Method and device for controlling winding length of motor stator coil type coil

A technology of motor stator and control device, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as failure to meet design requirements at turns, failure to meet design size requirements, increased labor cost, etc. The effect of low strength, tight coil winding, and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The winding length control method of the high-voltage motor stator coil coil uses a coil winding machine for coil coil winding. When the stator coil is wound on the coil winding machine, firstly, the copper coil wires are hoisted on the wire coils in sequence according to the coil technical requirements. On the bracket, fix the copper wires side by side with an aggregator and adjust the tension of the wires; fix the winding mold on the winding machine, and the winding mold will leave a copper wire rebound of 1-3mm at the end of the lead nose to control Winder speed for coil winding. When winding the coil, flatten the wire so that it is close to the side of the winding core, so that the inside and outside of the wire are tightly wound and the gap between the coil noses is reduced.

[0029] Specific implementation process control:

[0030] The stator coil of the high-voltage motor is wound on the winding machine. First, according to the technical requirements of the desi...

Embodiment 2

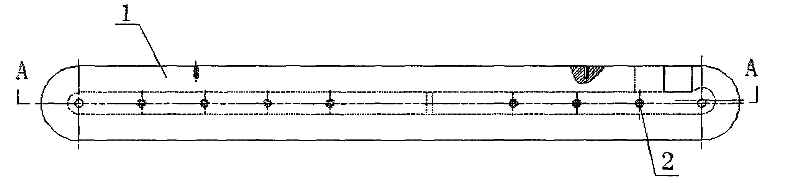

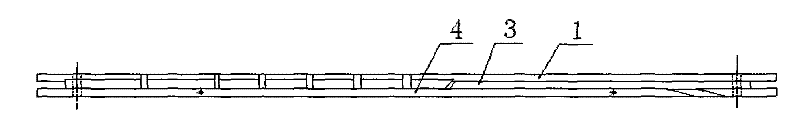

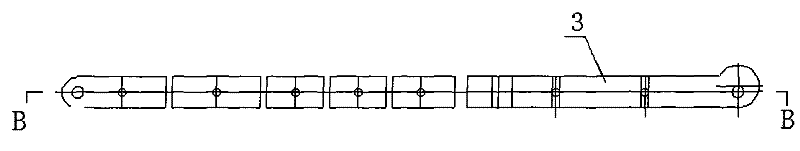

[0035] The high-voltage motor stator coil 5 winding length control device is fixed on the winding machine. The winding mold is an adjustable structure, including the inner baffle 1, the outer baffle 4 and the mold core 3. The mold core 3 is placed in the inner baffle Between the plate 1 and the outer baffle 4, the mold core 3 has an inner mold core and an outer mold core. The inner mold core is designed into two sections. The outer baffle is made with a guide rail structure, and the straight part can be adjusted. The inner baffle plate 1, the outer baffle plate 4 and the mold core 3 are fixed into an integral structure by countersunk head screws 2.

[0036] Concrete implementation operation process of the present invention:

[0037] Coil coil winding production process: 1) Adjust the size of the adjustable winding die according to the requirements of the design drawings, install it on the winding machine, and adjust the speed of the winding machine. 2) Place the copper coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com