Method for harvesting microalgae with magnetic separator

A magnetic separator and magnetic separation technology, applied in the field of harvesting microalgae by magnetic separator, using magnetic separator to realize rapid and efficient harvesting of microalgae, can solve the problem of high cost of microalgae harvesting, complicated operation process, small scale, etc. problem, to achieve the effect of simple structure, small size and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 magnetic separator is used for the harvesting of chlorella

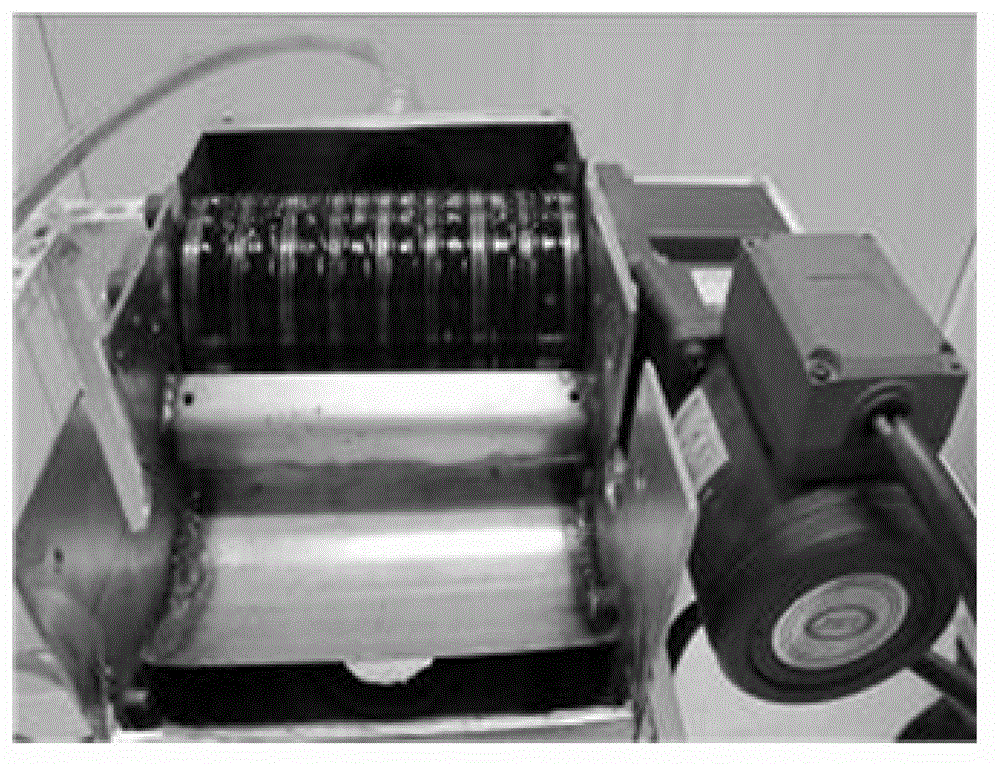

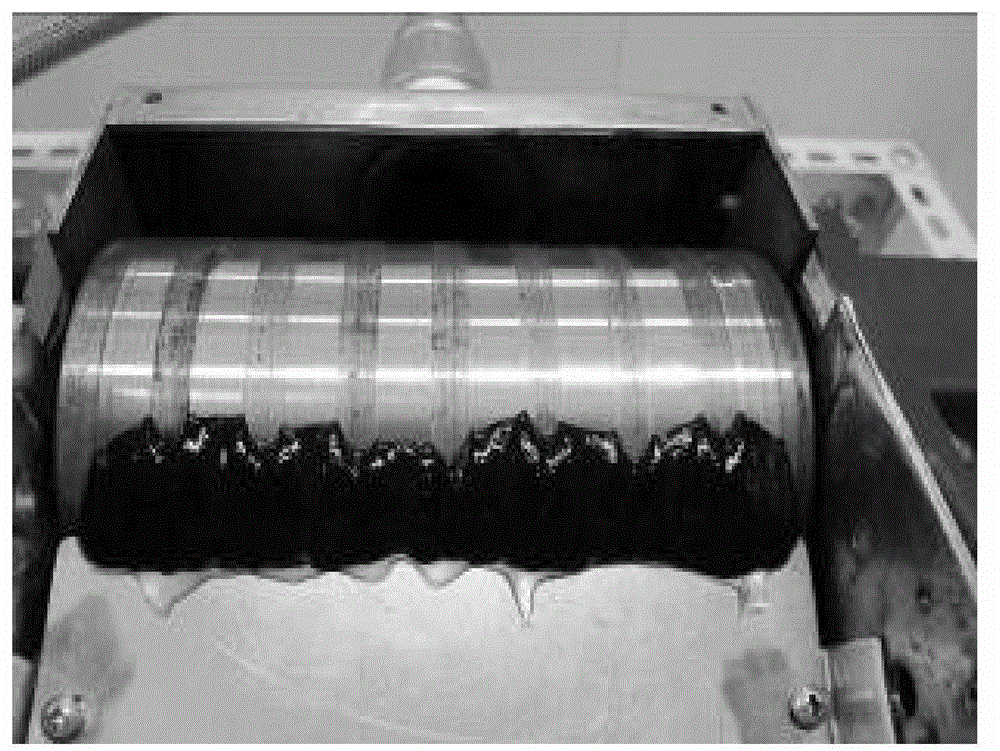

[0044] Add magnetic iron ferric oxide nanoparticles to the chlorella culture solution with a concentration of 0.5g / L, stir to mix the magnetic iron ferric oxide nanoparticles and the microalgae culture solution evenly, and pump the mixed solution into the magnetic separator. Stop feeding when the mixed liquid fills the magnetic separation tank, and adopt the intermittent magnetic separation method for magnetic separation. The magnetic separation time of each cycle is 10s. When the thickness reaches 30mm (such as figure 1 shown), the magnetic drum of the rotating magnetic separator, the Fe3O4 nanoparticle-microalgae complex is scraped off by the scraper (such as figure 2 shown), the recovery efficiency of Chlorella reached 95%.

Embodiment 2

[0045] Embodiment 2 magnetic separator is used for the harvesting of chlorella

[0046]Add polyethyleneimine-modified ferric oxide nanoparticles to the chlorella culture solution with a concentration of 9g / L to form a mixed solution with a material concentration of 10g / L, and stir to mix the magnetic nanoparticles and the microalgae culture solution evenly , the mixed solution is pumped into the magnetic separator, and the continuous magnetic separation method is used for magnetic separation. The flow rate of the feed liquid is 8000mL / min, and the rotation speed of the magnetic drum is 100rpm. The algae complex is scraped off by the scraper along with the rotation of the magnetic drum, and the chlorella is collected, and the recovery efficiency of the chlorella reaches 96%.

Embodiment 3

[0047] Embodiment 3 magnetic separator is used for the harvesting of chlorella

[0048] Add polyethyleneimine-modified iron ferric oxide nanoparticles to the chlorella culture solution with a concentration of 90g / L to form a mixed solution with a material concentration of 150g / L, and stir to mix the magnetic nanoparticles and the microalgae culture solution evenly , the mixed solution is pumped into the magnetic separator, and the continuous magnetic separation method is used for magnetic separation. The flow rate of the feed liquid is 100mL / min, and the rotation speed of the magnetic drum is 10rpm. The algae complex is scraped off by the scraper along with the rotation of the magnetic drum, and the chlorella is collected, and the recovery efficiency of the chlorella reaches 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com