Method for detecting alignment degree between polycrystalline silicon grid and contact hole

A technology of polysilicon gate and contact hole, which is applied in the field of detecting the alignment of polysilicon gate and contact hole, can solve the problems affecting the detection accuracy and errors, and achieve the effect of online manufacturing and yield improvement guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

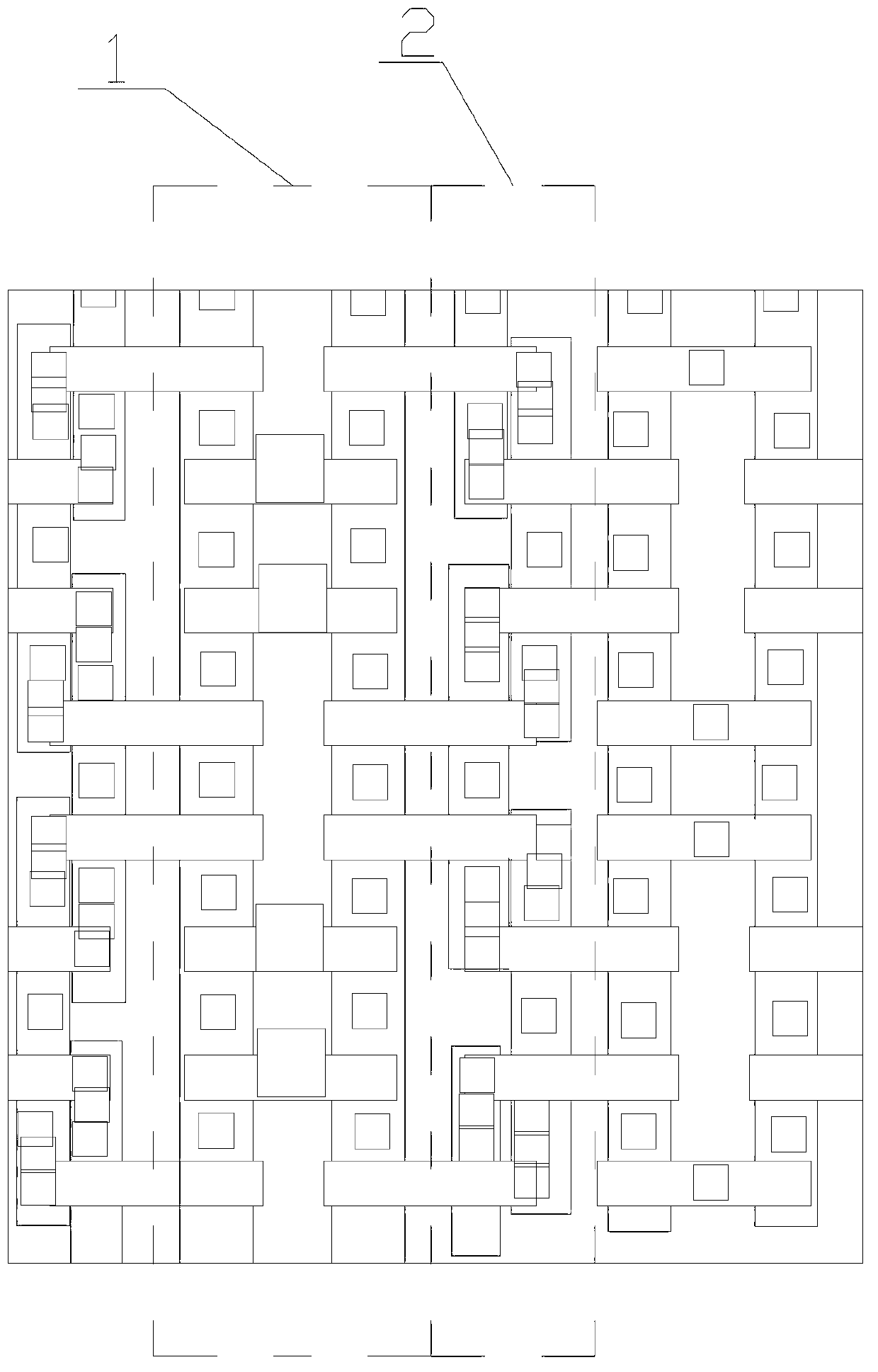

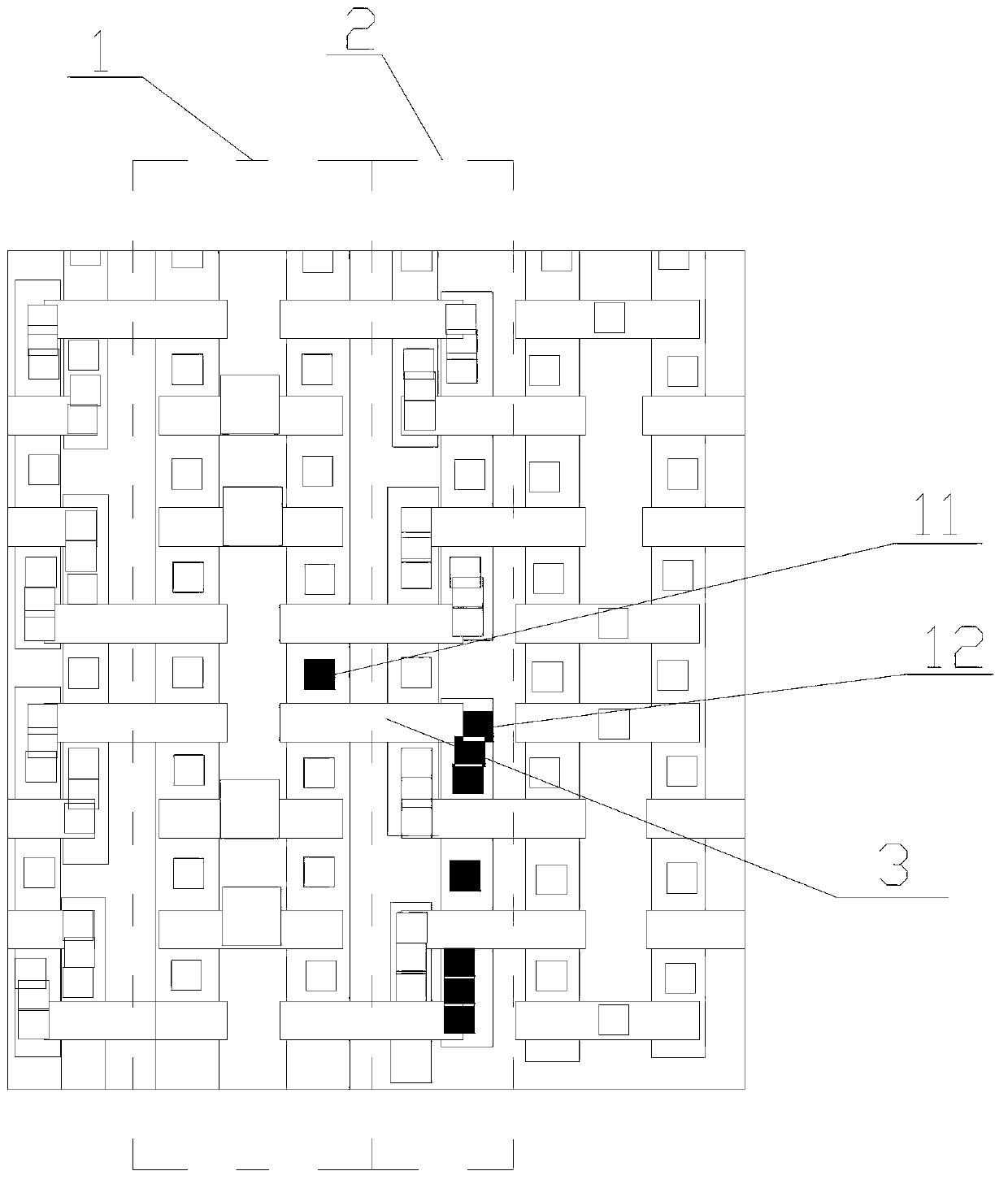

[0036] The preparation process of the test wafer is as follows: a wafer is followed by the normal product wafer tape-out process to the well implantation ion process step, in which the well implantation ion process of the product wafer is slightly changed, specifically, skip Go through the process steps of P-well ion implantation, and change the N-well ion implantation process to non-photoresist ion implantation, so that all the well regions on the substrate of the detection wafer become N-type; then, follow the conventional tape-out process , from the detection wafer tape-out to the active region ion implantation process step, in which the active area ion implantation process of the product wafer is slightly changed, specifically, the ion implantation process step of the N-type active area is skipped , and change the P-type active area ion implantation process to ion implantation without photoresist, so that all the active areas of the detection wafer are P-type active areas, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com