Automatic slag removal mechanism of welding torch of full-automatic CO2 (carbon dioxide) welding machine

A welding machine and fully automatic technology, applied in the field of welding torch, can solve the problems of inability to effectively protect the weld bead from oxidation, carbon dioxide cannot be ejected smoothly, and low work efficiency, and achieve simple structure, prevent welding torch from clogging, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

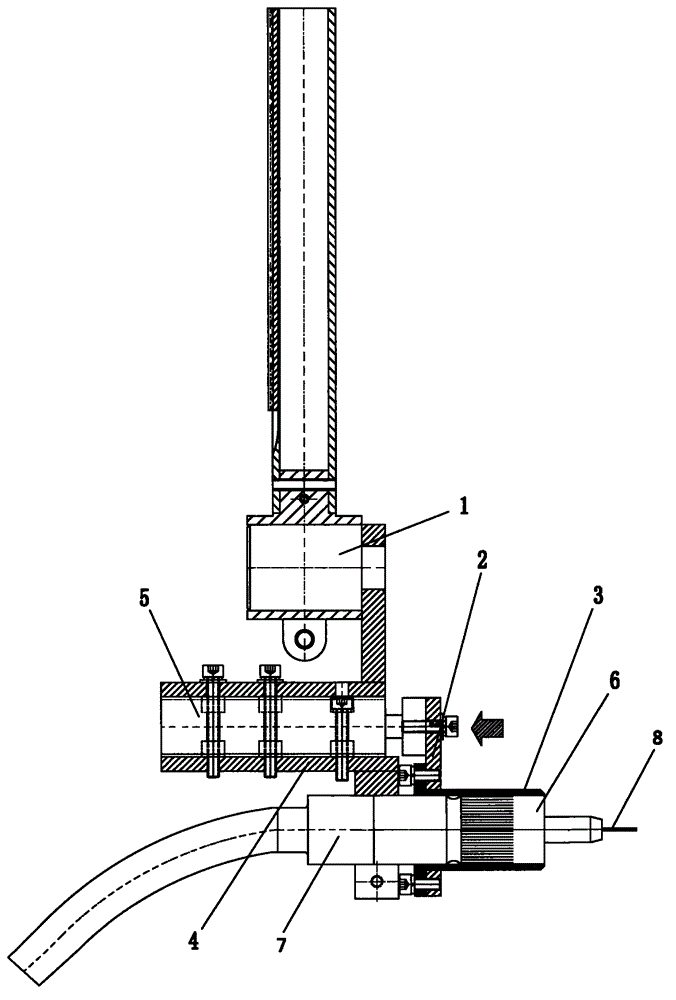

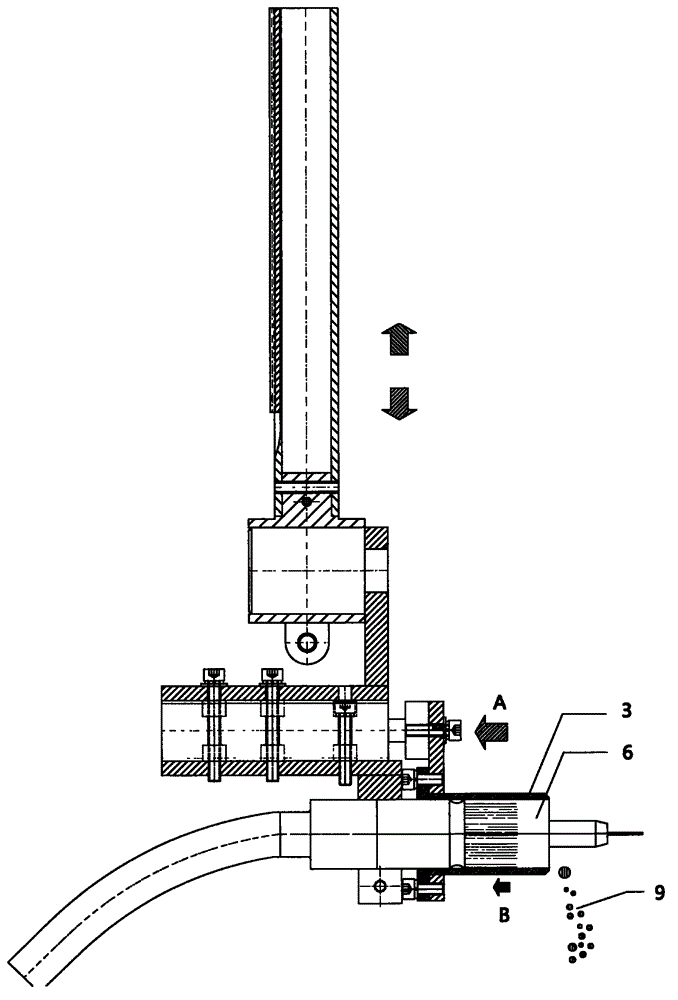

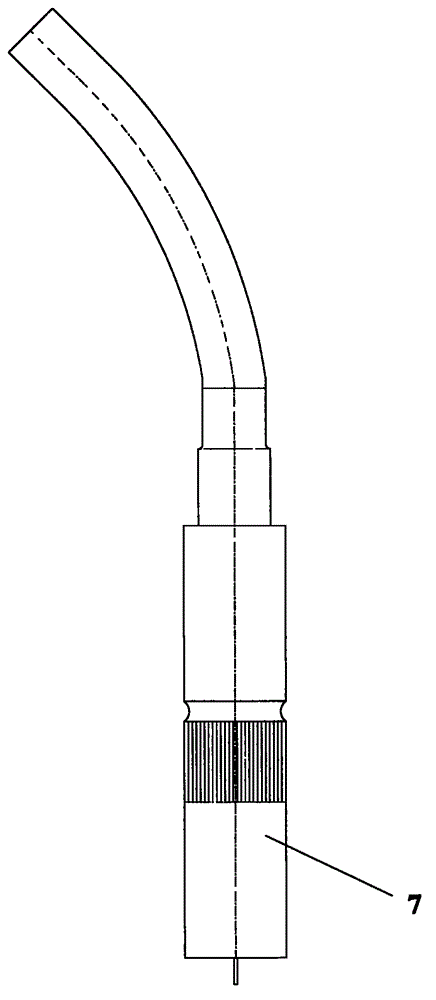

[0021] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and a preferred embodiment.

[0022] refer to Figure 1-3 Shown is a preferred embodiment of the present invention, which involves a CO 2 The standard welding torch (abbreviation welding torch 7) of the welding machine has a carbon dioxide inner protective cover 6 at the welding wire outlet end of the welding torch, and its outer circumference is equipped with a carbon dioxide outer protective cover 3, and the carbon dioxide outer protective cover 3 is fixed on the outer protective cover seat 2. The outer protection cover seat 2 is connected on the welding torch cylinder 5, the welding torch clamp 4 is equipped with the welding torch cylinder 5 lower sides, the welding torch clamp 4 is equipped with a carbon dioxide protection welding torch, and the outer circumference of the carbon dioxide inner protection cover 6 of its front end is covered wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com