Converter gas dry method bag-type recovering and purifying process system

A purification process and converter gas technology, which is applied in the field of converter gas full dry bag type recovery and purification process system to achieve the effects of increasing calorific value, operating safely and stably, and preventing explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

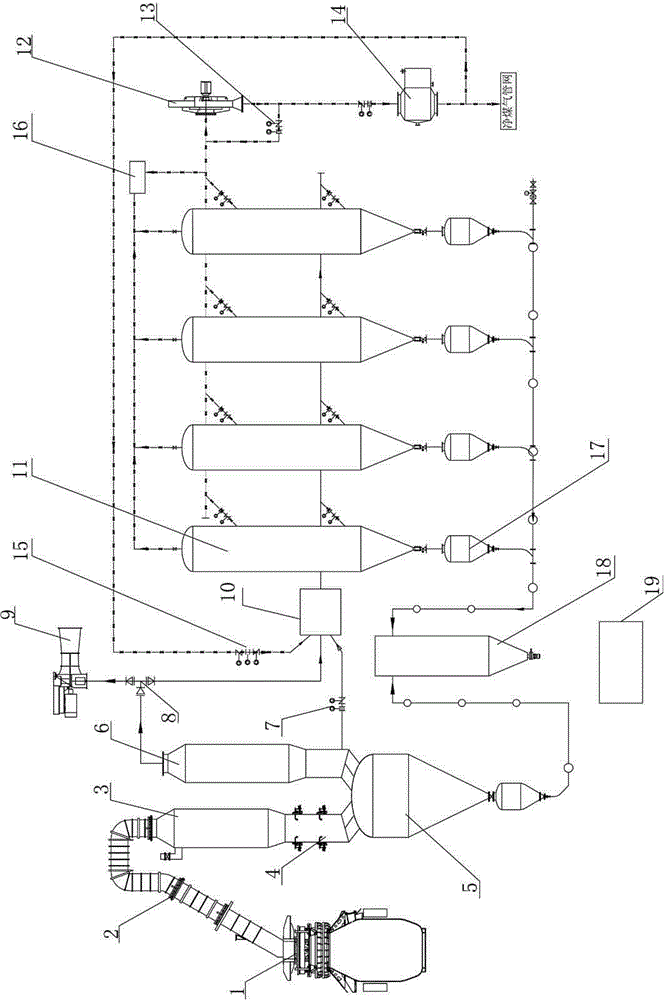

[0011] like figure 1 As shown, a converter gas full-dry bag recovery and purification process system consists of a waste heat boiler (1), a water-cooled flue (2), a first-stage waste heat boiler (3), an atomizing cooler (4), and an ash cooler (5), secondary waste heat boiler (6), heating valve group (7), three-way switching valve (8), bypass fan (9), gas mixer (10), several dry bag filter (11 ), gas fan (12), low-speed operation valve group (13), clean gas cooler (14), cooling valve group (15), explosion venting device (16), fully enclosed ash conveying device (17), ash storage bin (18) and control system (19).

[0012] The outlet of the waste heat boiler (1) is connected to the water-cooled flue (2), the outlet of the water-cooled flue (2) is connected to the primary waste heat boiler (3), the outlet of the primary waste heat boiler (3) is connected to the atomizing cooler (4), and the atomizing cooling The outlet of the boiler (4) is connected to the inlet of the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com