Honing machine

A technology for honing machines and machine tools, which is applied in honing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. Small impact, improved safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

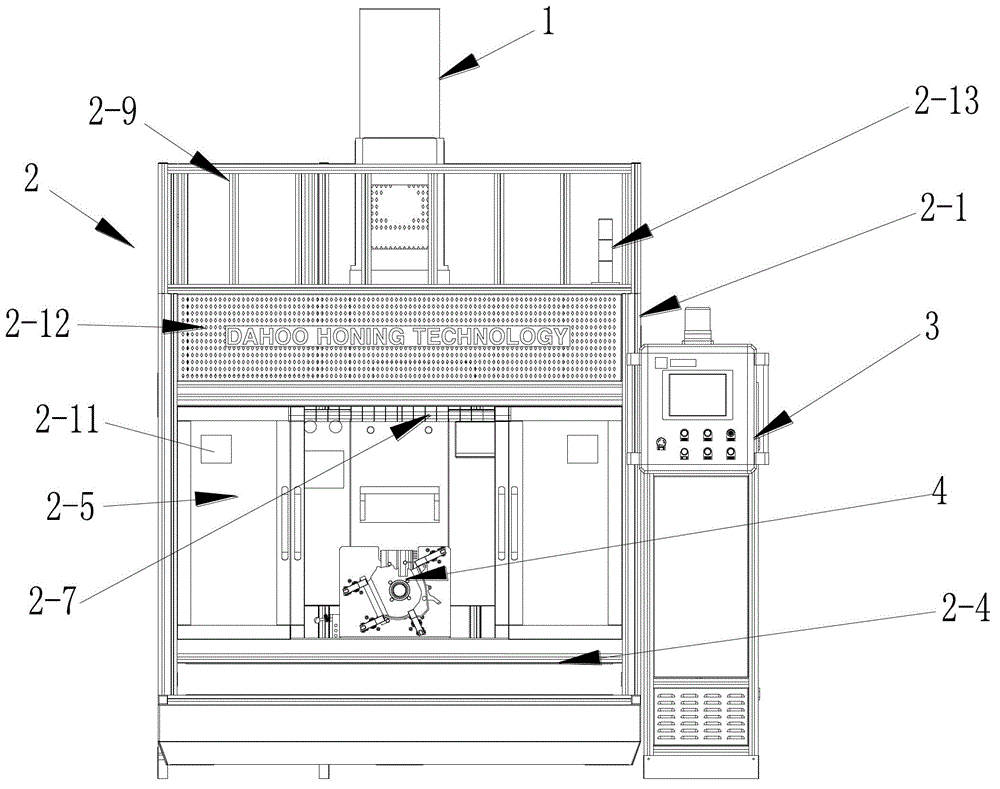

[0036] Such as Figure 1 to Figure 6 As shown, the same as the traditional honing machine, the honing machine provided by this embodiment also includes two major parts of the machine tool 1 and the machine tool control cabinet 3 . When working, the honing machine will rotate and reciprocate to grind the hole surface of the workpiece 4 to be processed, so that the hole of the workpiece 4 can obtain various technical requirements such as size, shape tolerance, surface roughness and surface texture.

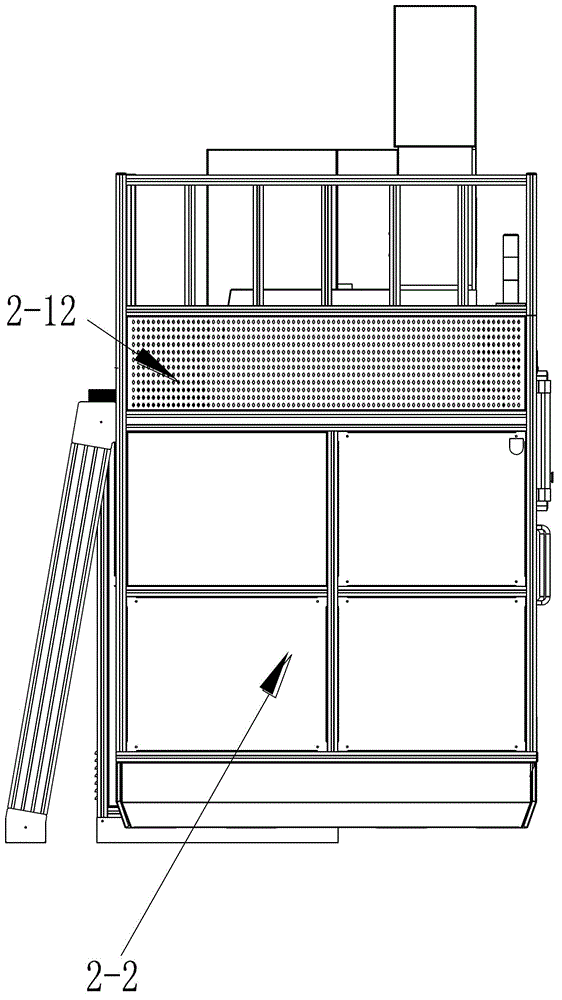

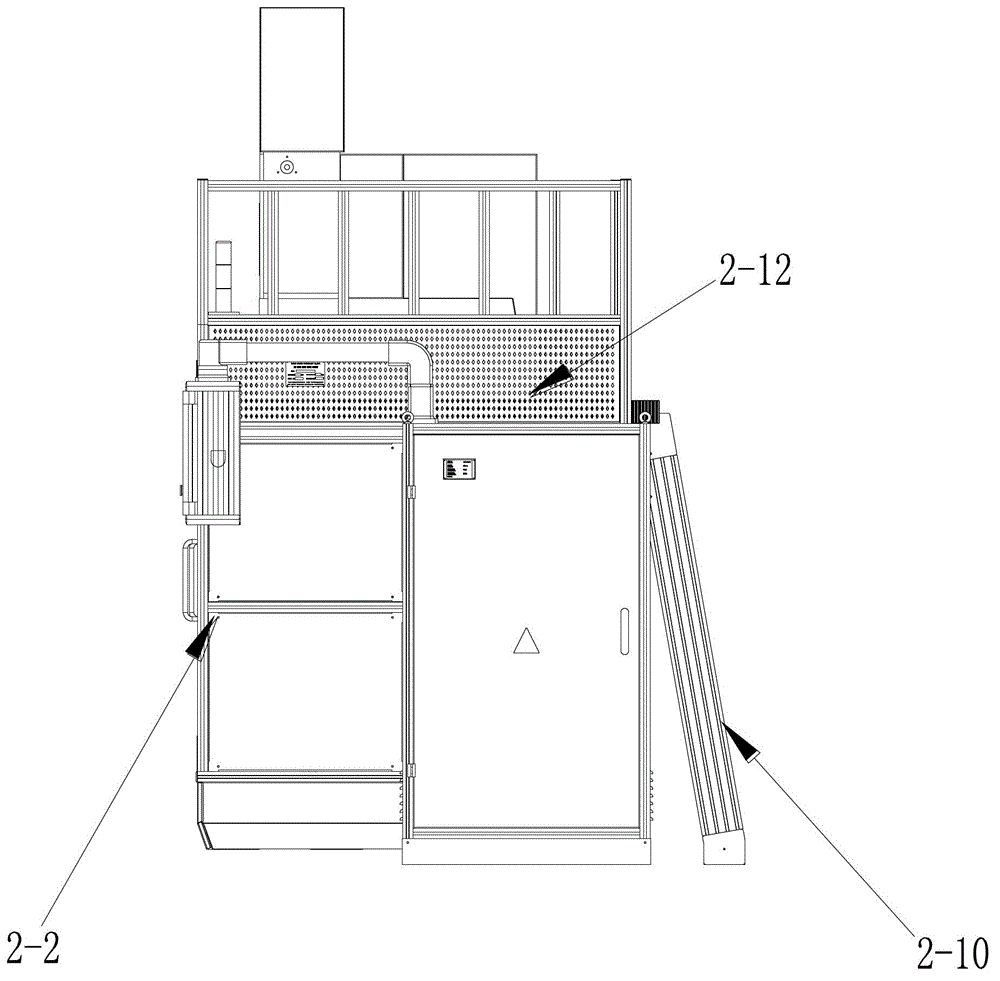

[0037] The key improvement of this embodiment is that the honing machine of this embodiment also includes a machine tool guard 2 covering the machine tool 1, and in this example the outer contour of the machine tool guard 2 is square.

[0038] Such as figure 1 As shown, the machine tool protective cover 2 includes a protective cover frame 2 - 1 erected outside the machine tool 1 , and the inner space of the protective cover frame 2 - 1 contains the entire honing processing area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com