Oil metal abrasive particles online monitoring system

A monitoring system, metal abrasive particle technology, applied in the direction of measuring devices, particle suspension analysis, suspension and porous material analysis, etc., can solve the problem of high cost measurement sample points, etc., to avoid engine accidents, high measurement accuracy, real-time Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

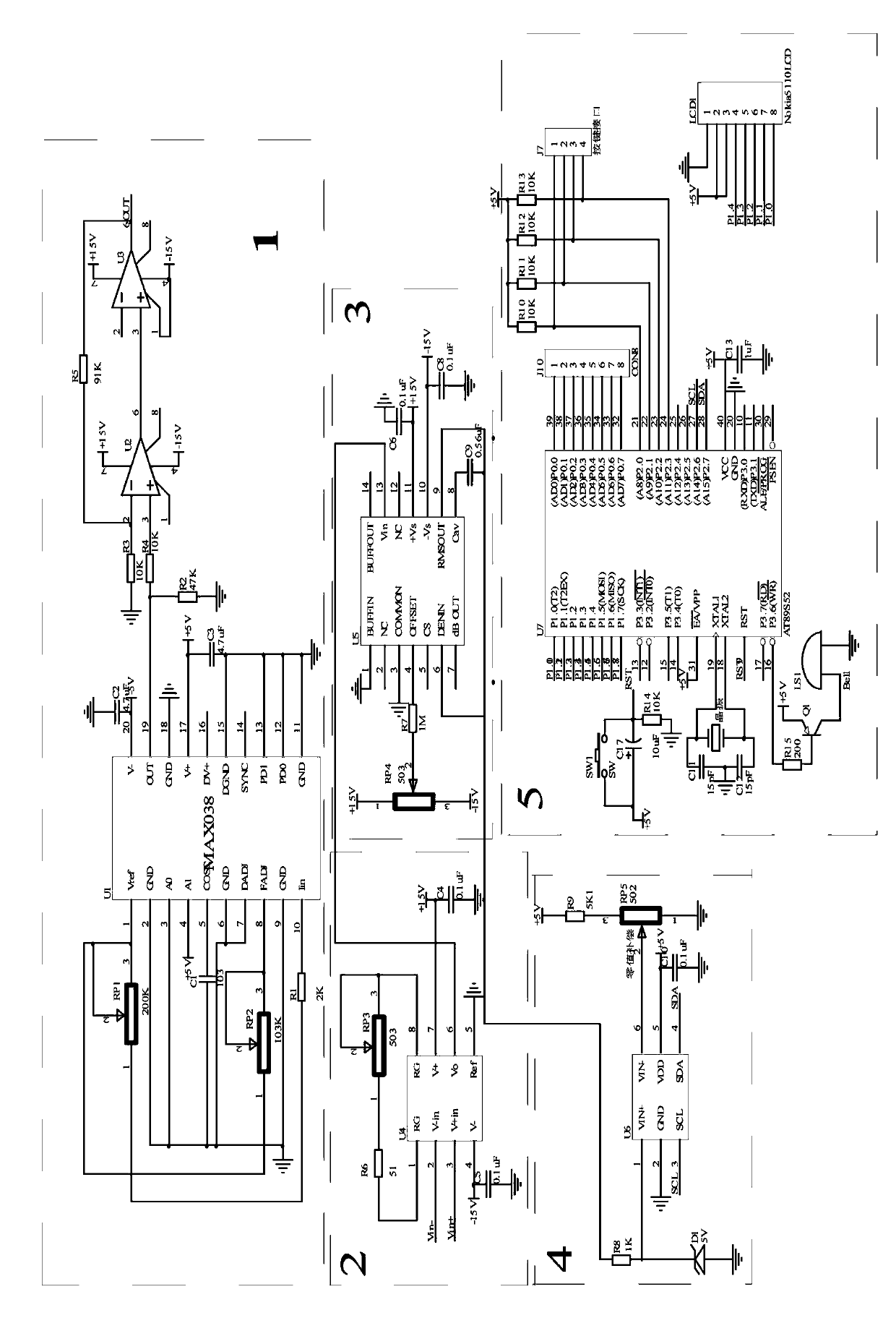

[0024] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

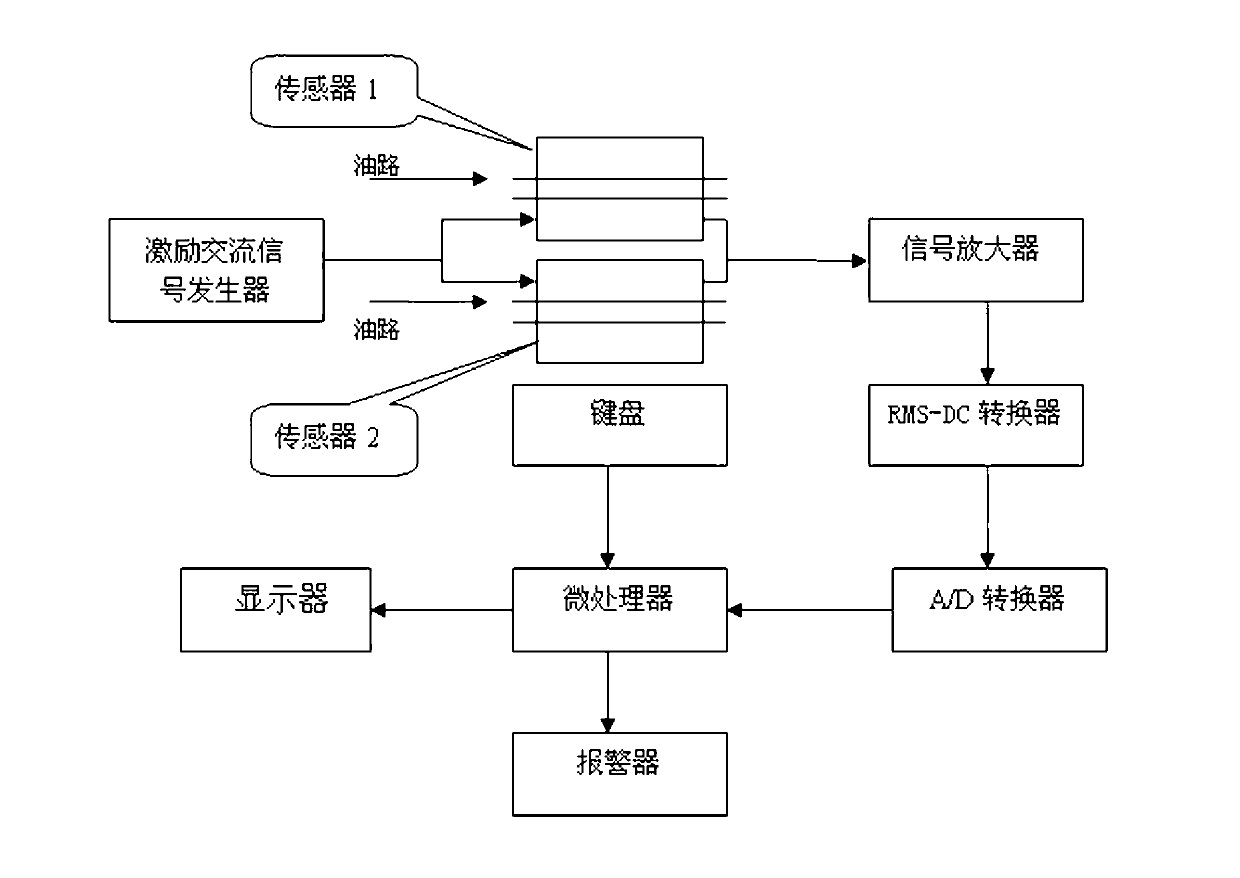

[0025] In the on-line monitoring system for oil metal abrasive particles of the present invention, the sensor is an oil circuit that can pass through the oil; the excitation AC signal generator is connected to the excitation coils of two identical sensors, and the induction coils of the two sensors are connected to the signal amplifier After the signal amplifier, the RMS-DC converter, AD converter, microprocessor and display are connected in sequence, and the microprocessor is also connected to the keyboard and alarm respectively (see figure 1 ).

[0026] The structure of the sensor is specifically as follows: the center of the frame made of magnetically inert material is provided with an oil circuit that can pass through the oil, the excitation coil and the induction coil are coaxially wound on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com