Printing device combined with screen printing and digital printing and printing method thereof

A technology of digital printing and screen printing, applied in printing devices, copying/marking methods, printing and other directions, can solve the problems that the printing accuracy cannot reach digital printing, the flat screen printing speed is slow, and the structure is complicated, and the printing efficiency can be reduced. , reliable performance, reasonable structure design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

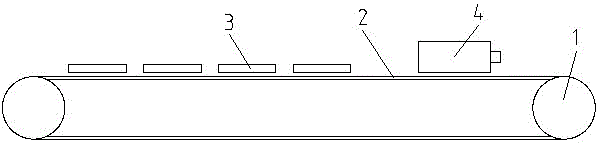

[0023] see figure 1 In this embodiment, the printing device combining screen printing and digital printing includes a frame, a rotating roller 1, a conveyor belt 2, a screen printing mechanism 3 and a digital printing mechanism 4, wherein the rotating roller 1 is installed on the frame, Driven by the driving mechanism, the rotating roller 1 can rotate.

[0024] The conveyor belt 2 in this embodiment is installed on the rotating roller 1, and when the rotating roller 1 rotates, it can drive the conveyor belt 2 to rotate, so as to achieve the purpose of conveying fabrics.

[0025] The screen printing mechanism 3 in the present embodiment is installed on the frame, and the screen printing mechanism 3 cooperates with the conveyor belt 2. When the fabric is delivered to the bottom of the screen printing mechanism 3 by the conveyor belt 2, the screen printing mechanism 3 Able to print fabrics.

[0026] The digital printing mechanism 4 in the present embodiment is installed on the ...

Embodiment 2

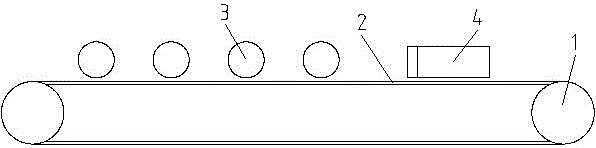

[0034] see figure 2 In this embodiment, the printing device combining screen printing and digital printing includes a frame, a rotating roller 1, a conveyor belt 2, a screen printing mechanism 3 and a digital printing mechanism 4, wherein the rotating roller 1 is installed on the frame, Driven by the driving mechanism, the rotating roller 1 can rotate.

[0035] The conveyor belt 2 in this embodiment is installed on the rotating roller 1, and when the rotating roller 1 rotates, it can drive the conveyor belt 2 to rotate, so as to achieve the purpose of conveying fabrics.

[0036] The screen printing mechanism 3 in the present embodiment is installed on the frame, and the screen printing mechanism 3 cooperates with the conveyor belt 2. When the fabric is delivered to the bottom of the screen printing mechanism 3 by the conveyor belt 2, the screen printing mechanism 3 Able to print fabrics.

[0037] The digital printing mechanism 4 in the present embodiment is installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com