Silicon rubber for high-temperature-resistant mold and preparation method of silicon rubber

A silicone rubber, high temperature resistant technology, applied in high temperature resistant mold silicone rubber and its preparation, silicone rubber and its preparation field, can solve the problems affecting product qualification rate, low production efficiency, surface cracking, etc., to inhibit oxidation aging, The effect of prolonging the service life and slowing down the aging rate at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of silicone rubber for high temperature resistant molds, the preparation steps are as follows: 100 parts of methyl vinyl silicone rubber raw rubber, 10 parts of methyl vinyl phenyl silicone rubber raw rubber, 20 parts of fumed white Add carbon black, 2 parts of hydroxy silicone oil and 0.17 parts of zinc stearate into the vacuum kneader for kneading. After the materials are kneaded into a ball, raise the temperature to 160°C, keep the temperature at this temperature for 2 hours, and then evacuate to the vacuum degree. It is -0.05MPa, after vacuuming for 30 minutes, the glue is released, and then 1 part of silicone resin and 1 part of nano-cerium oxide are added to the rubber on the double-roller mill for mixing, and finally filtered on the rubber filter, that is The silicone rubber for the high temperature resistant mold can be obtained.

Embodiment 2

[0023] A preparation method of silicone rubber for high temperature resistant molds, the preparation steps are as follows: 100 parts of methyl vinyl silicone rubber raw rubber, 10 parts of methyl vinyl phenyl silicone rubber raw rubber, 40 parts of fumed white Add carbon black, 6 parts of hydroxy silicone oil and 0.18 parts of zinc stearate into a vacuum kneader for kneading. After the materials are kneaded into a ball, heat up to 165°C, keep the temperature at this temperature for 2.5 hours, and then evacuate to a vacuum. The density is -0.06MPa, after vacuuming for 40 minutes, the rubber is released, and then 2 parts of silicone resin and 3 parts of nano-cerium oxide are added to the rubber on the double-roller mill for mixing, and finally filtered on the rubber filter. The silicone rubber for the high temperature resistant mold can be obtained.

Embodiment 3

[0025] A preparation method of silicone rubber for high temperature resistant molds, the preparation steps are as follows: 100 parts of methyl vinyl silicone rubber raw rubber, 10 parts of methyl vinyl phenyl silicone rubber raw rubber, 60 parts of fumed white Add carbon black, 8 parts of hydroxy silicone oil and 0.2 parts of zinc stearate into the vacuum kneader for kneading. After the materials are kneaded into a ball, heat up to 170°C, keep the temperature at this temperature for 3 hours, and then evacuate to vacuum It is -0.07MPa, after evacuating for 60 minutes, the glue is released, and then 4 parts of silicone resin and 4 parts of nano-cerium oxide are added to the rubber on the double-roller mill for mixing, and finally filtered on the rubber filter, that is The silicone rubber for the high temperature resistant mold can be obtained.

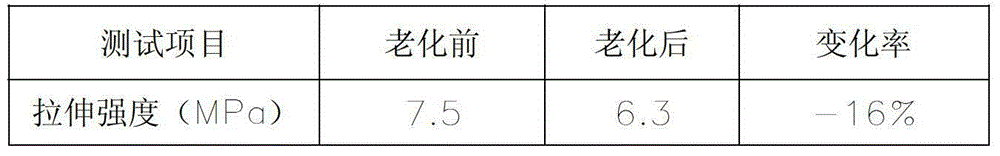

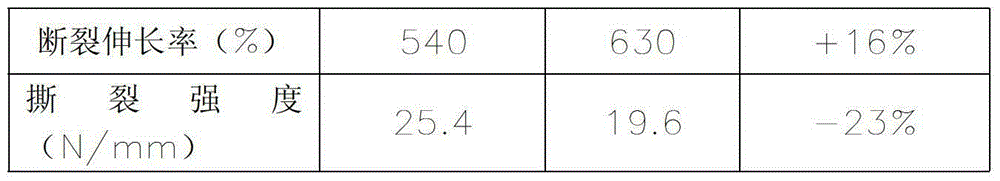

[0026] Add the liquid vulcanizing agent bis(2,4-dichlorobenzoyl peroxide) to the prepared high-temperature-resistant mold with silicone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com