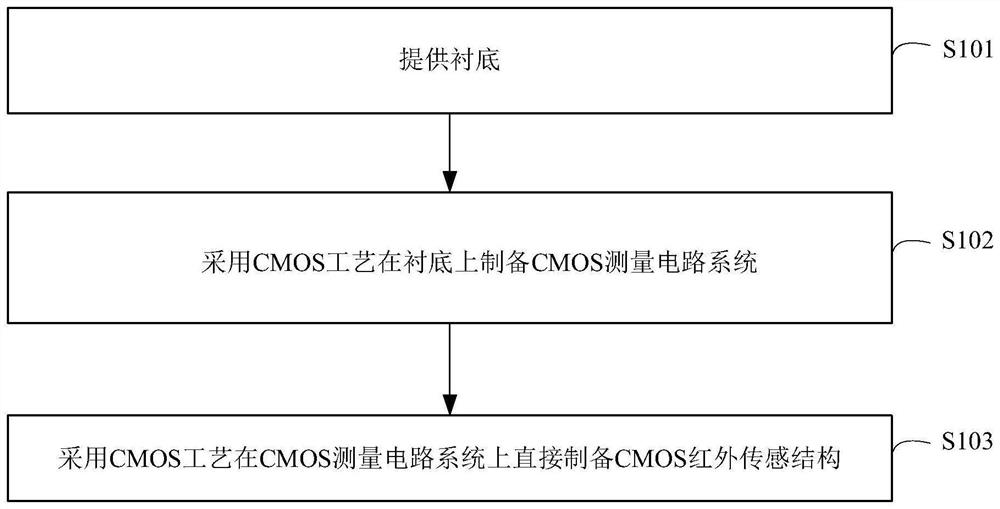

Preparation method of infrared micro-bridge detector with multilayer structure and infrared micro-bridge detector

PendingCN113639879AEasy to adjustFacilitate the realization of adjustabilityDecorative surface effectsSolid-state devicesInfraredMetal interconnect

The invention relates to a preparation method of an infrared micro-bridge detector with a multilayer structure and the infrared micro-bridge detector. The preparation method comprises the following steps: preparing a CMOS (Complementary Metal Oxide Semiconductor) measurement circuit system and a CMOS infrared sensing structure by adopting a CMOS process; the step of preparing the CMOS infrared sensing structure comprises the substeps of preparing a first metal interconnection layer on top-layer metal of a CMOS measurement circuit system by adopting an RDL process or taking the top-layer metal of the CMOS measurement circuit system as the first metal interconnection layer; preparing a first interconnection column by adopting a through hole process and a CMP planarization process; depositing a second metal interconnection layer above the first interconnection column to form a beam structure; preparing a second interconnection column by adopting a through hole process and a CMP planarization process; and depositing a third metal interconnection layer and a second dielectric layer to form the absorption plate. Through the technical scheme of the invention, the problems of low performance, low pixel scale, low yield and poor consistency of a traditional MEMS process infrared micro-bridge detector are solved, and the performance of the infrared micro-bridge detector is optimized.

Owner:BEIJING NORTH GAOYE TECH CO LTD

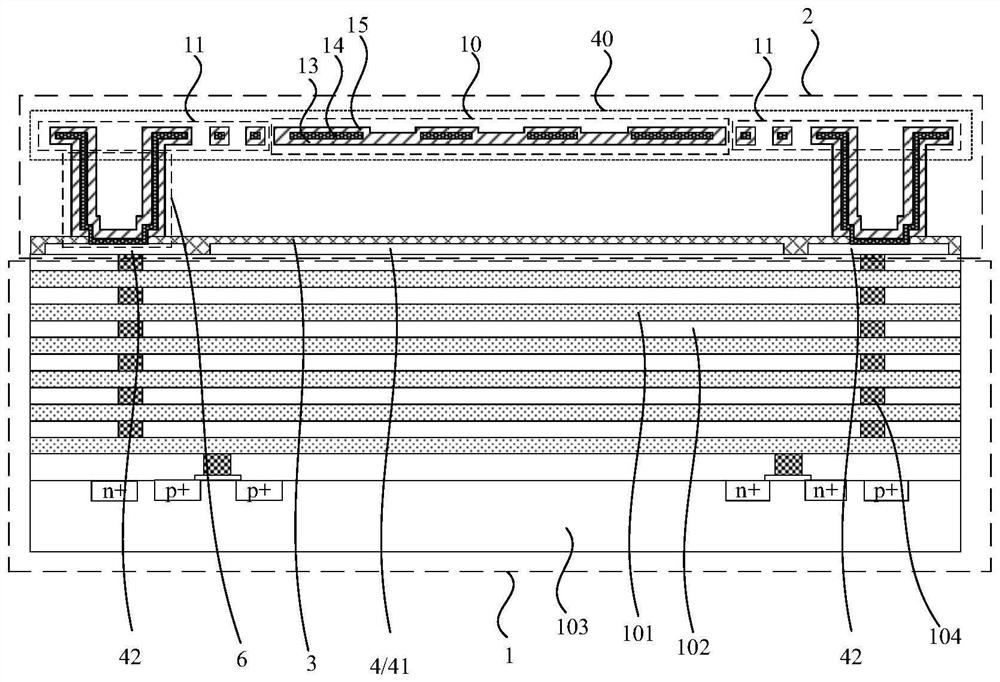

Image sensor and formation method thereof

InactiveCN109285853AQuality improvementHigh process control precisionSolid-state devicesRadiation controlled devicesInterconnectionPhotodiode

The invention provides a formation method of an image sensor. The wiring of photodiodes is connected with a diode structure, and the diode structure is controlled through an external circuit so as totimely export photon-generated carriers in the photodiodes, thereby solving a problem of image tailing. The formation method of the image sensor comprises the steps of providing three or more vertically stacked photodiodes; forming a diode structure coupled to one of the photodiodes, wherein the diode structure includes first doping regions which are arranged adjacent to each other in a vertical direction and second doping regions with the doping type being opposite to that of the first doping regions, and the photodiodes are coupled to the first doping regions; and forming a metal interconnection structure coupled to the second doping regions.

Owner:HUAIAN IMAGING DEVICE MFGR CORP

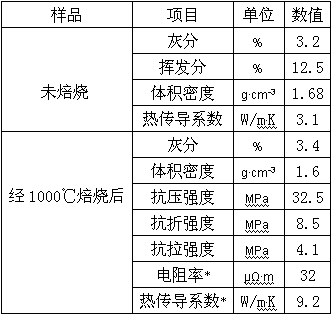

Industrial conductive material and preparation method thereof

ActiveCN105513664ASimple preparation processHigh process control precisionConductive materialCable/conductor manufactureConductive materialsHigh resistivity

The invention discloses an industrial conductive material and a preparation method thereof. The industrial conductive material is prepared by the following main materials according to weight ratio: 4.5-6 parts of electric calcined anthracite, 2-4 parts of calcined petroleum coke, 1.2-1.5 parts of resin modified bitumen, 0.03-0.06 parts of attapulgite, 0.03-0.12 parts of thorium dioxide, and 1.8-2.0 parts of intermediate-temperature coal bitumen powder. The industrial conductive material according to the invention has advantages of high industrial control precision, high strength, high resistivity, high heat conductivity, high sintering performance, high thermal shock resistance, high oxidation resistance, simple manufacture process and relatively low production cost.

Owner:徐州佳利泰新型材料科技有限公司

Infrared detector mirror image pixel and infrared detector based on CMOS process

ActiveCN113720464AImprove accuracyAccurate signal detectionFinal product manufacturePyrometry using electric radation detectorsEngineeringMirror image

The invention relates to an infrared detector mirror image pixel and an infrared detector based on a CMOS process, the mirror image pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure, the CMOS measurement circuit system and the CMOS infrared sensing structure are both prepared by using the CMOS process, and the CMOS infrared sensing structure is directly prepared on the CMOS measurement circuit system; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a plurality of columnar structures, the reflecting layer, the infrared conversion structure and the columnar structures are located on the CMOS measurement circuit system, the columnar structures are located between the reflecting layer and the infrared conversion structure, the reflecting layer comprises a supporting base, and the infrared conversion structure is electrically connected with the CMOS measurement circuit system through the columnar structures and the supporting base; and the reflecting plate arranged on the same layer as the supporting base is etched. According to the technical scheme, the problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

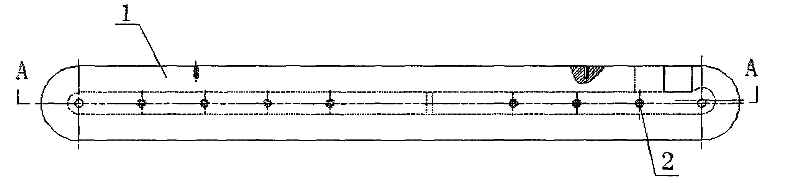

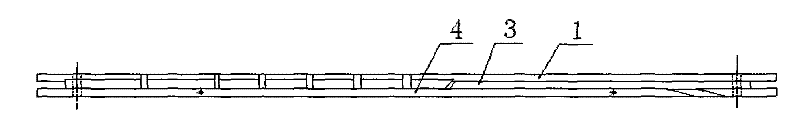

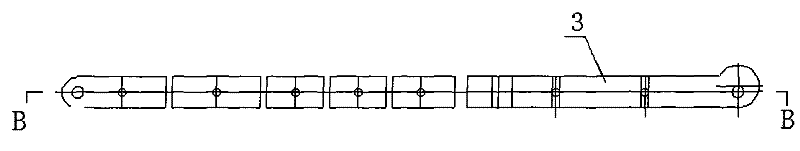

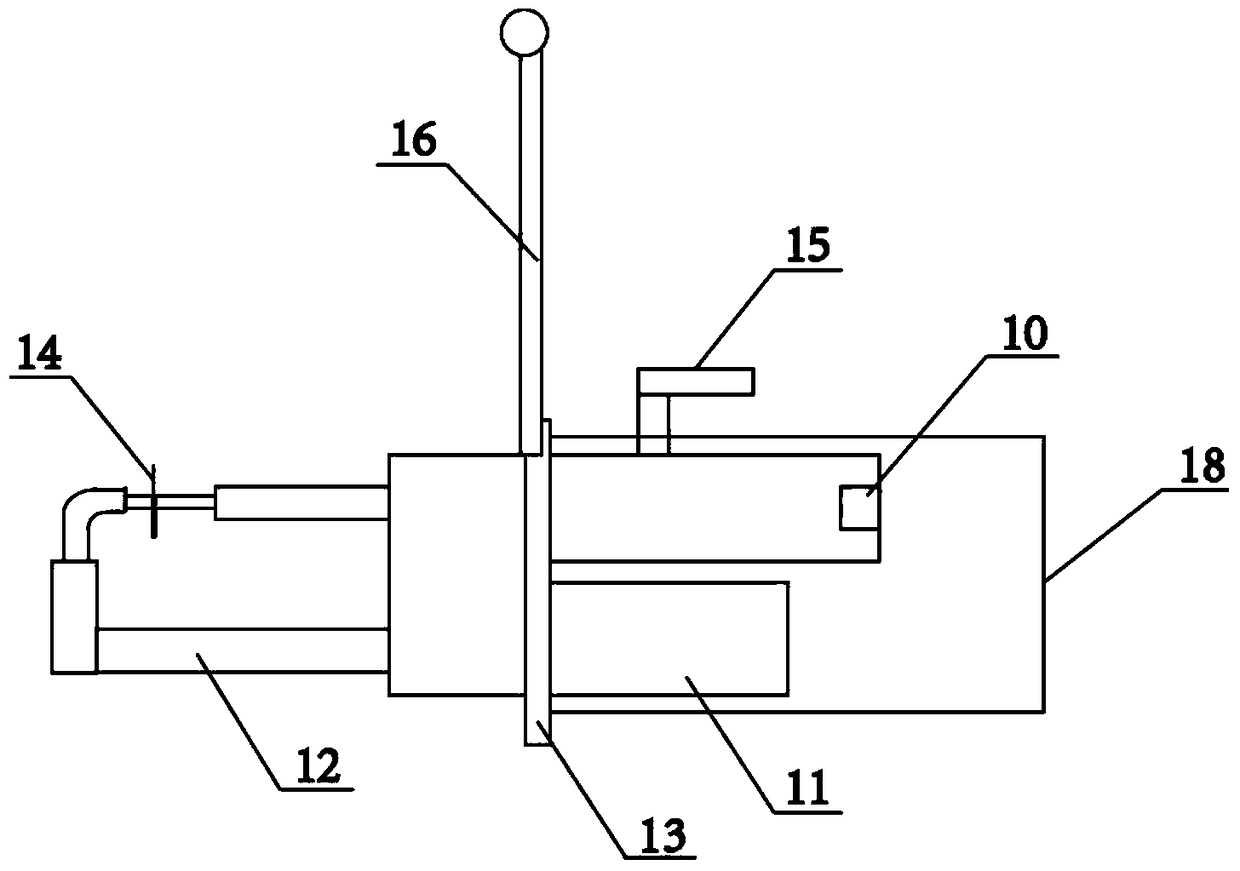

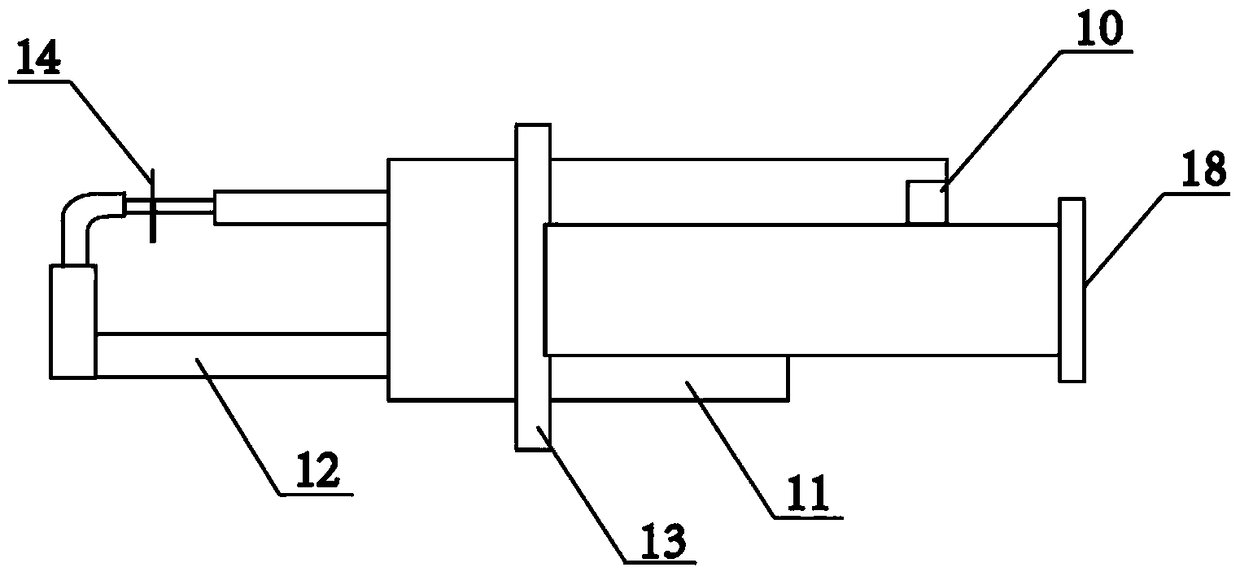

Method and device for controlling winding length of motor stator coil type coil

InactiveCN101651388BEasy windingTightly woundManufacturing dynamo-electric machinesWinding machinePull force

The invention relates to a method and a device for controlling the winding length of a motor stator coil type coil, belonging to the technical field of motors. The method for controlling the winding length of a motor stator coil type coil comprises the following steps: firstly, sequentially hoisting copper disc leads on a lead bracket; fixedly collecting the copper leads together in parallel by acollector and adjusting the tension of the leads; fixing a winding die on a winding machine, retaining 1-3 mm of copper lead rebound at the end parts of lead noses by the winding die and controlling the speed of the winding machine to wind the coil. The winding die fixed on the winding machine of the device for controlling the winding length of the motor stator coil type coil has an adjustable structure, and a die core is arranged between an inner blocking plate and an outer blocking plate; an inner die core is designed into two sections; the inner die core at the lead end is fixed on the outer blocking plate, and the inner die core subsection at the other end and the outer blocking plate are made into a structure with a guide rail. The invention has the advantages of simple and convenient process, high control precision and production efficiency, good coil winding quality, simple die structure, and the like.

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

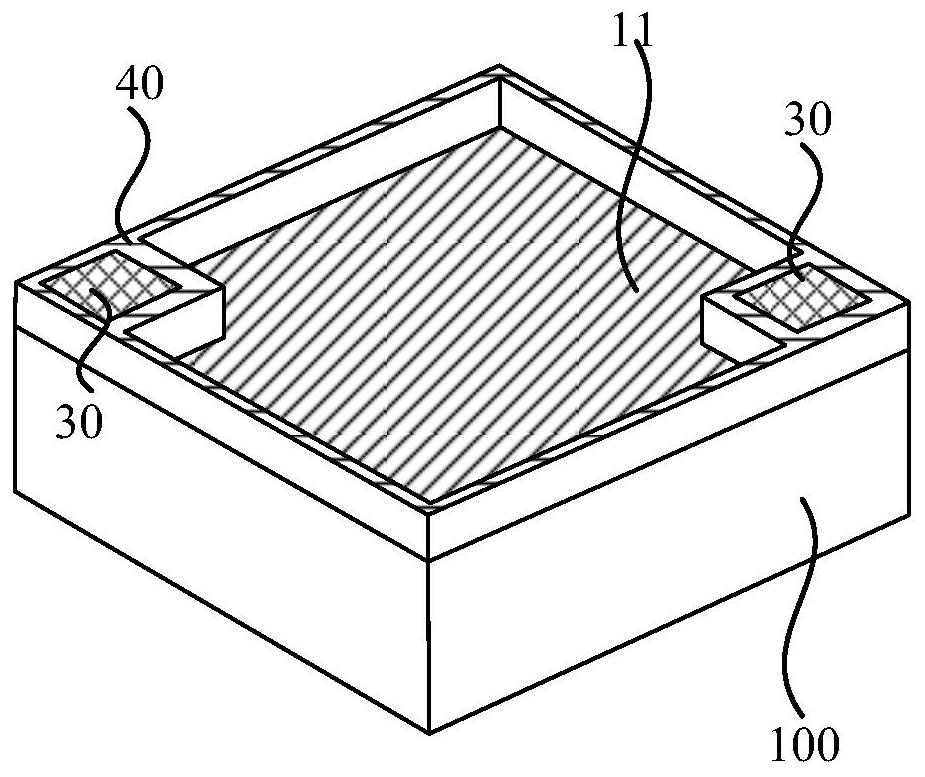

Micro-bridge structure infrared detector

ActiveCN113447150AIncrease duty cycleLow thermal conductivityPyrometry using electric radation detectorsMetal interconnectEngineering

The invention relates to a micro-bridge structure infrared detector, a CMOS measurement circuit system and a CMOS infrared sensing structure in the micro-bridge structure infrared detector are both prepared by using a CMOS process, the CMOS manufacturing process comprises a metal interconnection process, a through hole process, an IMD process and an RDL process, and a columnar structure in the micro-bridge structure infrared detector is a hollow columnar structure. The columnar structure at least comprises an electrode layer, and each of the absorption plate and the beam structure at least comprises a first dielectric layer, an electrode layer and a second dielectric layer; and the infrared detector with the micro-bridge structure further comprises a metamaterial structure and / or a polarization structure. According to the technical scheme, the problems that a traditional MEMS technology infrared detector is low in performance, low in pixel scale, low in yield, poor in consistency and the like are solved, the absorption rate of the infrared detector of the micro-bridge structure to incident infrared electromagnetic waves is improved, the performance of the infrared detector of the micro-bridge structure is optimized, and the difficulty of optical design of the infrared detector with the micro-bridge structure is reduced.

Owner:BEIJING NORTH GAOYE TECH CO LTD

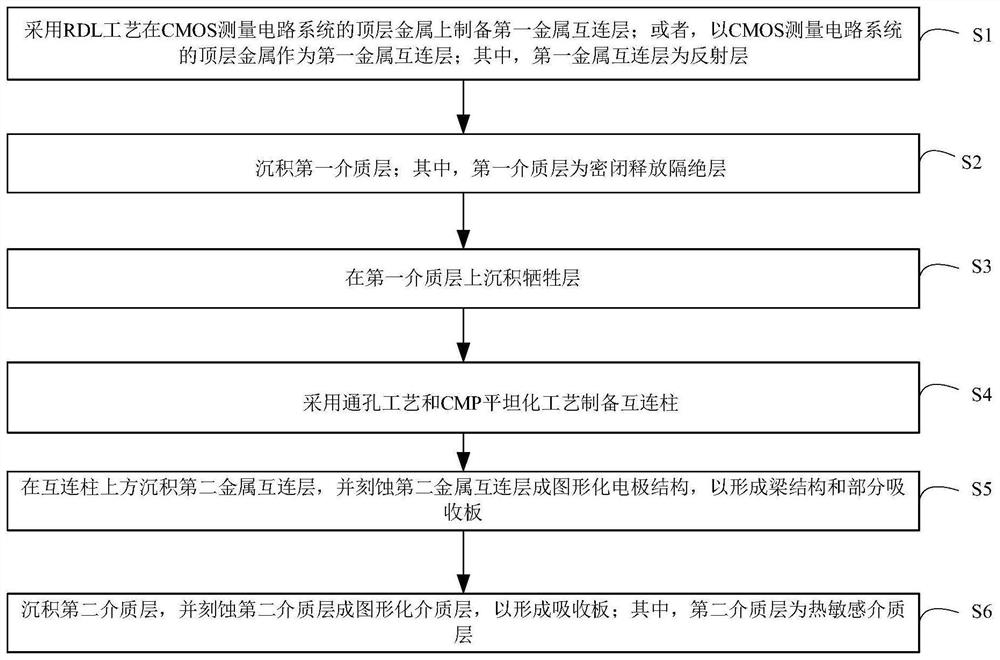

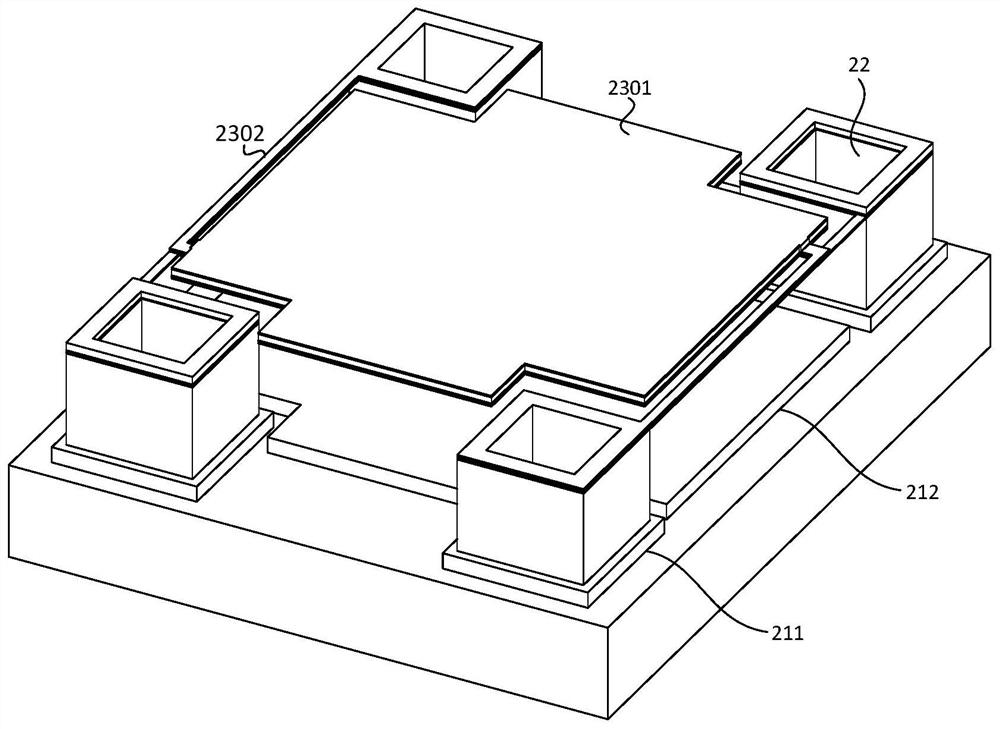

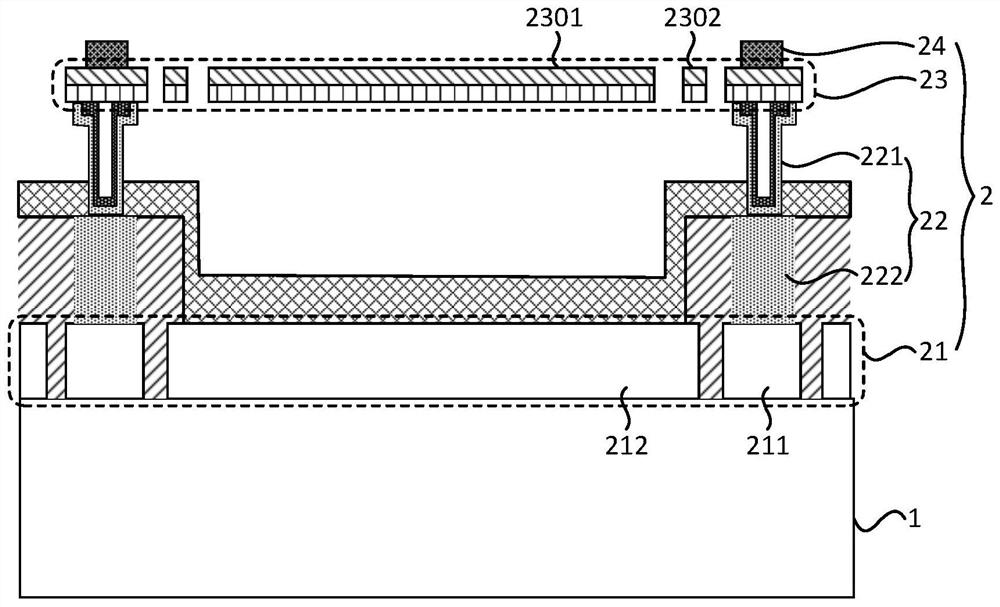

Preparation method of solid focal plane detector and solid focal plane detector

PendingCN113945285AEasy to adjustImprove yield ratePyrometry using electric radation detectorsMetal interconnectEngineering

The invention relates to a preparation method of a solid focal plane detector and the solid focal plane detector. The preparation method comprises the following steps of preparing a CMOS measurement circuit system and a CMOS infrared sensing structure by adopting a CMOS process, wherein the preparation of the CMOS infrared sensing structure comprises the substeps of preparing a first metal interconnection layer on top-layer metal of a CMOS measurement circuit system by adopting an RDL process or taking the top-layer metal of the CMOS measurement circuit system as a first metal interconnection layer; preparing an interconnection column by adopting a through hole process; and depositing a second metal interconnection layer above the interconnection column, etching the second metal interconnection layer to form a patterned electrode structure so as to form a beam structure and a part of the absorption plate, depositing a second dielectric layer, and etching the second dielectric layer to form a patterned dielectric layer so as to form the absorption plate, wherein the second dielectric layer is a heat-sensitive dielectric layer. Through the technical scheme of the invention, the problems of low performance, low pixel scale, low yield and poor consistency of the solid focal plane detector of a traditional MEMS process are solved, and the performance of the solid focal plane detector is optimized.

Owner:BEIJING NORTH GAOYE TECH CO LTD

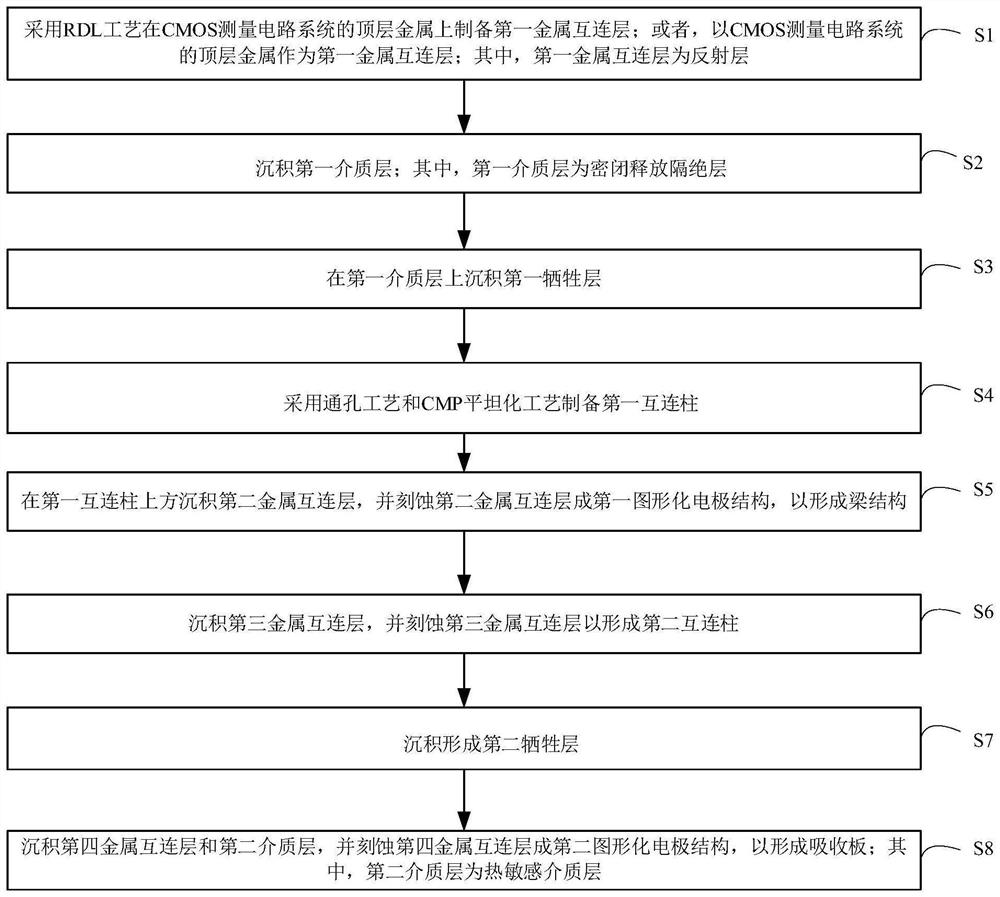

Preparation method of CMOS infrared detector with solid column and infrared detector

ActiveCN113945286AEasy to adjustBroad application marketPyrometry using electric radation detectorsMetal interconnectEngineering

The invention relates to a preparation method of a CMOS infrared detector with a solid column and the infrared detector. The preparation method comprises the following steps of preparing a CMOS measurement circuit system and a CMOS infrared sensing structure by adopting a CMOS process, wherein the preparation of the CMOS infrared sensing structure comprises the substeps of preparing a first metal interconnection layer on top-layer metal of a CMOS measurement circuit system by adopting an RDL process or taking the top-layer metal of the CMOS measurement circuit system as the first metal interconnection layer; preparing a first interconnection column by adopting a through hole process and a CMP planarization process; depositing a second metal interconnection layer above the first interconnection column to form a beam structure; depositing a third metal interconnection layer to form a second interconnection column; and depositing a fourth metal interconnection layer and a second dielectric layer to form the absorption plate. Through the technical scheme of the invention, the problems of low performance, low pixel scale, low yield and poor consistency of a traditional MEMS process infrared detector are solved, and the performance of the infrared detector is optimized.

Owner:BEIJING NORTH GAOYE TECH CO LTD

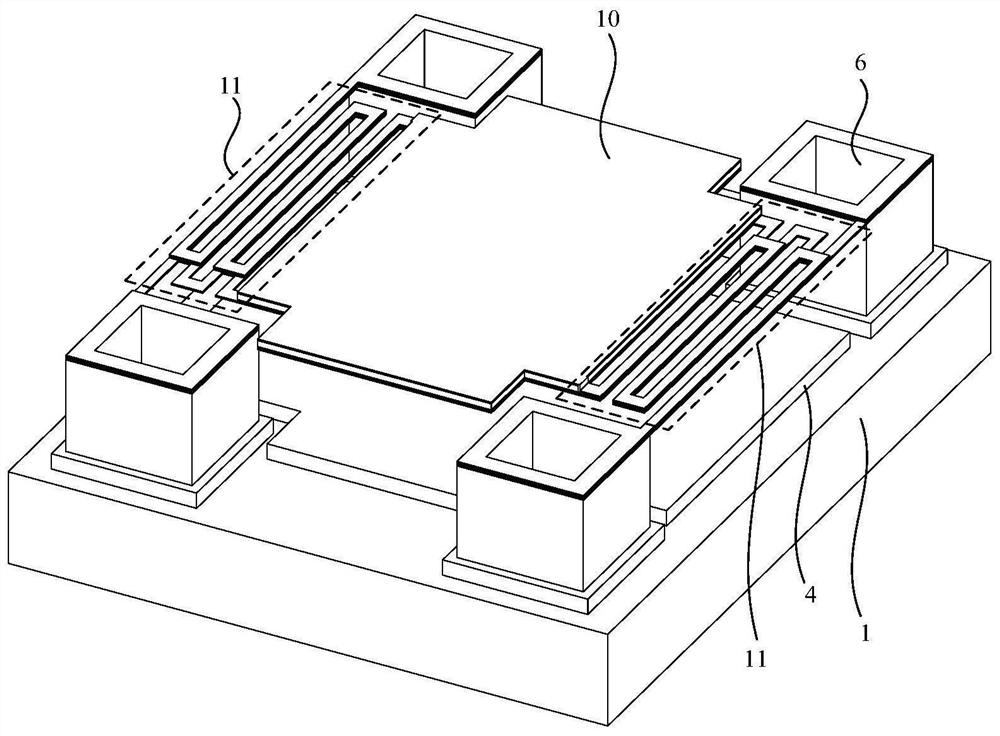

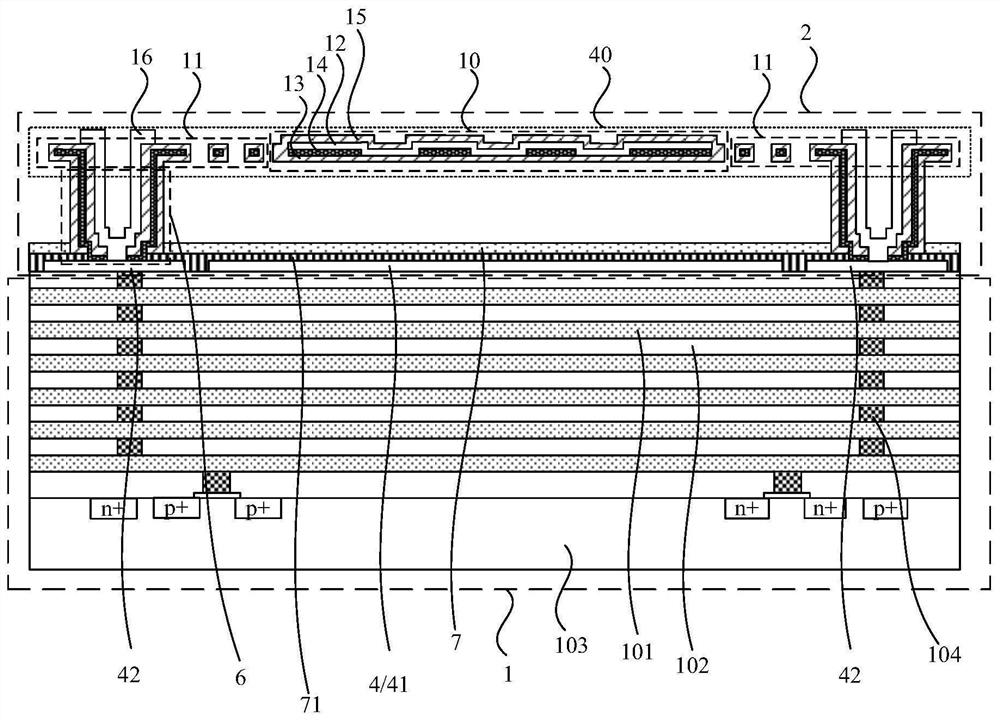

Infrared detector and pixel based on CMOS process and preparation method thereof

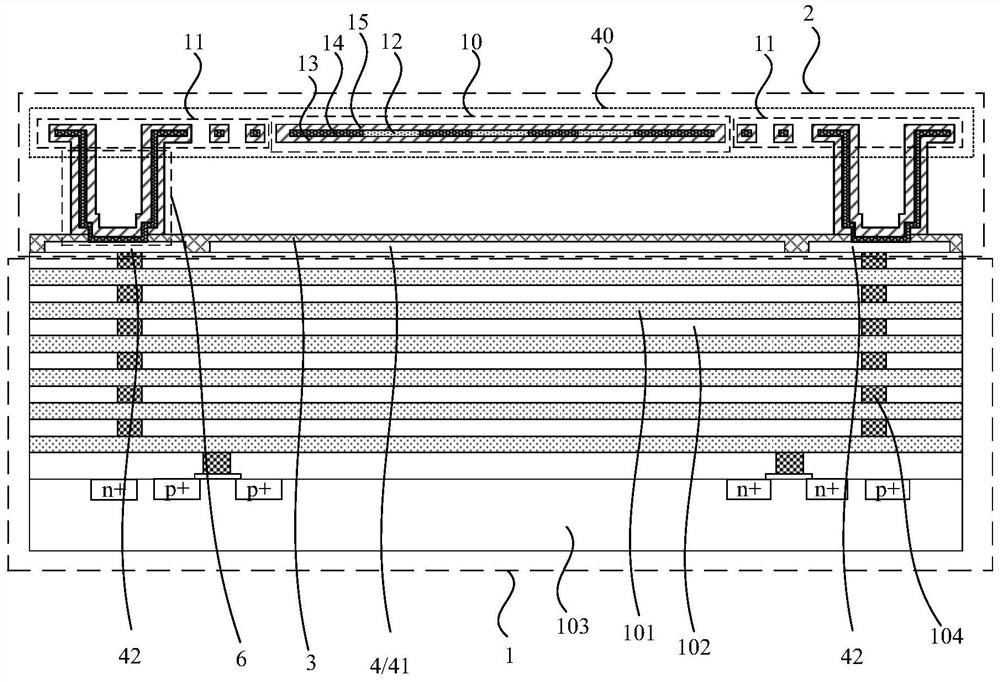

ActiveCN113720465AIncrease duty cycleLow thermal conductivityFinal product manufacturePyrometry using electric radation detectorsDielectricPhysical chemistry

The invention relates to an infrared detector pixel based on a CMOS process and a preparation method thereof, and the infrared detector pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure on the CMOS measurement circuit system which are prepared by adopting a full CMOS process; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a plurality of columnar structures which are located on the CMOS measurement circuit system, the columnar structures are located between the reflecting layer and the infrared conversion structure, the reflecting layer comprises a reflecting plate and a supporting base, and the infrared conversion structure is electrically connected with the CMOS measurement circuit system through the columnar structures and the supporting base; the CMOS infrared sensing structure further comprises a medium protection layer and an etching barrier layer which are located on the reflecting layer. The dielectric protection layer surrounds the side surface of the columnar structure, and the etching barrier layer at least covers the corner angle position of the dielectric protection layer. The problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved. Besides, the structural stability of the infrared detector is improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Single-layer infrared focal plane detector

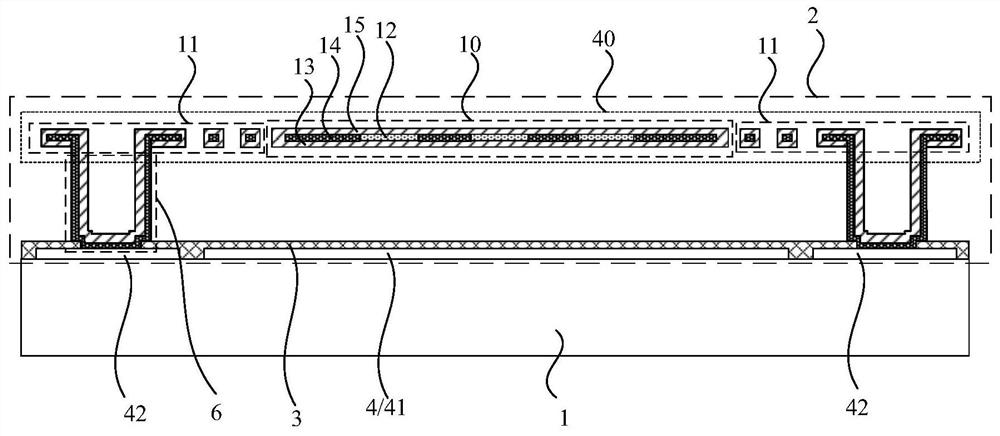

PendingCN113532661AImprove yield rateIncrease duty cyclePyrometry using electric radation detectorsMetal interconnectPhysical chemistry

The invention relates to a single-layer infrared focal plane detector, a CMOS measuring circuit system and a CMOS infrared sensing structure in the infrared focal plane detector are both prepared by using a CMOS process, and the CMOS manufacturing process comprises a metal interconnection process, a through hole process, an IMD process and an RDL process. The columnar structure in the CMOS infrared sensing structure comprises at least one layer of solid columnar structure and / or at least one layer of hollow columnar structure, the sacrificial layer is used for enabling the CMOS infrared sensing structure to form a hollow structure, the material for forming the sacrificial layer comprises at least one of silicon, germanium or germanium-silicon, the sacrificial layer is corroded by adopting an etching gas and adopting a post-CMOS process. The etching gas comprises at least one of xenon fluoride, chlorine gas, bromine gas, carbon tetrachloride and chlorofluorohydrocarbon. According to the technical scheme, the problems that a traditional MEMS technology infrared focal plane detector is low in performance, low in pixel scale, low in yield, poor in consistency and the like are solved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Infrared detector pixel and infrared detector based on CMOS process

ActiveCN113720471AIncrease duty cycleLow thermal conductivityPyrometry using electric radation detectorsMid infraredEngineering

The invention relates to an infrared detector pixel and an infrared detector based on a CMOS process, the infrared detector pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure located on the CMOS measurement circuit system, at least one closed release isolation layer is arranged on the CMOS measurement circuit system, and the at least one closed release isolation layer is located in the CMOS infrared sensing structure; the infrared conversion structure comprises an absorption plate and a plurality of beam structures, in at least part of the orthographic projection area of the absorption plate, the closed release isolation layer located in the CMOS infrared sensor structure is etched, at least one closed release isolation layer is located on the interface between the CMOS measurement circuit system and the CMOS infrared sensor structure, and the problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved, and the release difficulty of the sacrificial layer is reduced by the closed release isolation layer in the CMOS infrared sensing structure.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Infrared detector pixel based on complementary metal oxide semiconductor (CMOS) process and infrared detector

PendingCN114112056AReduce shipping costsReduce transportationPyrometry using electric radation detectorsIr detectorOxide semiconductor

The invention relates to an infrared detector pixel based on a CMOS (Complementary Metal Oxide Semiconductor) process and an infrared detector, and the pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure on the CMOS measurement circuit system, and is prepared by adopting a full CMOS process; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a plurality of columnar structures which are located on the CMOS measuring circuit system, the columnar structures are located between the reflecting layer and the infrared conversion structure, the reflecting layer comprises a reflecting plate and a supporting base, and the infrared conversion structure is electrically connected with the CMOS measuring circuit system through the columnar structures and the supporting base; the infrared conversion structure comprises an absorption plate and a plurality of beam structures, and the absorption plate is used for converting infrared signals into electric signals and is electrically connected with the corresponding columnar structures through the corresponding beam structures; the infrared detector pixel further comprises a reinforcing structure. And the reinforcing structure is used for enhancing the connection stability between the columnar structure and the beam structure. Therefore, the problems of low performance, low pixel scale, low yield and the like of a traditional MEMS process infrared detector are solved; and the structural stability is improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Infrared detector based on CMOS process

ActiveCN113720451AIncrease duty cycleLow thermal conductivityFinal product manufacturePhotometry electrical circuitsResonant cavityMetal interconnect

The invention relates to an infrared detector based on a CMOS process, a CMOS measurement circuit system and a CMOS infrared sensing structure in the infrared detector are both prepared by using the CMOS process, and the CMOS infrared sensing structure is directly prepared on the CMOS measurement circuit system; the CMOS manufacturing process of the CMOS infrared sensing structure comprises a metal interconnection process, a through hole process and an RDL process, the CMOS infrared sensing structure comprises at least two metal interconnection layers, at least two dielectric layers and a plurality of interconnection through holes, the dielectric layers at least comprise a sacrificial layer and a heat-sensitive dielectric layer, and the heat-sensitive dielectric layer comprises a heat-sensitive material of which the resistance temperature coefficient is greater than a set value; the CMOS infrared sensing structure comprises a resonant cavity formed by a reflecting layer and a heat-sensitive dielectric layer, a suspended micro-bridge structure for controlling heat transfer and a columnar structure with electric connection and supporting functions. According to the technical scheme, the problems that a traditional MEMS technology infrared detector is low in performance, low in pixel scale, low in yield and the like are solved, and the performance of the infrared detector is optimized.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Infrared detector pixel and infrared detector based on CMOS process

ActiveCN113720483AIncrease duty cycleLow thermal conductivityFinal product manufacturePyrometry using electric radation detectorsDielectricMaterials science

The invention relates to an infrared detector pixel and an infrared detector based on a CMOS process, and the infrared detector pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure on the CMOS measurement circuit system which are prepared through a full CMOS process; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure, a plurality of columnar structures, a dielectric protection layer and an etching barrier layer, wherein the dielectric protection layer and the etching barrier layer are located on the reflecting layer. The columnar structures comprise at least two layers of stand columns which are arranged in an overlapped mode and located between the reflecting layer and the infrared conversion structure, the reflecting layer comprises a reflecting plate and a supporting base, and the infrared conversion structure is electrically connected with the CMOS measurement circuit system through the columnar structures and the supporting base; each layer of stand columns can be at least one of solid metal columns, non-metal solid columns or hollow columns; the dielectric protection layer surrounds the side surface of the columnar structures, and the etching barrier layer at least covers the corner angle position of the dielectric protection layer. Therefore, the problems of low performance, low pixel scale, low yield and the like of a traditional MEMS process infrared detector are solved; and the detection sensitivity and the structural stability are improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

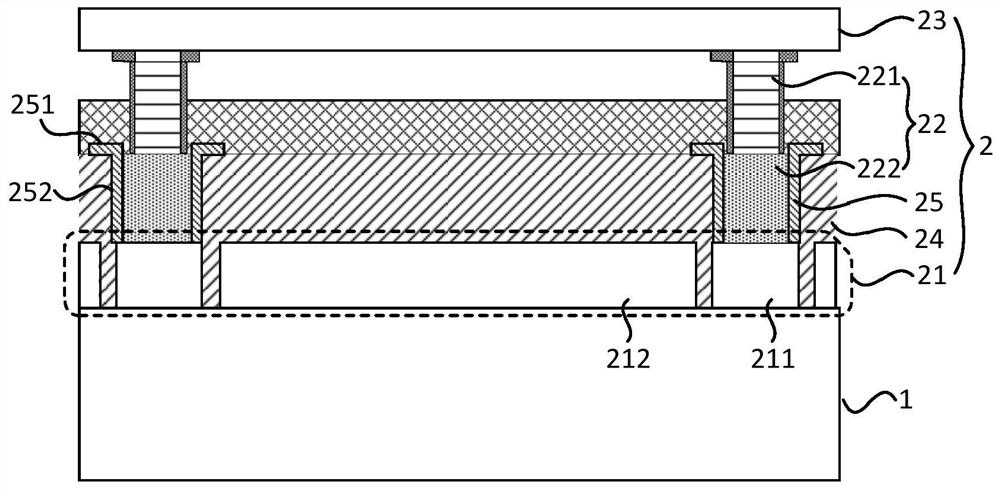

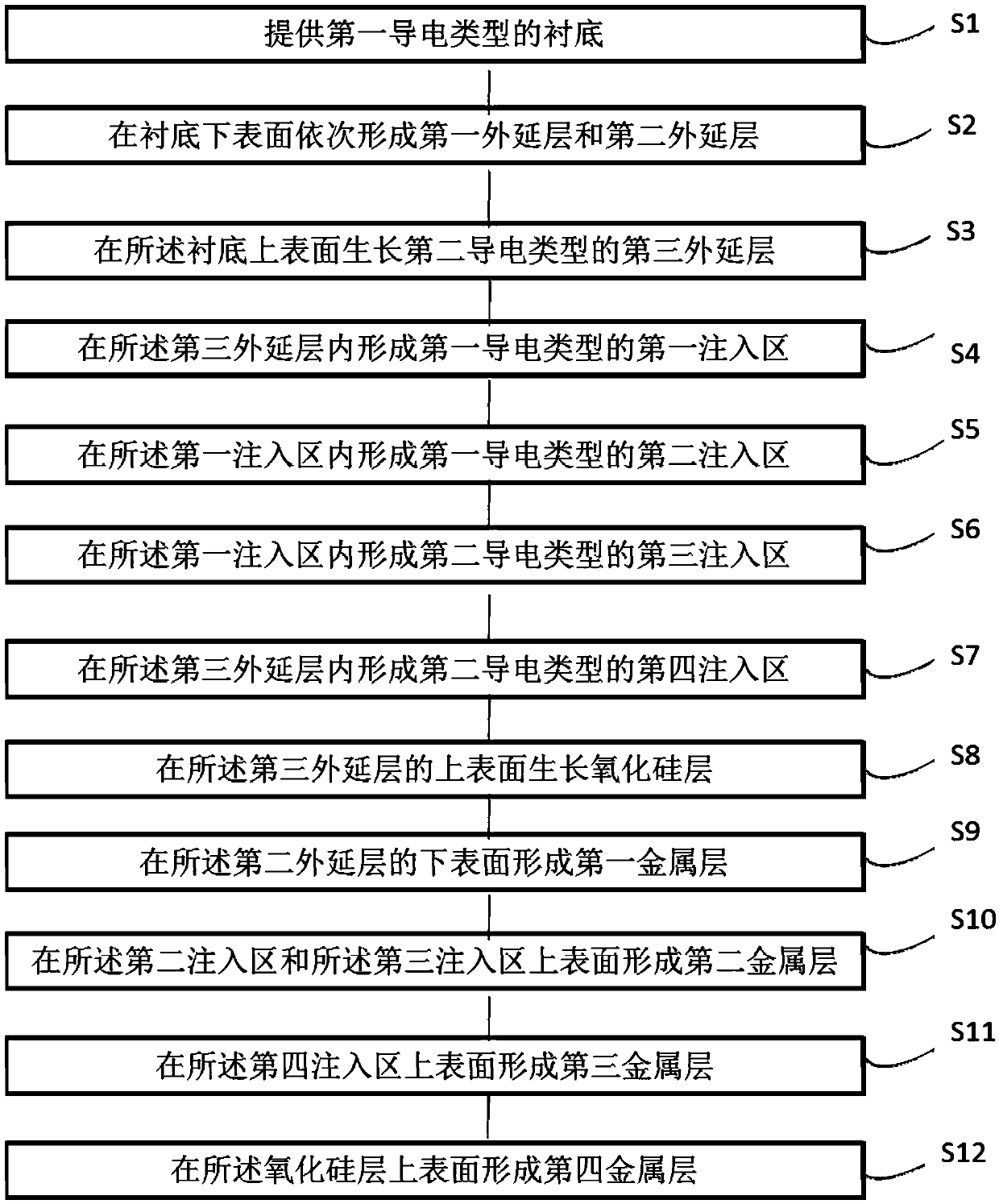

Metal oxide semiconductor turn-off thyristor and manufacturing method thereof

InactiveCN109599433AHigh process control precisionEase of mass productionThyristorSemiconductor/solid-state device manufacturingThyratronSilicon oxide

The present invention provides a metal oxide semiconductor turn-off thyristor and a manufacturing method thereof, the thyristor comprises: a substrate of a first conductivity type, a first epitaxial layer of a second conductivity type, a second epitaxial layer of the second conductivity type, and a third epitaxial layer of the second conductivity type, a first injection region of the first conductivity type formed on the third epitaxial layer, a second injection region of the first conductivity type formed in the first injection region, and a third injection region of the second conductivity type formed in the first injection region, a fourth injection region of the second conductivity type formed in the third epitaxial layer, a silicon oxide layer formed on upper surface of the third epitaxial layer, an anode, a cathode, a first gate electrode, and a second gate electrode. The thyristor has low manufacturing difficulty, high process control precision, and is suitable for mass production.

Owner:泉州臻美智能科技有限公司

Infrared detector pixel and infrared detector based on CMOS process

ActiveCN113720469AIncrease duty cycleLow thermal conductivityFinal product manufacturePyrometry using electric radation detectorsPhysical chemistryEngineering

The invention relates to an infrared detector pixel and an infrared detector based on a CMOS process, and the pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure on the CMOS measurement circuit system which are prepared by adopting a full CMOS process; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a plurality of columnar structures, and the columnar structures are located between the reflecting layer and the infrared conversion structure; the reflecting layer comprises a reflecting plate and a supporting base, and the infrared conversion structure is electrically connected with the CMOS measurement circuit system through the columnar structures and the supporting base; the infrared conversion structure comprises an absorption plate and a beam structure, and the absorption plate is electrically connected with the columnar structures through the beam structure; the columnar structures comprise at least two layers of stand columns, and each layer of stand columns can be at least one of solid metal columns, non-metal solid columns or hollow columns. The pixel further comprises a reinforcing structure which is used for enhancing the connection stability between the columnar structures and the infrared conversion structure. The problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved. The sensitivity is high and the stability is good.

Owner:BEIJING NORTH GAOYE TECH CO LTD

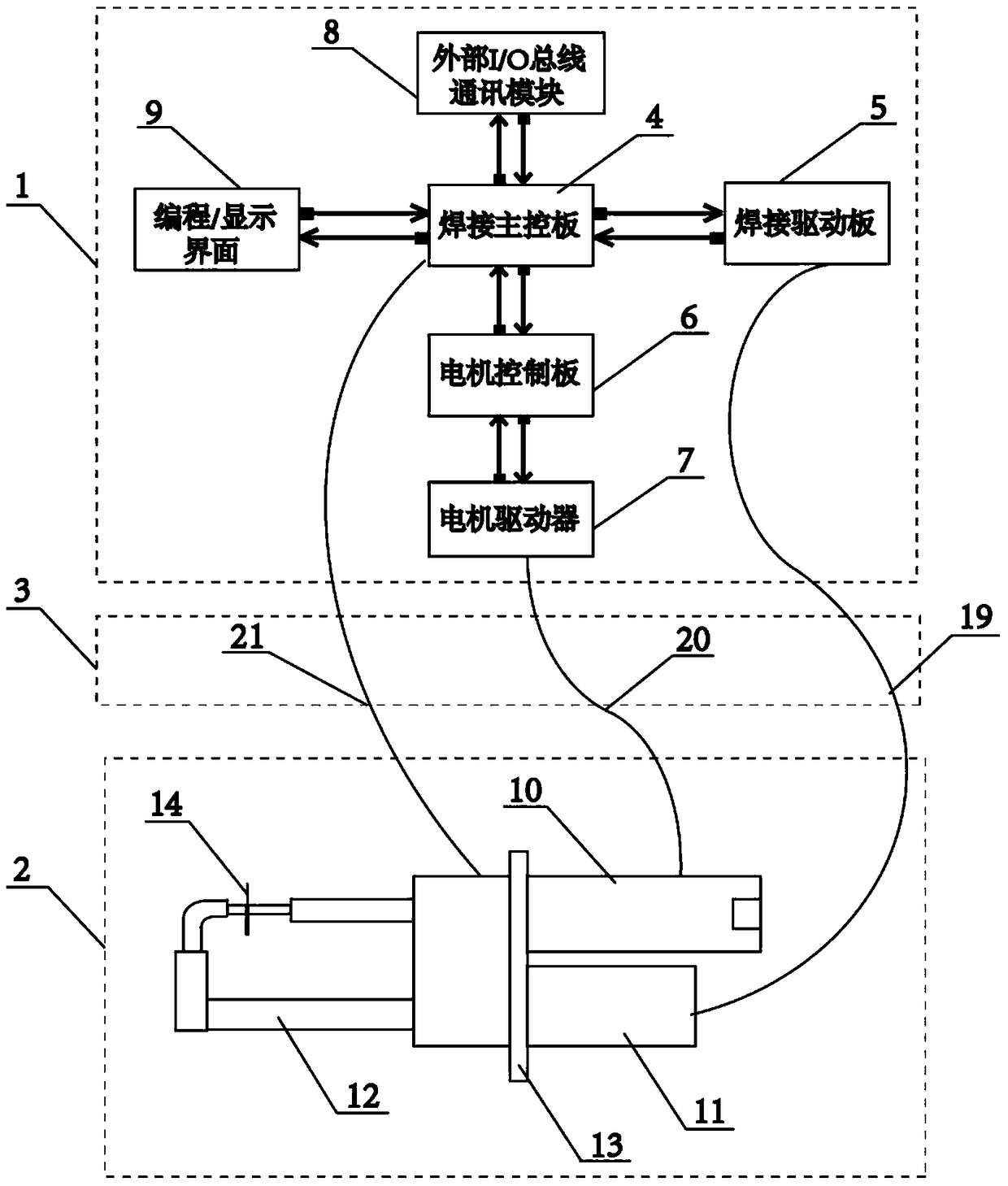

Servo pressure spot welding system

ActiveCN105522302BWelding time synchronization controlWelding current synchronous controlWelding/cutting auxillary devicesAuxillary welding devicesTransformerWelding power supply

Owner:天津七所高科技有限公司

Infrared detector mirror pixel and infrared detector based on cmos technology

ActiveCN113720481BReduce manufacturing costImprove accuracyPyrometry using electric radation detectorsEngineeringMirror image

The disclosure relates to an infrared detector mirror image element and an infrared detector based on CMOS technology. The mirror image element includes: CMOS measurement circuit system and CMOS infrared sensing structure are both prepared by CMOS technology, and directly prepared above the CMOS measurement circuit system CMOS infrared sensing structure; the infrared conversion structure is electrically connected to the CMOS measurement circuit system through the columnar structure and the supporting base; the infrared conversion structure includes an absorption plate and a beam structure located on the same layer, and the absorption plate converts the infrared signal into an electrical signal and passes through the beam structure It is electrically connected with the columnar structure; the absorption plate includes a metal structure on one side close to or away from the CMOS measurement circuit system, and at least part of the reflection plate is located in the orthographic projection of the metal structure. Through the technical proposal of the present disclosure, the problems of low performance, low pixel scale and low yield rate of infrared detectors in traditional MEMS technology are solved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Uncooled titanium oxide CMOS infrared detector

PendingCN113447145AImprove yield rateIncrease duty cyclePyrometry using electric radation detectorsMetal interconnectTitanium oxide

The invention relates to an uncooled titanium oxide CMOS infrared detector, a CMOS measuring circuit system and a CMOS infrared sensing structure in the infrared detector are both prepared by using a CMOS process, the CMOS manufacturing process comprises a metal interconnection process, a through hole process, an IMD process and an RDL process, and a columnar structure in the infrared detector is a hollow columnar structure. The absorption plate comprises a first dielectric layer, an electrode layer, a heat-sensitive dielectric layer and a second dielectric layer, the electrode layer and the heat-sensitive dielectric layer are arranged on the same layer, the electrode layer is made of titanium, and the heat-sensitive dielectric layer is made of titanium oxide; or, the electrode layer is made of highly-doped titanium oxide, and the heat-sensitive dielectric layer is made of titanium oxide. According to the technical scheme, the problems that a traditional MEMS technology infrared detector is low in performance, low in pixel scale, low in yield, poor in consistency and the like are solved, and the preparation technology of the infrared detector can be simplified.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Infrared detector pixel and infrared detector based on CMOS process

ActiveCN113720479AReduce shipping costsSimple preparation processFinal product manufacturePyrometry using electric radation detectorsIr detectorThermal emission

The invention relates to an infrared detector pixel and an infrared detector based on a CMOS process, the pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure located on the CMOS measurement circuit system, and the CMOS measurement circuit system and the CMOS infrared sensing structure are prepared by adopting the CMOS process; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a plurality of columnar structures which are located on the CMOS measurement circuit system, the columnar structures are located between the reflecting layer and the infrared conversion structure, the reflecting layer comprises a reflecting plate and a supporting base, and the infrared conversion structure is electrically connected with the CMOS measurement circuit system through the columnar structures and the supporting base; the columnar structures adopt a hollow column, and the side wall of the hollow column is formed by combining metal and a medium. According to the technical scheme, the problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved; and the columnar structures adopt the hollow column so that the heat conduction is smaller, the influence of heat radiation generated by the columnar structure on an electric signal of the infrared conversion structure is reduced, and the detection performance is favorably improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Forming method for image sensor

InactiveCN108734071AReduce processing difficultyHigh process control precisionPrint image acquisitionProtection layerComputer science

The invention discloses a forming method for an image sensor. The method comprises the following steps of providing a laminated substrate, wherein the laminated substrate comprises a supporting layerand a base layer arranged on the supporting layer; forming a pixel array on the base layer; forming a protection layer on the pixel array; and removing the supporting layer to obtain the image sensor.According to the technical scheme, the thickness of the formed image sensor can be effectively reduced, so that the thickness of a fingerprint imaging module can be reduced.

Owner:SHANGHAI OXI TECH

Infrared detector pixel and infrared detector based on CMOS process

ActiveCN113720453AIncrease duty cycleLow thermal conductivityFinal product manufacturePhotometry electrical circuitsMid infraredIsolation layer

The invention relates to an infrared detector pixel and an infrared detector based on a CMOS process. The infrared detector pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure located on the CMOS measurement circuit system. At least one airtight release isolation layer is arranged on the CMOS measurement circuit system, and the at least one airtight release isolation layer is located in the CMOS infrared sensing structure; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a plurality of columnar structures, wherein the reflecting layer, the infrared conversion structure and the columnar structures are located on the CMOS measuring circuit system. The infrared conversion structure comprises an absorption plate and a plurality of beam structures which are arranged on the same layer, the absorption plate comprises a thermosensitive layer and is perpendicular to the extending direction of the beam structures, and the width of each beam structure is smaller than or equal to 0.3 micrometer. The problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved. The closed release isolation layer in the CMOS infrared sensing structure reduces the release difficulty of the sacrificial layer and improves the detection sensitivity of the infrared detector.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Infrared detector mirror image pixel and infrared detector based on CMOS process

ActiveCN113720476APromote the development of miniaturizationIncreased radiation absorptionPyrometry using electric radation detectorsEngineeringReflective layer

The invention relates to an infrared detector mirror image pixel and an infrared detector based on a CMOS process, the mirror image pixel comprises a CMOS measurement circuit system and a CMOS infrared sensing structure which are both prepared by using the CMOS process, and the CMOS infrared sensing structure is directly prepared on the CMOS measurement circuit system; the CMOS infrared sensing structure comprises a reflecting layer, an infrared conversion structure and a first columnar structure, and the infrared conversion structure is electrically connected with the CMOS measuring circuit system through the first columnar structure and the supporting base; the beam structure is located on the side, close to the CMOS measurement circuit system, of the absorption plate, the absorption plate comprises a metal structure close to or away from the side, close to or away from the CMOS measurement circuit system, of the CMOS measurement circuit system, and at least part of the reflection plate is located in the orthographic projection of the metal structure. According to the technical scheme, the problems that a traditional MEMS process infrared detector is low in performance, low in pixel scale, low in yield and the like are solved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com