A molding process of a high-density large-size azo target blank

A technology with high density target body, which is applied in metal material coating process, ion implantation plating, coating, etc. It can solve the problems of uneven density, uneven force, and difficult production, so as to increase the density and tissue uniformity, simple process operation, and the effect of increasing the solid phase volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

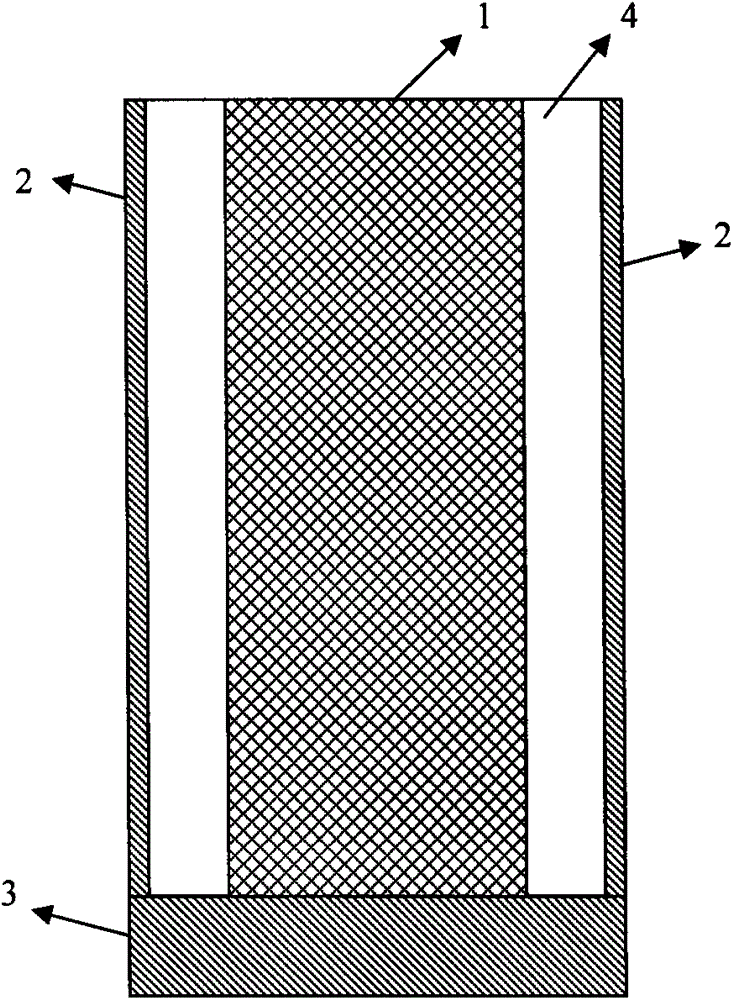

[0030]Mix 5kg (kilograms) of zinc oxide and aluminum oxide superfine powder, wherein the aluminum oxide superfine powder accounts for 2wt% (mass fraction) of the total mass of the mixed powder, and after spray drying and granulation, AZO with an average particle size of about 10 μm (micron) is obtained. Powder, fluidity 60s (seconds) / 50g (grams), put the granulated powder into a ball mill jar equipped with 10kg (kilograms) of corundum balls, add 40g (grams) of propylene to 1L (liters) of deionized water Amide, 10g (grams) gum arabic powder, 50g (grams) absolute ethanol, after stirring completely, the mixed solution is added in the ball milling jar, the ball milling jar is sealed, and it is vacuumized, and the roller ball milling is 2h (hour), in a vacuum The prepared slurry is poured into the attached figure 1 In the mold shown, after pouring is completed, it is immediately moved into a constant temperature and humidity box for drying and molding. After drying to constant weig...

Embodiment approach 2

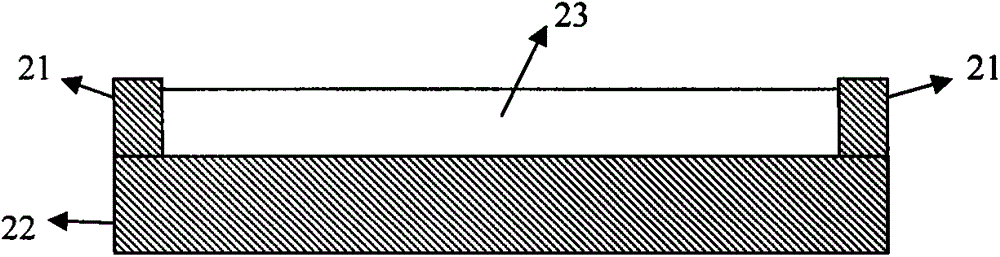

[0032] Mix 5kg (kilograms) of zinc oxide and aluminum oxide superfine powder, wherein the aluminum oxide superfine powder accounts for 1wt% (mass fraction) of the mixed powder mass, and after spray drying and granulation, AZO mixed with an average particle size of about 7 μm (micron) is obtained. Powder, fluidity 73s (second) / 50g (gram), the powder after granulation is added in the ball mill jar that 10kg (kilogram) corundum ball is housed, add 40g (gram) propylene to 950mL (milliliter) deionized water Amide, 15g (grams) gum arabic powder, 60g (grams) absolute ethanol, after stirring completely, the mixed solution is added in the ball milling jar, the ball milling jar is sealed, and it is vacuumized after roller ball milling for 3h (hour), in a vacuum The prepared slurry is poured into the attached figure 2 In the mold shown, after pouring is completed, it is immediately moved into a constant temperature and humidity box for drying and molding. After drying to constant weight...

Embodiment approach 3

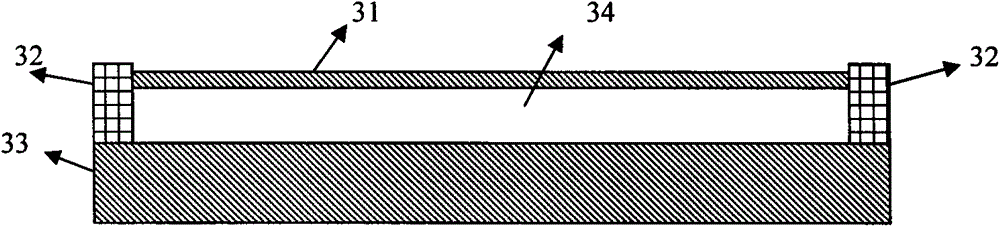

[0034] Mix 5kg (kilograms) of zinc oxide and aluminum oxide superfine powder, wherein the aluminum oxide superfine powder accounts for 3wt% (mass fraction) of the mixed powder mass, and after spray drying and granulation, AZO mixed with an average particle size of about 5 μm (micron) is obtained. Powder, fluidity 80s (second) / 50g (gram), add the powder after granulation into a ball mill jar equipped with 10kg (kilogram) corundum balls, add 40g (gram) propylene to 900mL (milliliter) deionized water Amide, 15g (grams) gum arabic powder, 80g (grams) absolute ethanol, after stirring completely, the mixed solution is added in the ball milling tank, the ball milling tank is sealed, and it is vacuumized after roller milling for 5h (hour), in a vacuum The prepared slurry is poured into the attached image 3 In the mold shown, after pouring is completed, it is immediately moved into a constant temperature and humidity box for drying and molding. After drying to constant weight in an en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com