Metallization power capacitor rapid aging testing device

A technology of power capacitor and test device, applied in the field of power electronics, can solve the problems of high cost, poor safety, long test period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

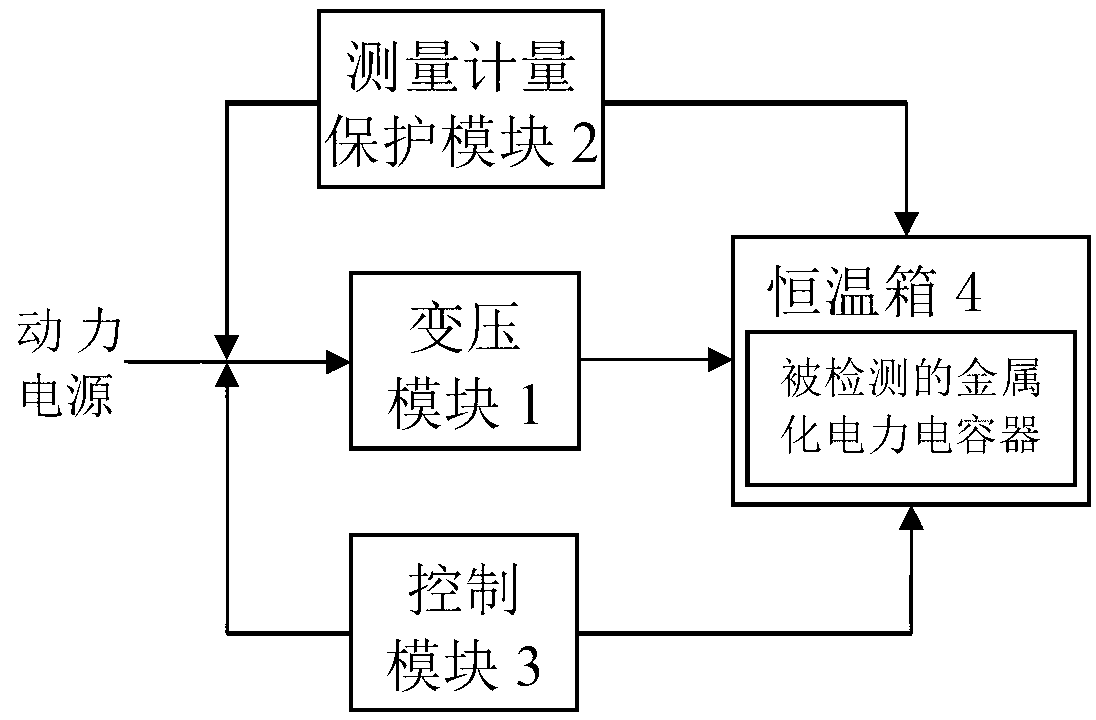

[0047] The structure of the metallized power capacitor rapid aging test device of the present invention is as follows figure 1 As shown, it includes a transformer module 1 , a measurement and protection module 2 , a control module 3 , and a constant temperature box 4 .

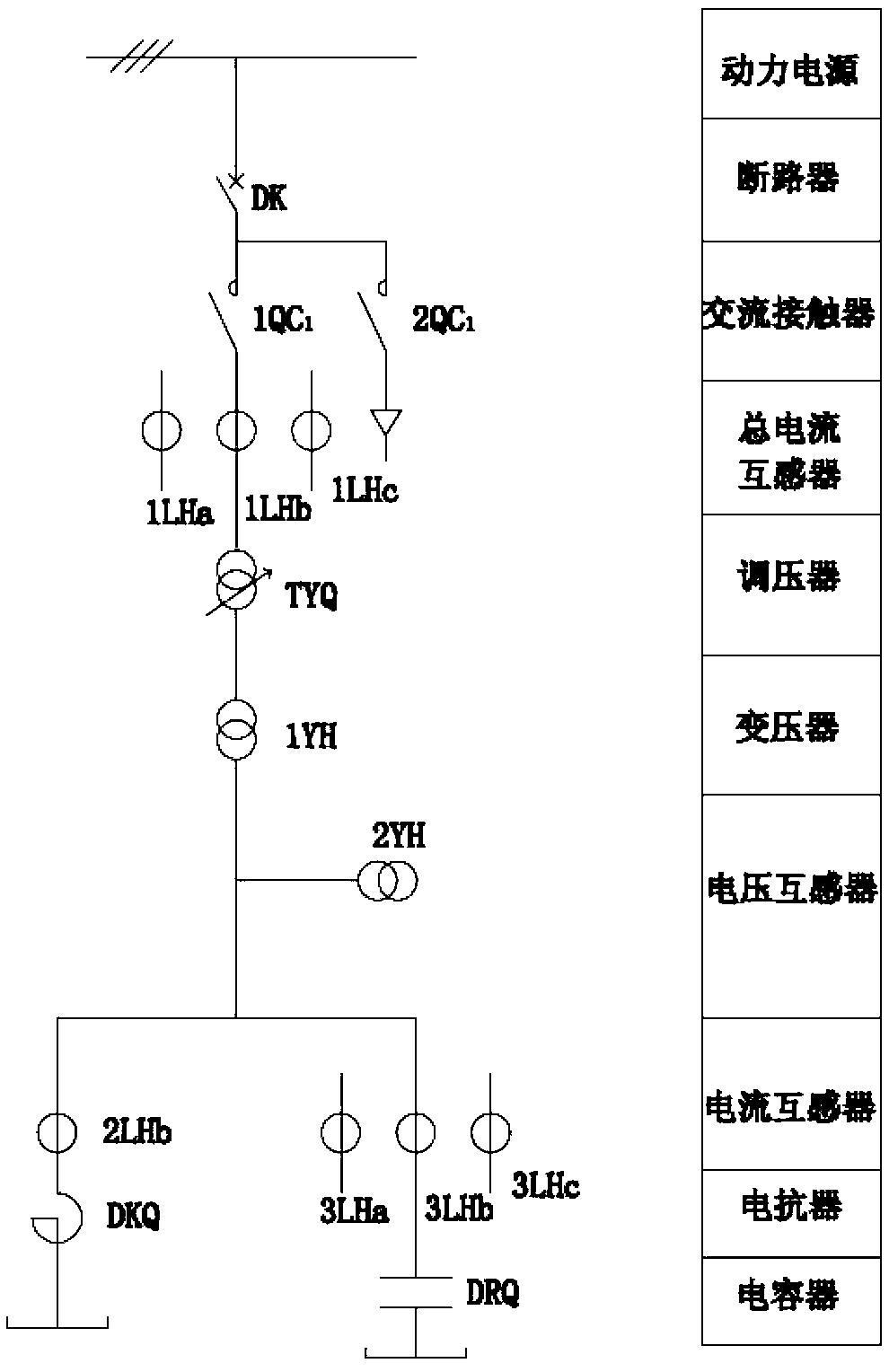

[0048] The voltage transformation module 1 is used to increase the voltage of the power supply to the voltage value required by the test voltage. The voltage transformation module 1 includes a voltage regulator TYQ and a transformer 1YH; the primary side of the voltage regulator TYQ is connected to the AC contactor 1QC conversion contact 1QC 1 The common contact of the voltage regulator TYQ is connected to the primary side of the transformer 1YH, and the secondary side of the transformer 1YH is connected to the detected metallized power capacitor.

[0049] The measurement measurement protection module 2 includes a test time measurement unit, an access voltage measurement unit, a capacitor voltage measurement ...

Embodiment 2

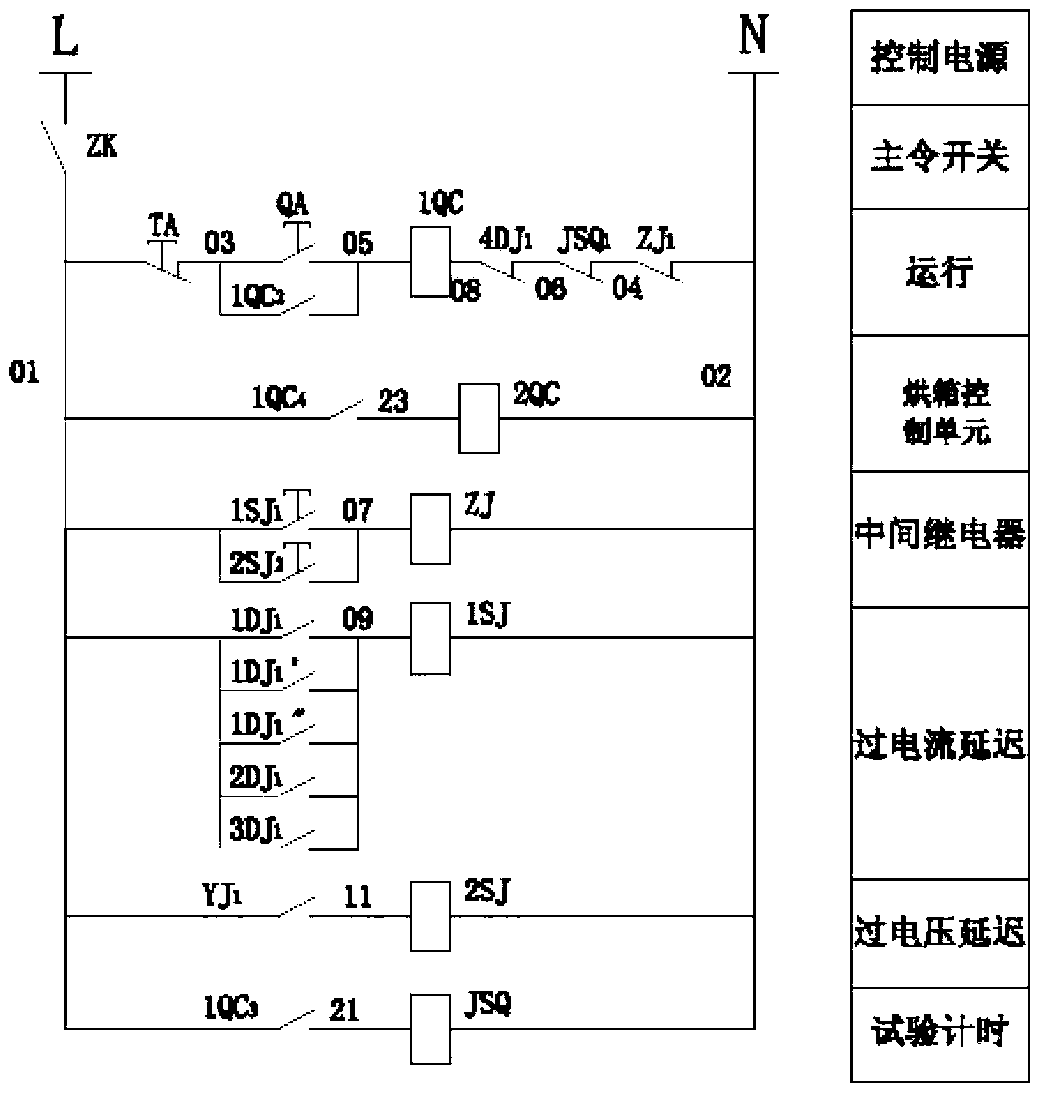

[0065] On the basis of the above embodiments, the control module further includes a work instruction unit. Such as Figure 9 As shown, the work indication unit includes signal lights 1XD, 2XD, 3XD, and the AC contactor 1QC conversion contact 1QC 5 , the AC contactor 2QC changeover contact 2QC 2 ; One end of the signal lamp 1XD is connected to the positive pole of the control power supply, the other end of the signal lamp 1XD is connected to the negative pole of the control power supply, and the AC contactor 1QC conversion contact 1QC 5 The common contact of the control power supply is connected to the positive pole of the control power supply, and the AC contactor 1QC transfer contact 1QC 5 The normally open contact of the signal lamp 2XD is connected to one end of the signal lamp 2XD, the other end of the signal lamp 2XD is connected to the negative pole of the control power supply, and the AC contactor 2QC conversion contact 2QC 2 The common contact of the control power s...

Embodiment 3

[0067] On the basis of the above embodiments, the measurement protection module further includes a display unit for overcurrent, short circuit current and overvoltage signals. Such as Figure 10 As shown, the display unit of the overcurrent, short circuit current and overvoltage signal includes signal relays 1XJ, 2XJ, 3XJ, 4XJ, current relay 1DJ changeover contact 1DJ 2 , Current relay 1DJ' changeover contact 1DJ 2 ', current relay 1DJ "changeover contact 1DJ 2 ", current relay 2DJ changeover contact 2DJ 2 , current relay 3DJ changeover contact 3DJ 2 , Voltage relay YJ changeover contact YJ 2 ; The current relay 1DJ changeover contact 1DJ 2 , The current relay 1DJ' changeover contact 1DJ 2 ', the current relay 1DJ "changeover contact 1DJ 2 "The public contact of "is connected with the public contact of said master switch ZK, and said current relay 1DJ changeover contact 1DJ 2 , The current relay 1DJ' changeover contact 1DJ 2 ', the current relay 1DJ "changeover contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com