Process utilizing sheet billet continuous casting to manufacture low aluminum silicon calm carbon structural steel

A technology of thin slab continuous casting and silicon-killed carbon, which is applied in the field of iron and steel smelting technology, can solve the problems of long production cycle, increased manufacturing cost, and excess product functions, and achieve excellent quality, small liquid level fluctuations, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further illustrated by the following examples.

[0014] In the embodiment, the process flow for producing low-aluminum-silicon killed carbon structural steel by thin slab short process is: blast furnace hot metal→converter smelting→LF refining→thin slab continuous casting.

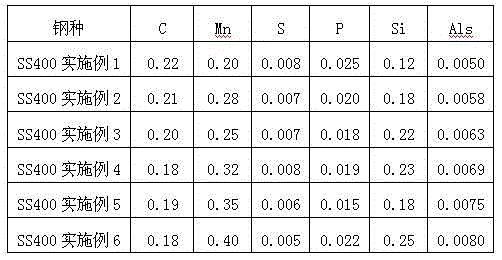

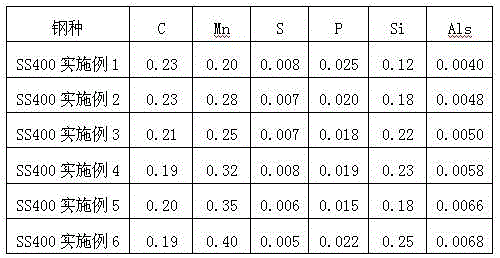

[0015] Example converter 150t, LF refining 150t, thin slab continuous casting: continuous casting slab width 1250-1500mm, thickness 65mm, production of low-aluminum silicon killed carbon structural steel, a total of six examples.

[0016] The specific operation steps and process parameter control of each process are as follows:

[0017] (1) Converter smelting process

[0018] a. The temperature of molten iron is 1350℃, S=0.030%, P=0.120%;

[0019] b. The main goal of the conversion process is dephosphorization, and the slagging process is required to increase the furnace temperature steadily;

[0020] c. Final slag basicity R is 3.0-3.5, molten steel composition (mass percentage) C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com