Fermented milk with improved taste and manufacturing method thereof

A manufacturing method and technology of fermented milk, applied in dairy products, biochemical equipment and methods, enzymes, etc., can solve problems such as improving or not solving the taste of fermented milk, and achieve the effects of suppressing sourness, good sweet-acid balance, and increasing sweetness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

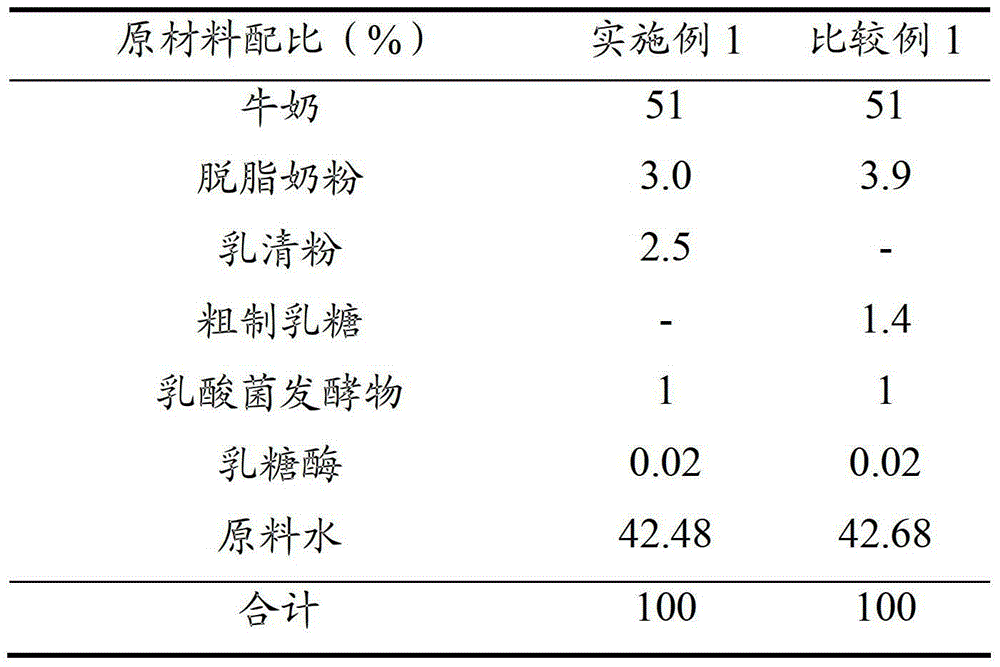

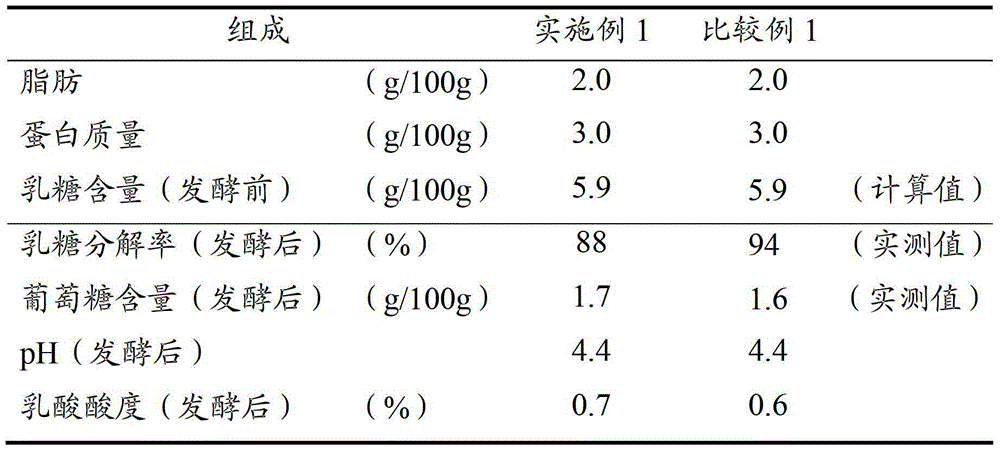

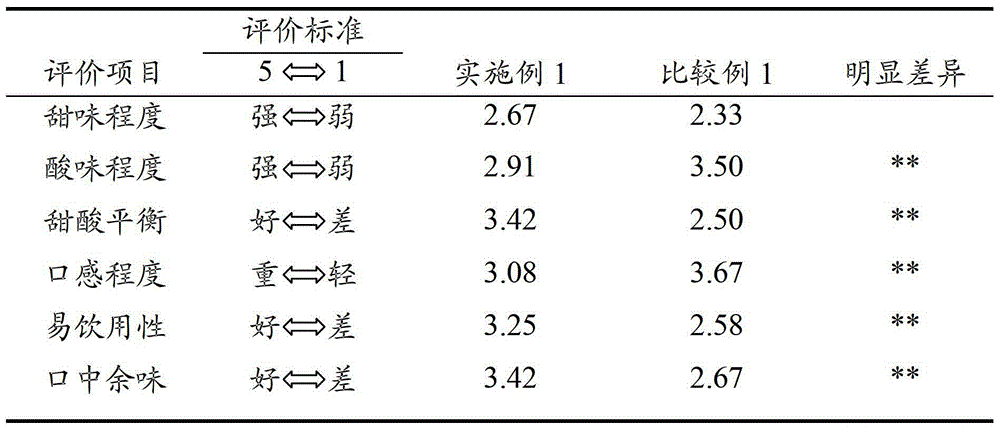

Embodiment 1

[0081] Skimmed milk powder with 1% fat content, 34% protein, 54% lactose (trade name: "Meiji Skim Milk", manufactured by Meiji Dairy Co.), milk with 3.9% fat content, 3.2% protein, and 4.7% lactose (trade name: "Meiji Milk", Meiji Dairy Co., Ltd.) and whey powder with 1.0% fat content, 12% protein, 76% lactose, 97% solid content, 8.6% ash, 0.7% sodium, 2.5% potassium (trade name: "Meiji" ホエイパウダー", Meiji Dairy Co., Ltd.) was prepared in the ratio shown in Table 1. Lactobacillus bulgaricus 2038 strain and thermophilic milk isolated from lactose decomposing enzyme (lactase) (trade name: "GODO-YNL", manufactured by contract alcohol) and lactic acid bacteria starter (Meiji Dairy Co., Ltd. "Meiji Bulgeria ヨーグルト" (trade name) Streptococcus 1131 strain) was added at the same time, fermented at 43°C until it reached pH 4.4 (about 3 hours), and the fermented milk curd formed was crushed and cooled with a filter. As a comparative control, crude lactose (lactose content 99.5%, trade name: ...

Embodiment 2

[0093] Skimmed milk powder with 1% fat content, 34% protein, 54% lactose (trade name: "Meiji Skim Milk", manufactured by Meiji Dairy Co.), milk with 3.9% fat content, 3.2% protein, and 4.7% lactose (trade name: "Meiji Milk", Meiji Dairy Co., Ltd.) and whey powder with 1.0% fat content, 12% protein, 76% lactose, 97% solid content, 8.6% ash, 0.7% sodium, 2.5% potassium (trade name: "Meiji" ホエイパウダー", Meiji Dairy Industry Co., Ltd.) was prepared in the ratio shown in Table 4. Lactose decomposing enzyme (lactase) (trade name: "GODO-YNL", manufactured by contract alcohol) and lactic acid bacteria starter (produced by Meiji Dairy Co., Ltd. "Meiji Bulgeria ヨーグルト" (trade name) isolated Lactobacillus bulgaricus strain 2038 and thermophilic Streptococcus lactis 1131 strain) was added at the same time, fermented at 43°C until it reached pH 4.4 (about 3 hours), and the fermented milk curd formed was crushed and cooled with a filter. As a comparative control, skimmed milk powder was used ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com