LED transient thermal resistance measuring system

A measurement system and transient thermal resistance technology, applied in the field of LED thermal resistance transient measurement system, can solve problems such as large test error, limited in-depth analysis of thermal problems, and inability to measure non-destructive devices, achieving fast measurement time and accurate measurement results. , the effect of a large temperature controllable range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

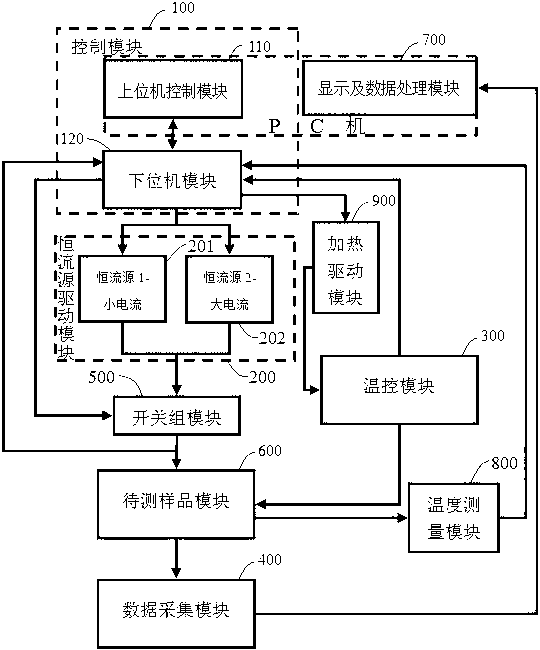

[0027] see figure 1 : This LED transient thermal resistance measurement system includes: a control module (100), a constant current source drive module (200), a temperature control module (300), a data acquisition module (400), a switch group module (500), a test The sample module (600), the display and data processing module (700), the temperature measurement module (800) and the heating drive module (900), are characterized in that: with the control module (100) as the center, the constant current source drive module is connected and controlled (200), heating drive module (900) and switch group module (500); The constant current source drive module (200) receives the PWM control signal from the control module (100), and it is output to the constant current of the sample module to be tested (600). The flow is controlled by the switch group module (500) connected to it; the state of the switch group module (500) is determined by the control module (100) connected to it, and ou...

Embodiment 2

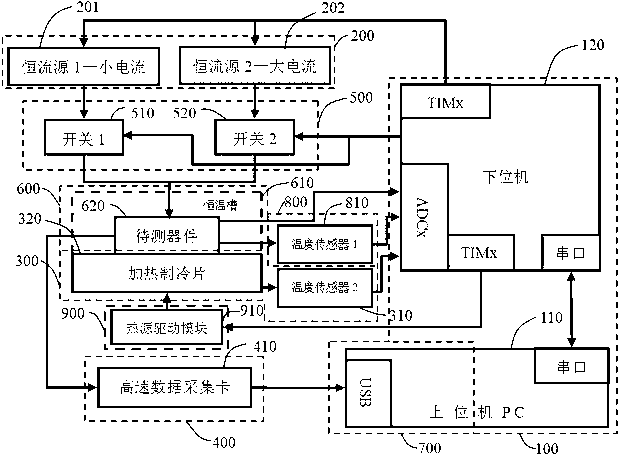

[0029] see figure 1 and figure 2 , the present embodiment is basically the same as Embodiment 1, and the special features are as follows: the control module (100) is composed of a host computer (110) connected to a lower computer (120); through the upper computer (110), the relevant parameters are determined. Setting, data communication between the upper and lower computers through the serial port, the upper computer (110) transmits the parameters to the lower computer (120), and the lower computer (120) according to the relevant parameters and the temperature control module (300) and the switch group module (500) feedback signal, output PWM signal to constant current source drive module (200), heating drive module (900) and output switch control signal; lower computer (100) receives from constant current source drive module (200) and temperature control Feedback signal of the module (300). The input end of the constant current source drive module (200) is connected with th...

Embodiment 3

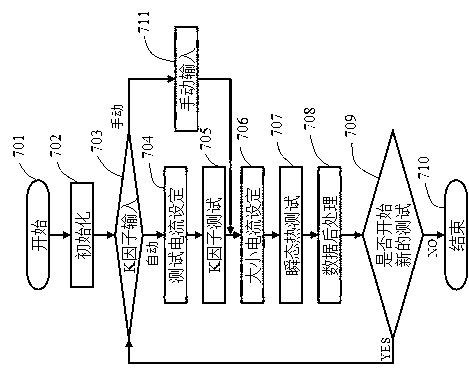

[0031] To obtain a measurement of the transient thermal resistance of the LED, figure 1 and figure 2 The structural diagram of the measurement system of the preferred embodiment of the transient thermal resistance of the LED is given.

[0032] see figure 1 , the system mainly consists of a control module (100), a constant current source drive module (200), a temperature control module (300), a data acquisition module (400), a switch group module (500), a sample module to be tested (600), a display And a data processing module (700), a temperature measurement module (800) and a heating driving module (900). See details figure 1 and figure 2 , in a preferred embodiment of the present invention, the control module (100) mainly consists of a host computer (110) and a lower computer (120); the constant current source drive module (200) mainly includes a constant current source 1-small current (201) , constant current source 2-high current (202); the temperature control modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com