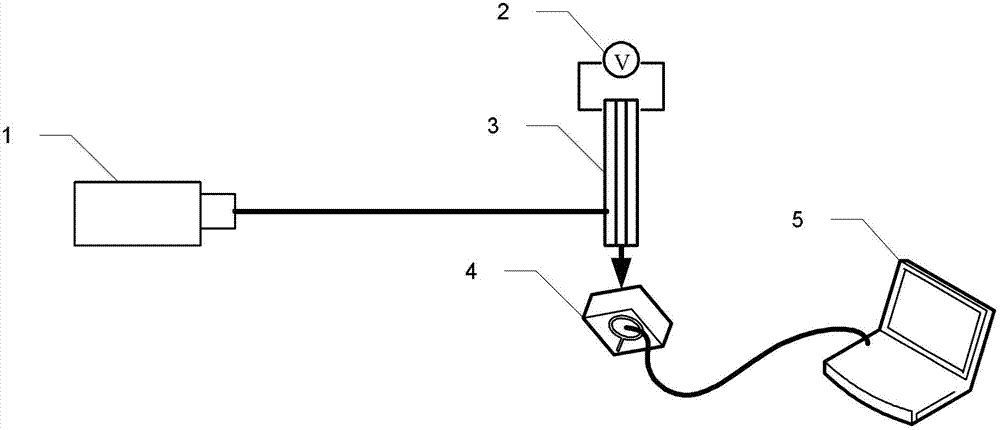

Liquid crystal cell with micro-groove structure and its manufacturing method, and method for controlling laser continuous tuning with voltage changes based on the liquid crystal cell

A voltage change and micro-groove technology, applied in lasers, laser parts, microlithography exposure equipment, etc., can solve problems such as poor wavelength tuning, and achieve the effect of expanding the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

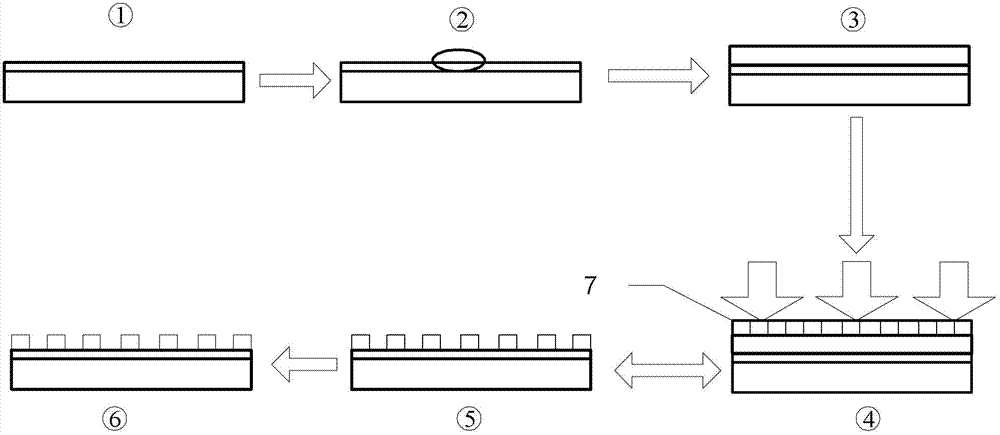

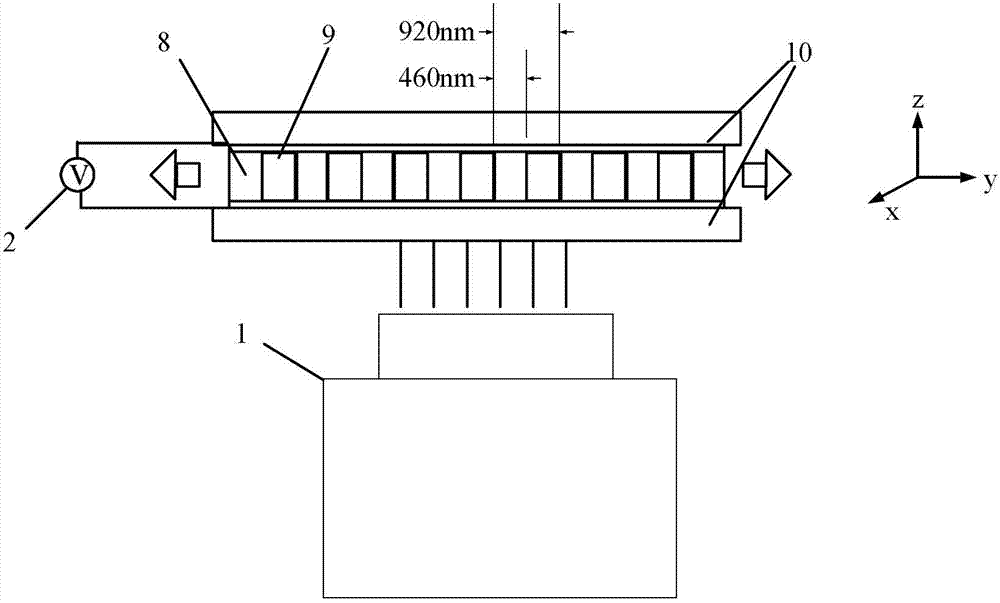

[0020] Specific implementation mode one: combine image 3 Describe this embodiment mode, the liquid crystal cell with microgroove structure described in this embodiment mode,

[0021] It includes two ITO glasses, multiple microgrooves and liquid crystals; multiple microgrooves parallel to each other are set between the two ITO glasses, and each microgroove is filled with liquid crystals.

specific Embodiment approach 2

[0022] Embodiment 2: This embodiment is a further limitation of the liquid crystal cell with a micro-groove structure described in Embodiment 1, where the micro-grooves are formed by photoresist.

specific Embodiment approach 3

[0023] Specific embodiment three: this embodiment is a further limitation of the liquid crystal cell with a micro-groove structure described in specific embodiment one, the ratio of the width of each micro-groove to the distance between two adjacent micro-grooves is 1 :1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com