Machine for harvesting corn, peeling corn husks and separating straws, and working method of machine

A corn peeling machine and corn stalk technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of not effectively peeling, affecting the technical effect of corn peeling, etc., and achieves the goal of reducing labor intensity and improving installation structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

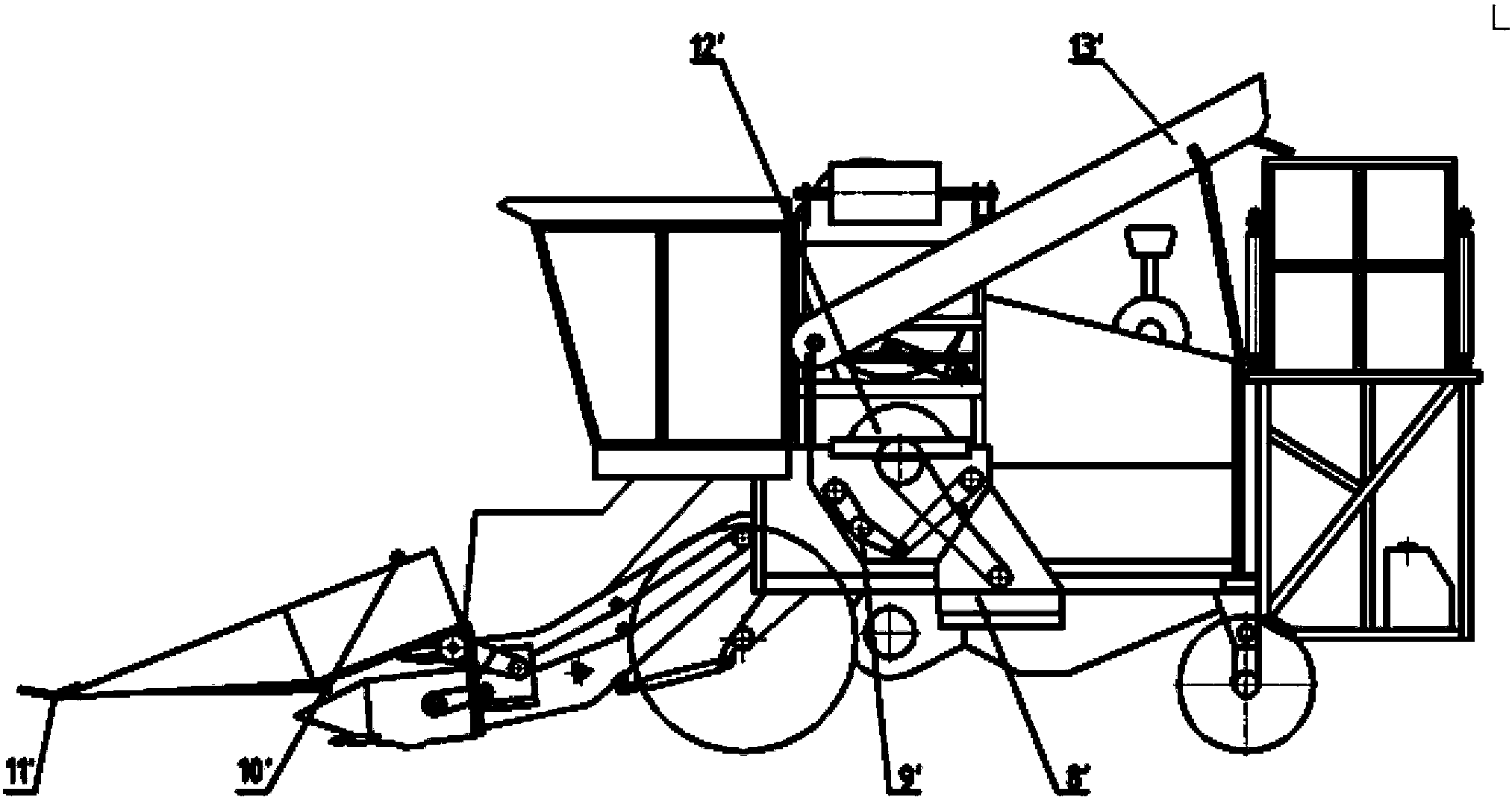

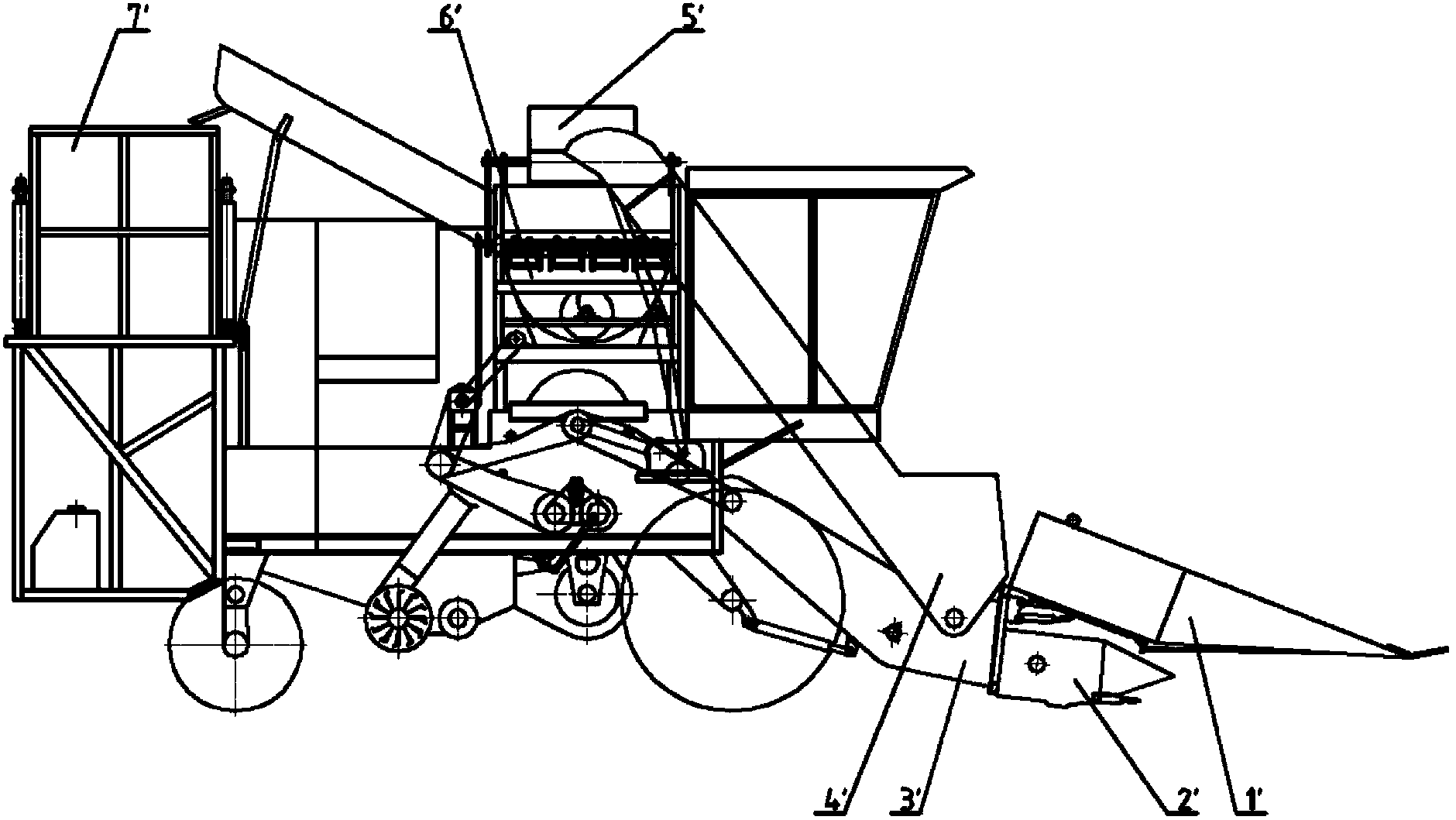

[0064] A corn harvesting, peeling, and straw separator, including a car body, a corn header, a corn ear lifter, a stem transporting device 3', a straw husk separating device 12' and a corn storage bin 7', characterized in that the The corn harvesting, peeling and straw separator described above also includes a corn peeling machine 6';

[0065] The corn header is located at the front of the car body and includes an ear harvester 1' for harvesting corn and a stalk harvester 2' located below the ear harvester for cutting and collecting corn stalks;

[0066] The stem transporting device 3' is used to transport corn stalks, the front part of the transporting stem device 3' is connected to the harvesting platform 2', and the rear part of the transporting device 3' is connected to the straw The skin and flesh separation device 12' is connected;

[0067] The straw husk separation device 12' is used for the husk separation of corn stalks;

[0068] Described corn storage bin 7 ', is p...

Embodiment 2

[0075]A corn harvesting, peeling, and straw separator as described in Example 1, the difference is that, at the top position of the first corn ear elevator 4' and above the corn peeling machine 6', a Fan 5'.

Embodiment 3

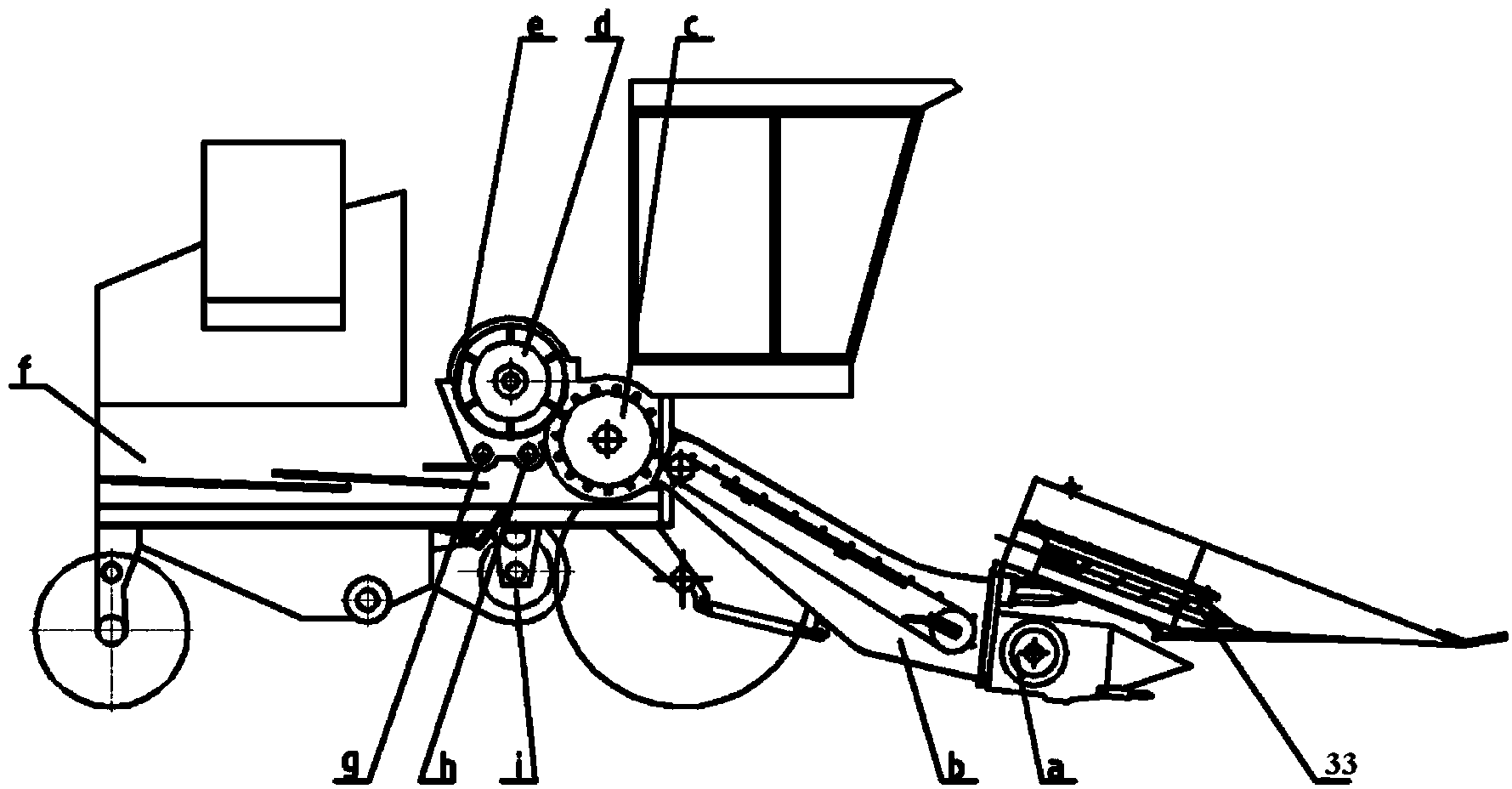

[0077] A corn harvesting, peeling, and straw separator as described in Example 1, the difference is that the peeling steel rod 21 includes a roller body, and a raised steel thread is provided on the surface of the roller body; the peeling rubber roller 22 includes a roller body, a rubber layer is covered on the surface of the roller body, and rubber embossing is arranged on the surface of the rubber layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com