Low-temperature quenching method for medium-carbon steel workpiece

A low-temperature quenching and workpiece technology, applied in the field of quenching, can solve the problems of difficult control of steel deformation, easy deformation of steel, large internal stress, etc., and achieve the effect of workpiece quality up to standard and stable, control of shrinkage deformation, and reduction of internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

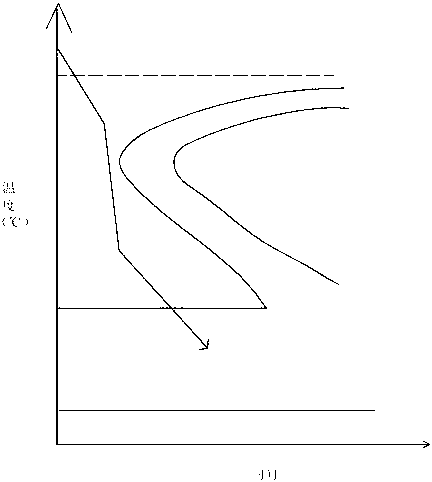

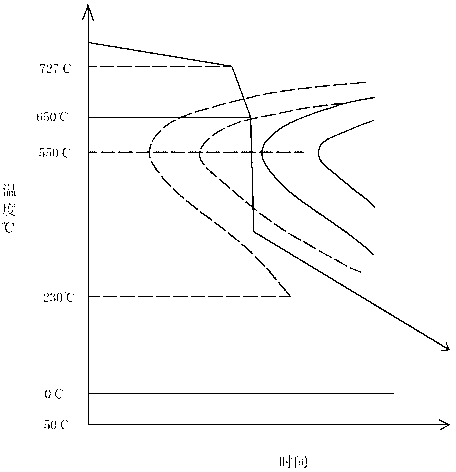

[0034] Such as Figure 5 Shown, according to the method for low-temperature quenching of medium carbon steel workpiece of the present invention, the step of 45# steel workpiece quenching is as follows:

[0035] (1) Heat the 45# steel workpiece to 840° in the mesh belt furnace, and heat preservation treatment after heating, so that the internal structure of the workpiece is transformed into a uniform unsaturated austenite structure;

[0036] (2) Cool the medium-carbon steel workpiece in a constant temperature state to 727°C by slow cooling method, and then cool the workpiece temperature from 727°C to 650°C at the sealing barrel. The interior of the workpiece is a supercooled austenite quenching structure;

[0037] (3) The workpiece leaves the sealed barrel and goes straight into the deep water area. The solution in the deep water area can be water or 251AQ quenching agent aqueous solution, and the water temperature in the deep water area is 28°C. The cooling process is that t...

Embodiment 2

[0039] According to the method for low-temperature quenching of carbon steel workpiece in the present invention, the step of 60# steel workpiece quenching is as follows:

[0040] (1) Heat the 60# carbon steel workpiece to 810° in the mesh belt furnace, heat preservation treatment after heating, and the internal structure of the workpiece is transformed into a uniform unsaturated austenite structure;

[0041] (2) Cool the medium-carbon steel workpiece in a constant temperature state to 727°C by slow cooling method, and then cool the workpiece temperature from 727°C to 650°C at the sealing barrel. The interior of the workpiece is a supercooled austenite quenching structure;

[0042] (3) The workpiece leaves the sealed barrel and goes straight into the deep water area. The solution in the deep water area can be water or 251AQ quenching agent aqueous solution, and the water temperature in the deep water area is 32°C. The cooling process is that the workpiece is rapidly cooled fro...

Embodiment 3

[0044] According to the method for low-temperature quenching of carbon steel workpiece in the present invention, the step of 25# steel workpiece quenching is as follows:

[0045](1) Heat the 25# carbon steel workpiece to 890° in the mesh belt furnace, and then perform heat preservation treatment after heating, so that the internal structure of the workpiece is transformed into a uniform unsaturated austenite structure;

[0046] (2) Cool the medium-carbon steel workpiece in a constant temperature state to 727°C by slow cooling method, and then cool the workpiece temperature from 727°C to 650°C at the sealing barrel. The interior of the workpiece is a supercooled austenite quenching structure;

[0047] (3) The workpiece leaves the sealed barrel and goes straight into the deep water area. The solution in the deep water area can be water or 251AQ quenching agent aqueous solution, and the water temperature in the deep water area is 32 °C. The cooling process is that the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com