Dendriform water treatment filler

A water treatment and dendritic technology, applied in the field of dendritic water treatment fillers, can solve the problems of pollution, affect the appearance, easy to break, etc., and achieve the effect of improving the specific surface area, increasing the film hanging space, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated below.

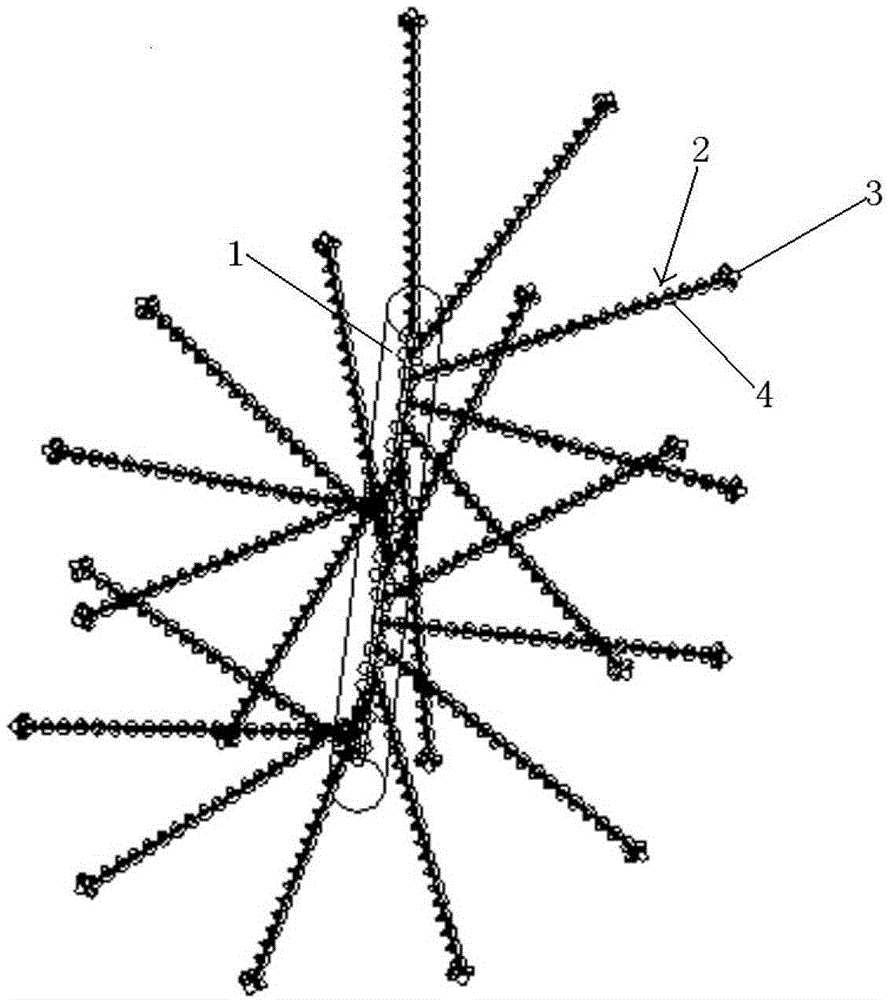

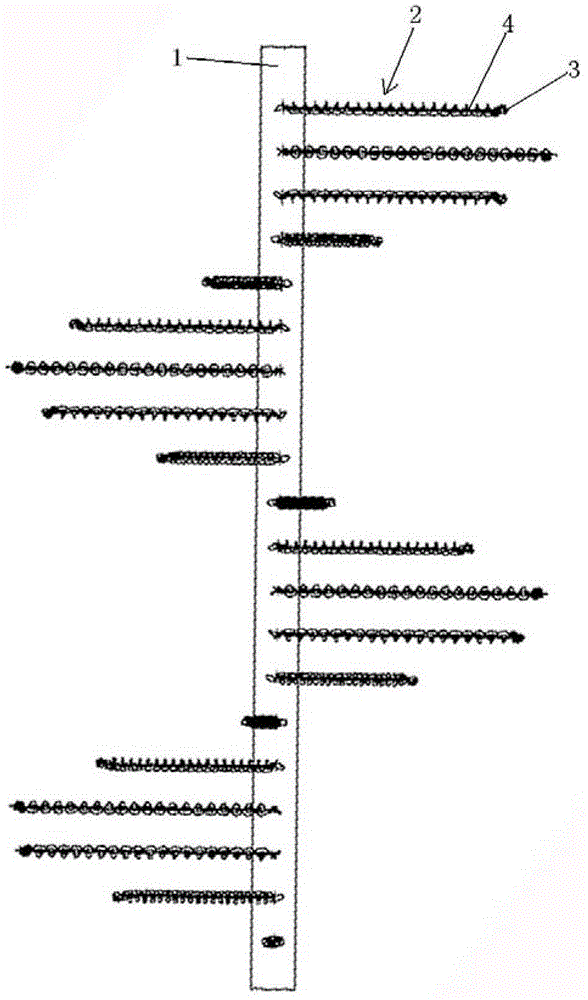

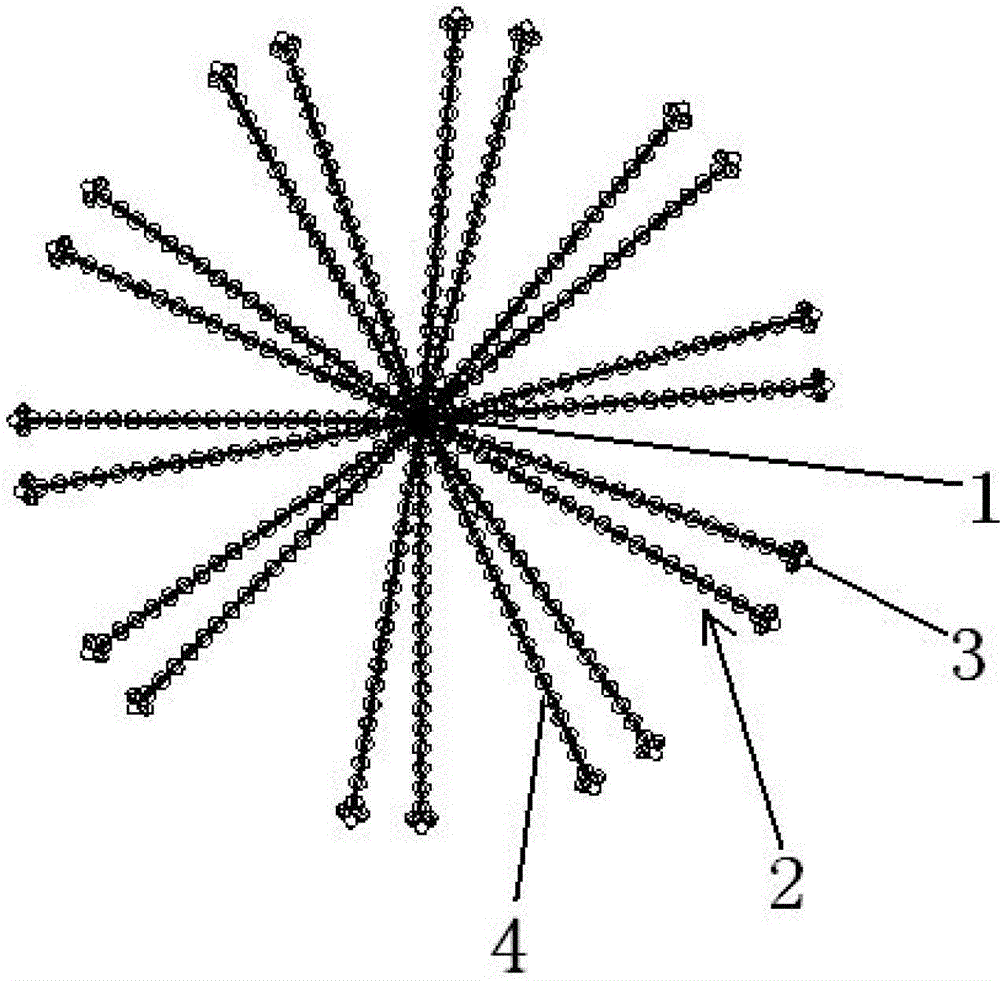

[0022] As shown in the accompanying drawings, a dendritic water treatment filler includes a middle rope 1, a plurality of fiber monomers 2 fixed on the middle rope 1, the fiber monomer 2 includes a fiber thread 4, and the fiber monomer 2 also includes a The axis 3 fixedly connected to the middle rope 1, the fiber thread 4 is wound on the axis 3, and the ends of the axis 3 and the fiber thread 4 are fixed in the middle rope 1 by braiding, the axis 3 is one or more strands, and the two ends of each strand are Fixed in the middle rope 1 by weaving, the material of the axis 3 is any one of aramid fiber, polypropylene fiber, polyethylene fiber and polyacrylonitrile fiber. When weaving, the axis 3 is first folded in half, and the axis 3 forms a ring at the folded point. The fiber thread 4 starts to wind on the axis 3 from the bottom of the ring, and wraps around the middle rope 1, and then the axis 3 and the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com