Transmission line tower base welding device

A technology for power transmission lines and welding devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of tower collapse, slag inclusion, inaccurate positioning, etc., achieve strength and anti-overturning resistance, accurate and convenient positioning, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

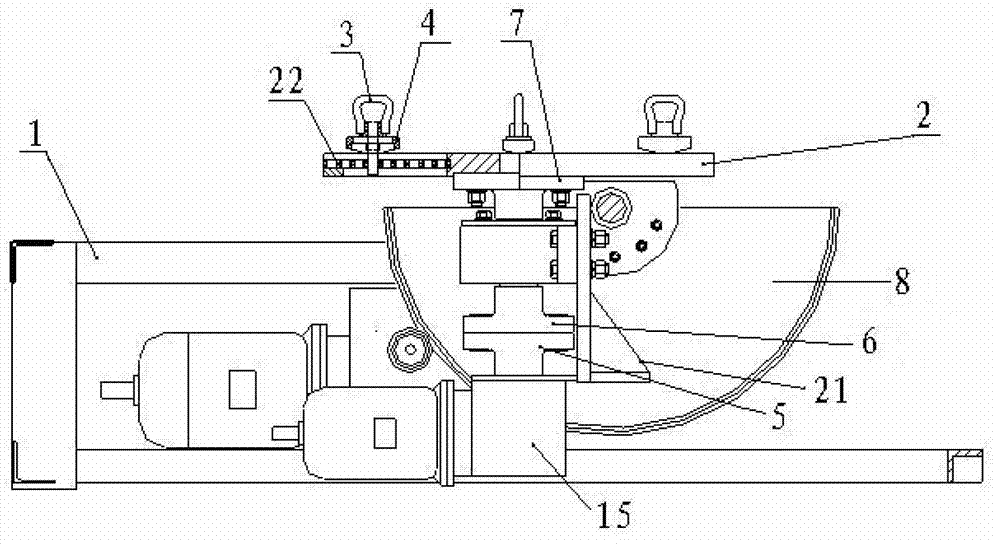

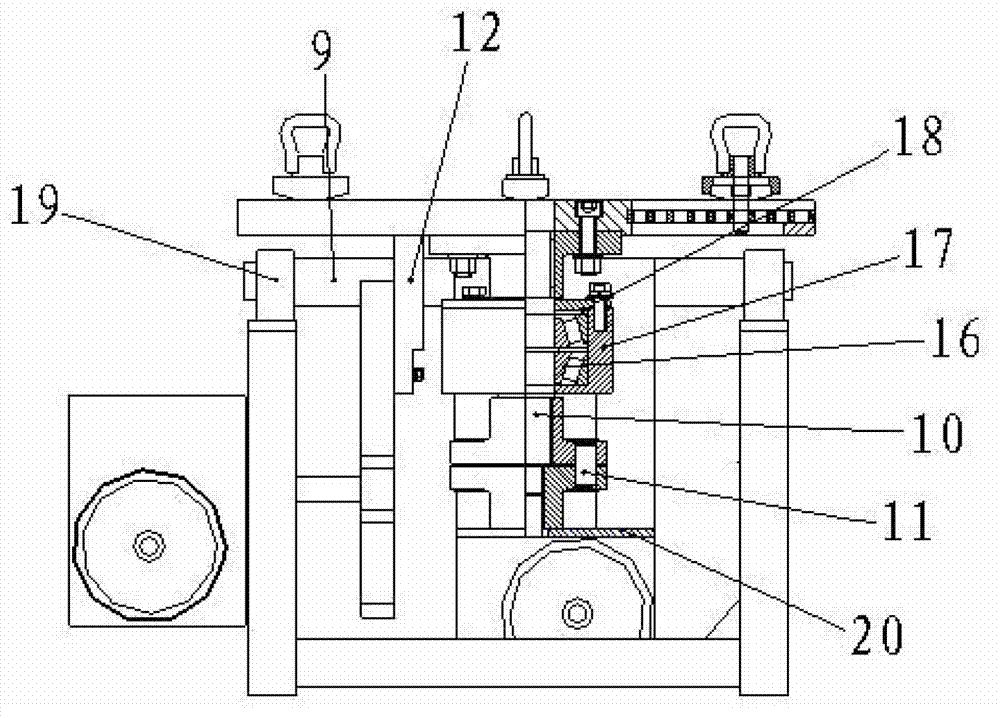

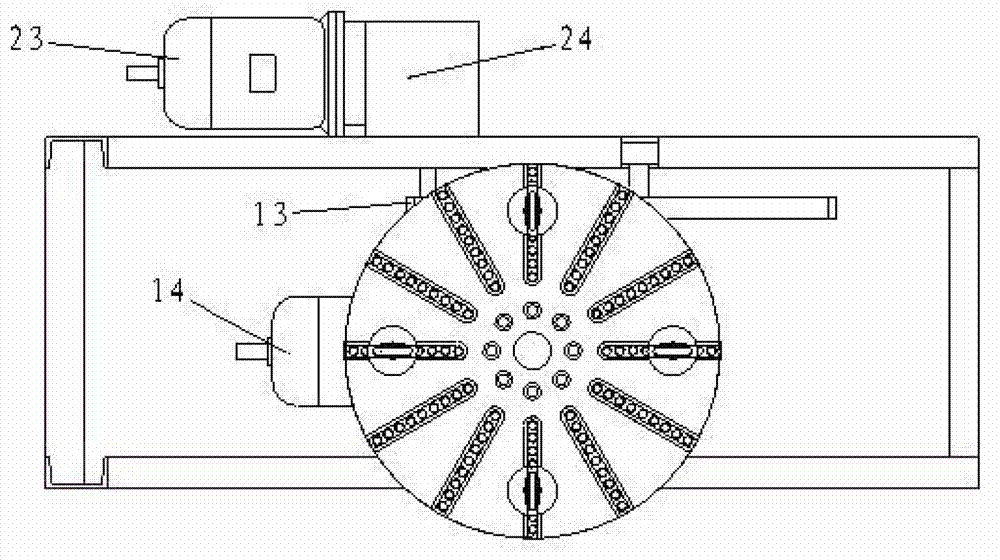

[0025] The technical solutions of the present invention will be further described through the drawings and examples below.

[0026] Such as Figure 1 to Figure 10 As shown, the transmission line iron tower tower welding device of the present invention includes an anti-tilt frame 1, a working platform 2, a screw rod 3 with a handle, a conical surface briquetting block, a lower back wheel 5, a middle back wheel 6, and an upper back wheel 7. Semicircular large gear 8, turning shaft 9, rotating shaft 10, pin 11, connecting flange 12, pinion gear 13, rotating motor 14, rotating gearbox 15, bearing 16, bearing seat 17, bearing end cover 18, sliding bearing 19. Reducer bottom plate 20, bottom plate 21, T-shaped groove insert 22, turning motor 23, turning gearbox 24, etc.

[0027] Its structure and connection method are:

[0028] Described overturning motor 23 is fixedly connected on the input end of overturning gearbox 24, and pinion 13 is sleeved on the output shaft of overturning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com