Small-gap and low-friction piston component

A piston assembly, low-friction technology, applied to pistons, pump components, engine components, etc., can solve problems such as reduced mechanical efficiency, air tightness leakage, etc., to reduce exhaust emissions, increase compression pressure, and improve combustion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

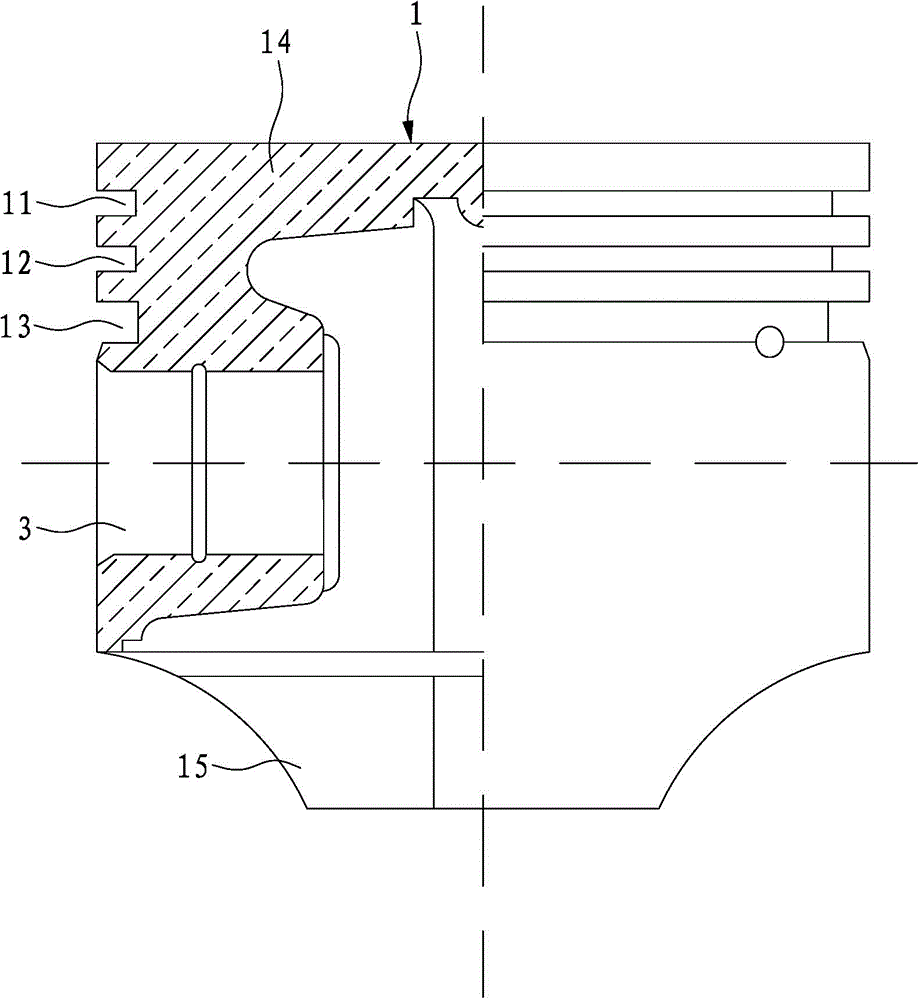

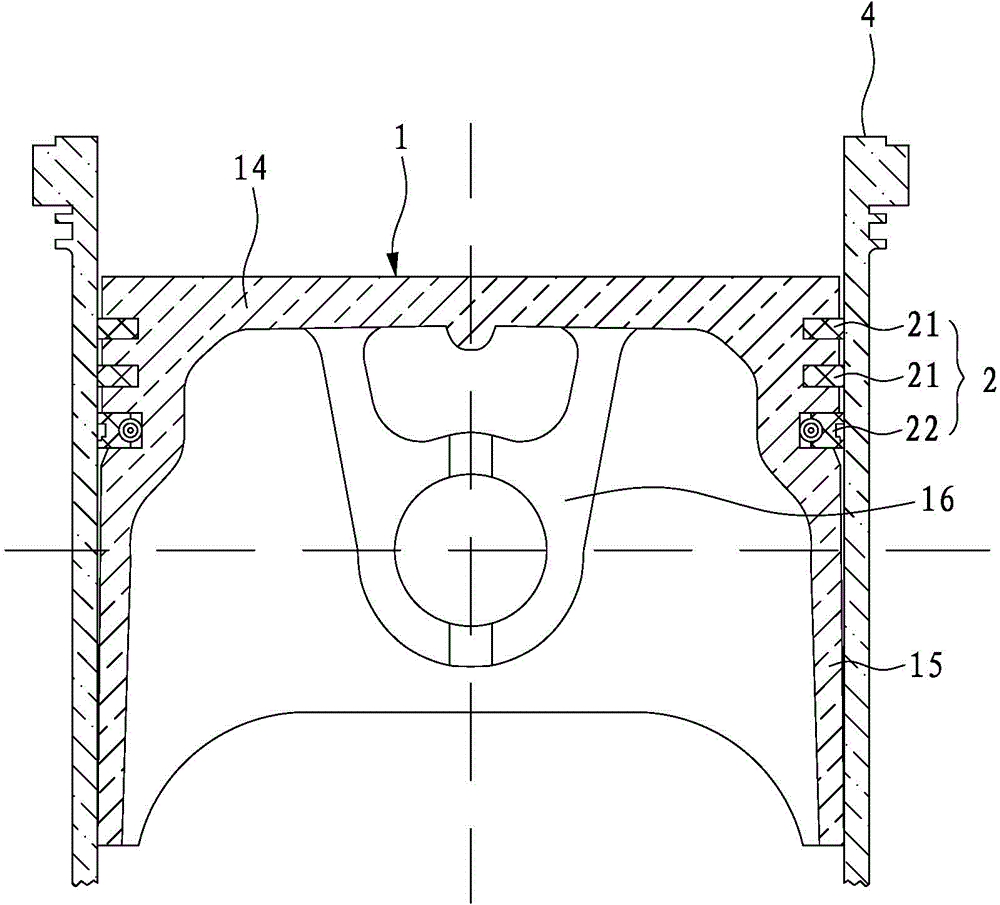

[0029] refer to Figure 1 to Figure 3 As shown, a small clearance, low friction piston assembly disclosed by the present invention includes a piston 1 , a piston ring 2 , a piston pin 3 and a cylinder liner 4 .

[0030] Among them, the piston ring 2 includes an air ring 21 and an oil ring 22. In this embodiment, two air rings 21 and one oil ring 22 are provided. Correspondingly, three ring grooves (11, 12, 13) are formed on the piston 1, located at The upper two annular grooves (11, 12) are equipped with gas rings 21 for heat transfer and sealing, while the lowermost annular groove 13 is installed with oil rings 22 for oil distribution and oil scraping.

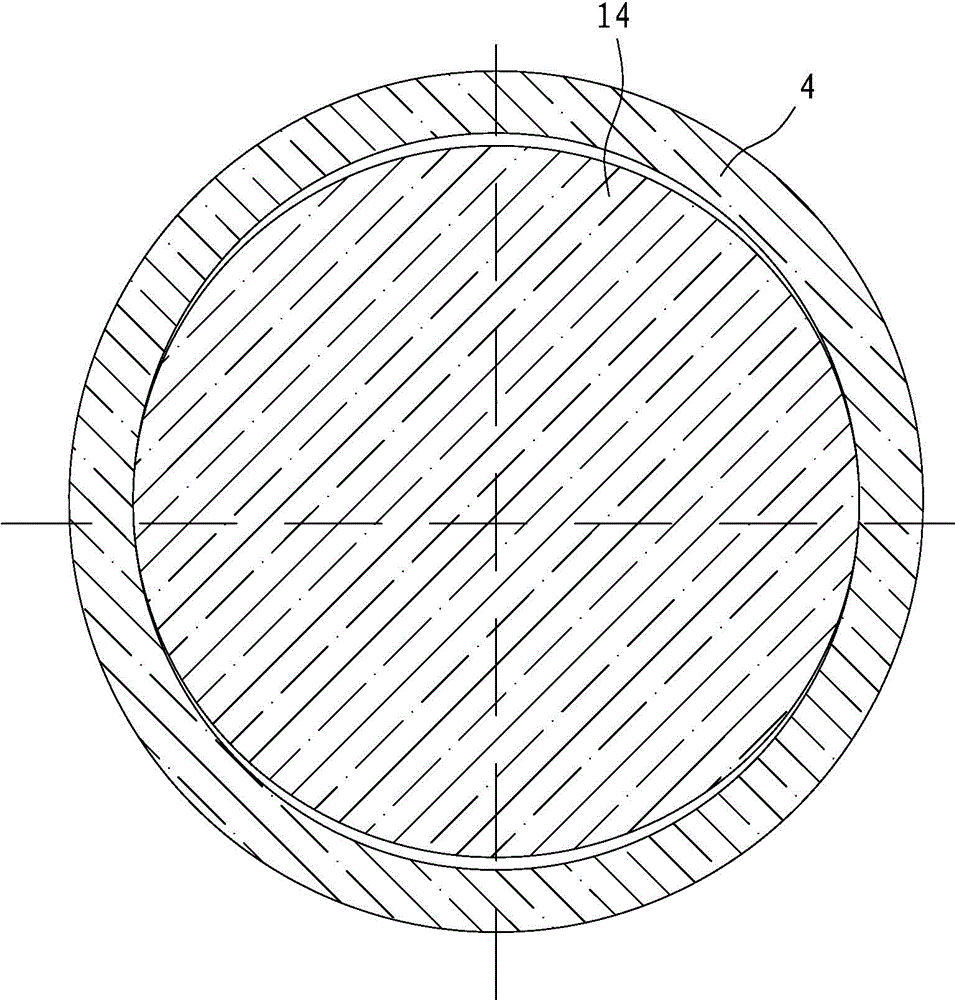

[0031] Piston 1 is made up of head 14 and skirt 15, and the cross section of piston 1 head 14 is ellipse, as image 3 As shown, the difference between the diameter of the major axis and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com