Semi-coke and biomass mixed type coal and preparation method thereof

A biomass and hybrid technology, applied in the direction of biofuel, waste fuel, solid fuel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

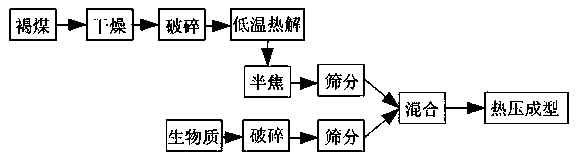

Method used

Image

Examples

Embodiment 1

[0034] Table 1 Test results of semi-coke and biomass mixed briquettes

[0035] Drop strength / % Compressive strength / N Calorific value Q gr,d / (MJ / ㎏) 87.59 15.1 25.90

[0036] Example 2

[0037] The ratio of semi-coke and biomass mixed briquettes in this embodiment is: 35 parts by mass of biomass and 65 parts by mass of semi-coke. The semi-focus is the same as in Example 1. The preparation method of the semi-coke and biomass mixed briquettes is the same as that of Example 1, except that the pressure of hydroforming is 100 MPa.

[0038] The mixed briquettes of semi-coke and biomass in this embodiment are high-strength coals, and the detection results of the resulting products are as shown in Table 2:

Embodiment 2

[0040] Drop strength / % Compressive strength / N Calorific value Q gr,d / (MJ / ㎏) 87.57 15.3 25.90

[0041] Example 3

[0042] The ratio of semi-coke and biomass mixed briquettes in this embodiment is: 35 parts by mass of biomass and 65 parts by mass of semi-coke. The semi-focus is the same as in Example 1. The preparation method of the semi-coke and biomass mixed briquette is the same as that of Example 1, except that the pressure of hydroforming is 120 MPa.

[0043] The mixed briquettes of semi-coke and biomass in this embodiment are high-strength coals, and the detection results of the resulting products are as shown in Table 3:

Embodiment 3

[0045] Drop strength / % Compressive strength / N Calorific value Q gr,d / (MJ / ㎏) 87.01 15.5 25.90

[0046] Example 4

[0047] The ratio of semi-coke and biomass mixed briquettes in this embodiment is: 35 parts by mass of biomass and 65 parts by mass of semi-coke. The semi-focus is the same as in Example 1. The preparation method of the semi-coke and biomass mixed briquette is the same as that of Example 1, except that the molding temperature is 290°C.

[0048] The mixed briquettes of semi-coke and biomass in this embodiment are high-strength coals, and the detection results of the resulting products are as shown in Table 4:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com